Method for producing super fine calcium carbonate

An ultra-fine calcium carbonate, wet process technology, applied in chemical instruments and methods, inorganic pigment treatment, dyed organosilicon compound treatment, etc., to achieve the effect of improving surface properties, speeding up, and improving dispersion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

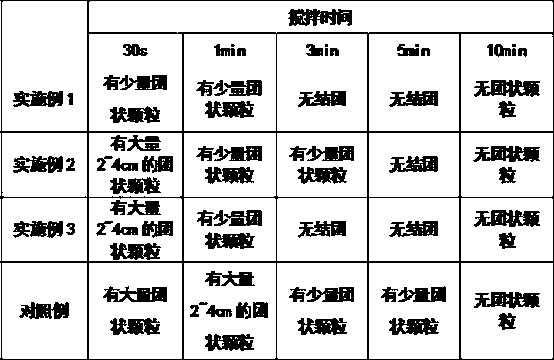

Examples

Embodiment 1

[0022] A method for wet production of superfine calcium carbonate, comprising the following steps:

[0023] S1. Coarsely crushing and pulverizing the calcite raw material to obtain calcite powder of 100-200 mesh;

[0024] S2. Grinding with a micropowder mill, and sieving ultrafine powders with a particle size of <5 μm after the milling is completed;

[0025] S3. Add water to the ultrafine powder to form a slurry, the weight ratio of water and ultrafine powder is 100:45, use a wet grinder to grind, and add zirconia microbeads and silane coupling to the wet grinder at the same time. Coupling agent, sodium pyrophosphate, frictional silicon dioxide and phosphodiester salt are ground, and the weight ratio of silane coupling agent, sodium pyrophosphate, frictional silicon dioxide, phosphodiester salt and ultrafine powder is 0.3: 0.08:0.04:0.08:45, grinding time 45min, temperature 56℃;

[0026] S4. passing the slurry obtained after wet grinding through a vibrating sieve to obtain u...

Embodiment 2

[0029] A method for wet production of superfine calcium carbonate, comprising the following steps:

[0030] S1. Coarsely crushing and pulverizing the calcite raw material to obtain calcite powder of 100-200 mesh;

[0031] S2. Grinding with a micropowder mill, and sieving ultrafine powders with a particle size of <5 μm after the milling is completed;

[0032] S3. Add water to the ultrafine powder to form a slurry, the weight ratio of water and ultrafine powder is 100:50, use a wet grinder to grind, and add zirconia microbeads and silane coupling to the wet grinder at the same time. Coupling agent, sodium pyrophosphate, frictional silicon dioxide and phosphate diester salt are ground, and the weight ratio of silane coupling agent, sodium pyrophosphate, frictional silicon dioxide, phosphodiester salt and ultrafine powder is 0.2: 0.05:0.05:0.1:50, grinding time 50min, temperature 60℃;

[0033] S4. passing the slurry obtained after wet grinding through a vibrating sieve to obtain...

Embodiment 3

[0036] A method for wet production of superfine calcium carbonate, comprising the following steps:

[0037] S1. Coarsely crushing and pulverizing the calcite raw material to obtain calcite powder of 100-200 mesh;

[0038] S2. Grinding with a micropowder mill, and sieving ultrafine powders with a particle size of <5 μm after the milling is completed;

[0039] S3. Add water to the ultrafine powder to form a slurry, the weight ratio of water and ultrafine powder is 90:30, use a wet grinder to grind, and add zirconia microbeads and silane distillate to the wet grinder at the same time. Coupling agent, sodium pyrophosphate, frictional silicon dioxide and phosphoric acid diester salt are ground, and the weight ratio of silane coupling agent, sodium pyrophosphate, frictional silicon dioxide, phosphoric acid diester salt and ultrafine powder is 0.5: 0.1:0.03:0.05:30, grinding time 40min, temperature 50℃;

[0040] S4. passing the slurry obtained after wet grinding through a vibrating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com