Three-dimensional graphene-based composite wave absorbing materials, and preparation method thereof

A composite wave-absorbing material and graphene composite technology, applied in chemical instruments and methods, other chemical processes, etc., to achieve the effects of low wave-absorbing frequency band, adjustable electromagnetic parameters, and light specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

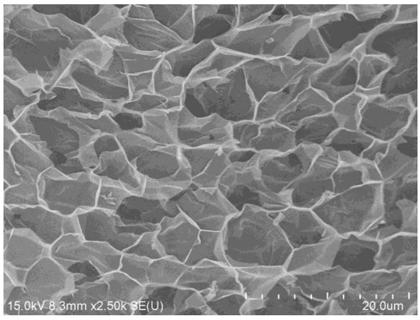

[0030] Weigh ferric nitrate nonahydrate, cobalt nitrate hexahydrate and polyvinylpyrrolidone powder according to the mass ratio of 1.5:0.8:1, then dissolve in deionized water and stir ultrasonically for 10 minutes to obtain a mixed solution, and then place the mixed solution in a blast drying oven for 80 ℃ heat preservation until completely dry, then grind the dried product into powder and transfer the powder to a crucible, place the crucible in a tube furnace and heat it to 1000 ℃ at a heating rate of 5 ℃ / min in Ar atmosphere, keep After 2 hours, the black foamy product was collected after the tube furnace was cooled, and the magnetic nano-iron-cobalt alloy / three-dimensional graphene composite absorbing material was obtained.

Embodiment 2

[0032] Weigh ferric nitrate nonahydrate, (cobalt nitrate hexahydrate and nickel nitrate hexahydrate) and polyvinylpyrrolidone powder by mass ratio 1.5:1.0:1, wherein the raw material ratio 0.8 is the mass sum of cobalt nitrate hexahydrate and ferric nitrate hexahydrate Proportion; then dissolved in deionized water and ultrasonically stirred for 15 minutes to obtain a mixed solution, then placed the mixed solution in a blast drying oven at 80°C to keep warm until completely dry, then ground the dried product into a powder and transferred the powder to In the crucible, the crucible is placed in a tube furnace and heated to 1000 °C at a heating rate of 5 °C / min in an Ar atmosphere, and kept for 2 hours. After the tube furnace cools down, a black foamy product is collected to obtain a magnetic nano-iron-cobalt-nickel alloy / Three-dimensional graphene composite absorbing material.

Embodiment 3

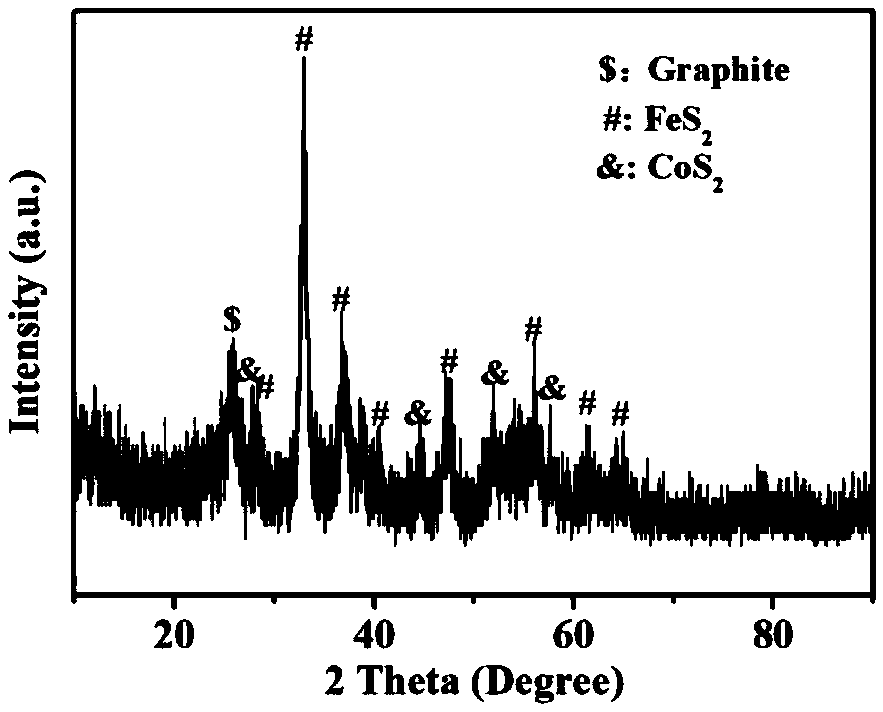

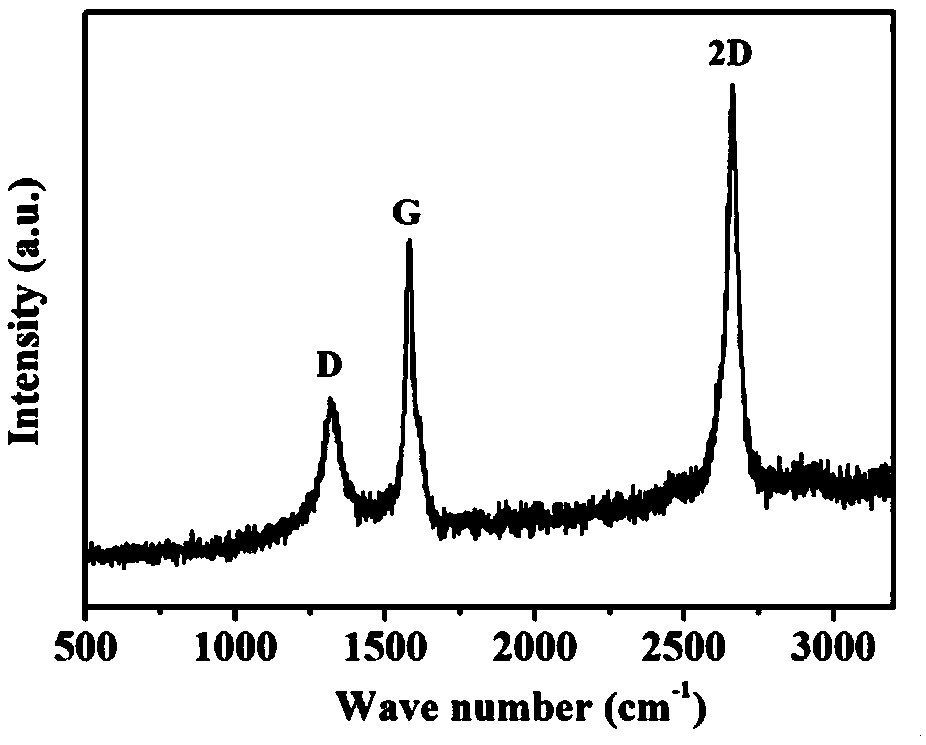

[0034] The magnetic nano-iron-cobalt alloy / three-dimensional graphene composite wave-absorbing material prepared in Example 1 was uniformly mixed with sublimed sulfur at a mass ratio of 1:1, then placed in a tube furnace, and heated at a rate of 2°C / min in an Ar atmosphere. Heating at a rate of 300°C and keeping it warm for 3 hours, after the tube furnace is cooled to room temperature, the foamy product is collected, which is the magnetic nano cobalt iron sulfide / three-dimensional graphene composite wave-absorbing material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com