NASICON structure sodium ion solid electrolyte, preparation method thereof, and solid state sodium ion battery

A technology of solid electrolyte and sodium ions, which can be used in the manufacture of non-aqueous electrolyte batteries, electrolyte batteries, electrolytes, etc., and can solve problems that limit the application of solid-state sodium batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

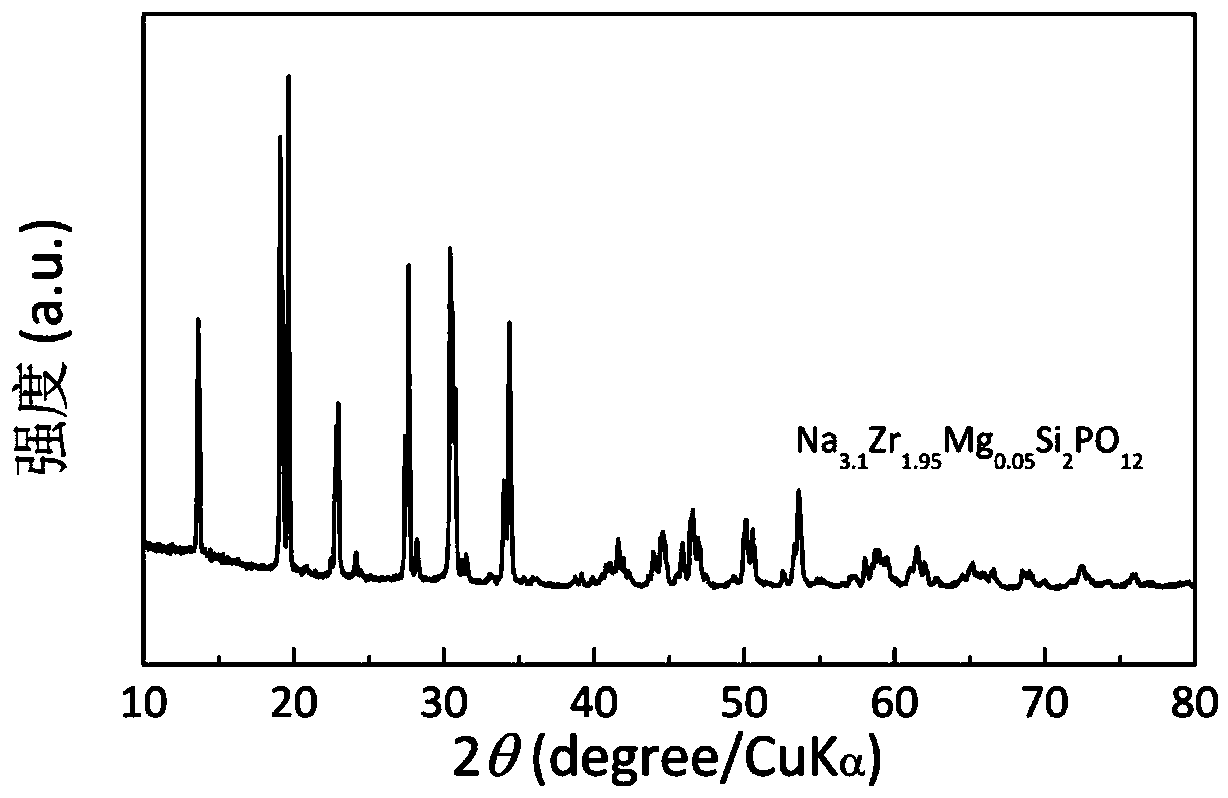

[0141] Preparation of Na by solid phase method 3.1 [Zr 1.95 Mg 0.05 ]Si 2 PO 12 solid electrolyte material.

[0142] According to the molar ratio of Na source, P source, Zr source, Si source and metal oxide is 1.55:1:1.95:2:0.05, 0.0155mol Na 2 CO 3 , 0.01mol NH 4 h 2 PO 4 , 0.0195mol ZrO 2 , 0.02mol SiO 2 Mix with 0.0005mol MgO, ball mill evenly and dry. The obtained mixture was placed in a muffle furnace, heated to 900° C. for 6 hours in an air atmosphere, cooled and then ball-milled and dried to obtain a precursor powder. The precursor powder was pressed into tablets, then placed in a muffle furnace, and heat-treated at 1225 °C for 12 hours in an air atmosphere to obtain a sheet-shaped NASICON structure sodium ion solid electrolyte sample.

[0143] The obtained flake NASICON structure sodium ion solid electrolyte sample is subjected to scanning electron microscope scanning analysis, and the results are as follows: figure 1 as shown, figure 1 Cross-sectional SE...

Embodiment 2

[0150] Preparation of Na by solid phase method 3.2 [Zr 1.9 Mg 0.1 ]Si 2 PO 12 solid electrolyte material.

[0151] According to the molar ratio of Na source, P source, Zr source, Si source and metal oxide as 1.92:1:1.9:2:0.1, 0.0192molNa 2 CO 3 , 0.01mol (NH 4 ) 2 HPO 4 , 0.019molZrO 2 , 0.02mol SiO 2 Mix with 0.001mol MgO, ball mill evenly and dry. The obtained mixture was placed in a muffle furnace, heated to 950° C. for 6 hours in an air atmosphere, cooled and then ball-milled and dried to obtain a precursor powder. The precursor powder was pressed into tablets, then placed in a muffle furnace, and heat-treated at 1225 °C for 12 hours in an air atmosphere to obtain a sheet-shaped NASICON structure sodium ion solid electrolyte sample.

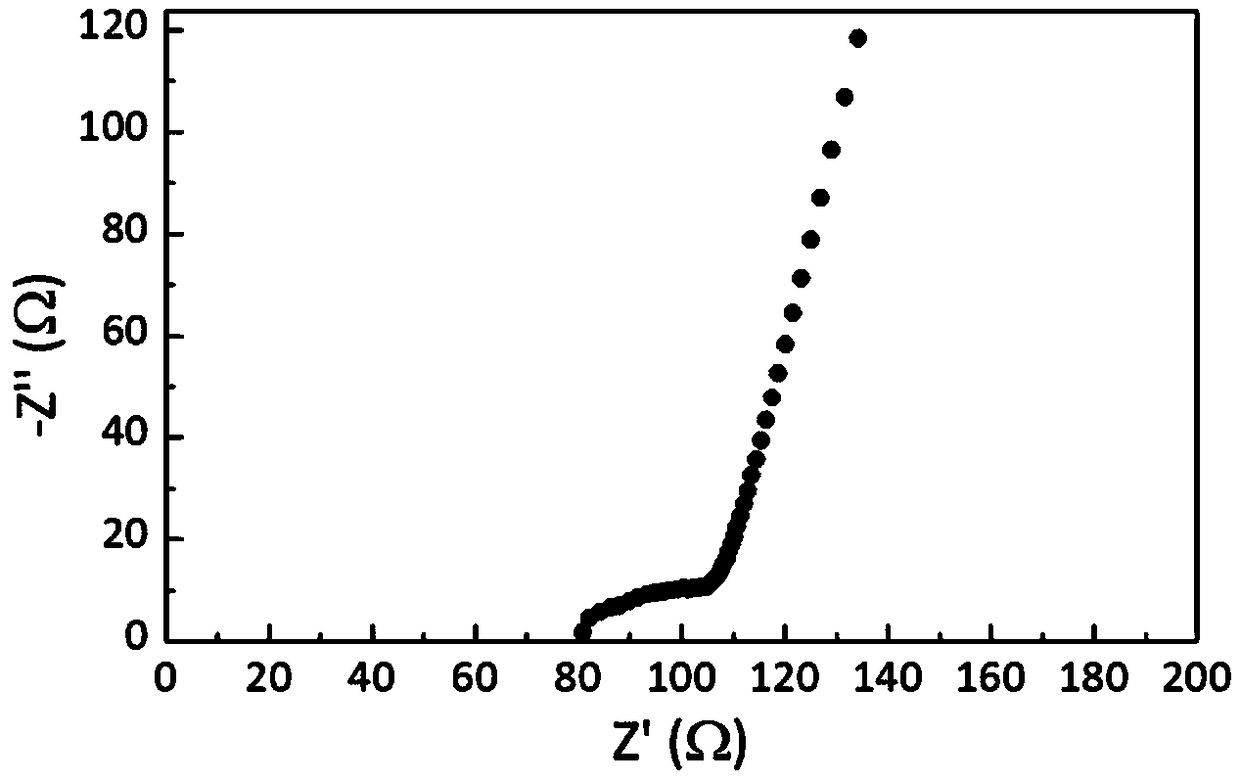

[0152] The flaky NASICON structure sodium ion solid electrolyte is polished, cleaned, and dried, and then gold is sputtered on both sides of the dried electrolyte as a blocking electrode, and an AC impedance test is performed at r...

Embodiment 3

[0157] Preparation of Na by solid phase method 3.4 [Zr 1.9 Mg 0.1 ] Si 2.2 P 0.8 o 12 solid electrolyte material.

[0158] According to the molar ratio of Na source, P source, Zr source, Si source and metal oxide is 3.4:0.88:1.9:2.2:0.1, 0.034mol NaHCO 3 , 0.0088mol H 3 PO 4 , 0.019mol ZrO 2 , 0.022mol SiO 2 Mix with 0.001mol MgO, ball mill evenly and dry. The obtained mixture was placed in a muffle furnace, heated to 850° C. for 10 h in an air atmosphere, cooled and then ball-milled and dried to obtain a precursor powder. The precursor powder was pressed into tablets, then placed in a muffle furnace, and heat-treated at 1275 °C for 8 hours in an air atmosphere to obtain a sheet-shaped NASICON structure sodium ion solid electrolyte sample.

[0159] The obtained flake NASICON structure sodium ion solid electrolyte sample is subjected to scanning electron microscope scanning analysis, and the results are as follows: Figure 5 as shown, Figure 5 Cross-sectional SEM ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com