Method for removing residual organophosphorus pesticides from fruit juice

An organophosphorus pesticide and fruit juice technology, applied in food science, food preservation, application, etc., can solve the problems of low pesticide degradation and removal rate, low degradation efficiency, long degradation time, etc., to achieve rich pore size, large adsorption capacity, The effect of enhancing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

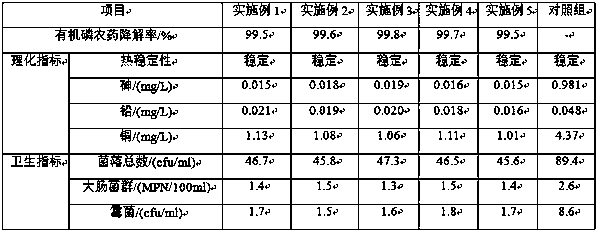

Examples

Embodiment 1

[0023] Preparation of low-crosslinking complex: Add 120 parts of gelatin solution with a mass fraction of 1%, 28 parts of acrylate, 30 parts of vinylpyridine, 3 parts of divinylbenzene, 0.2 parts of benzoyl peroxide, After 11.5 parts of liquid wax, stir and mix, then react at 80°C for 12h, then cool, filter, wash with hot water, filter dry the complex, extract with absolute ethanol for 9h, and finally vacuum dry at 60°C for 2h Obtain low cross-linked complexes;

[0024] Preparation of ultra-high cross-linked basic resin: Add the low-cross-linked compound prepared in a to reaction kettle B, swell with chloromethyl ether, and then add anhydrous AlCl 3 Add 23 parts into reaction kettle B in batches, react at 34°C for 10.5h, then cool, filter, and extract with absolute ethanol for 10h, then wash until neutral, then add excess ethylenediamine at 110°C After reacting for 9 hours, wash with distilled water until neutral, and finally dry in vacuum at 60°C for 2 hours to obtain an ult...

Embodiment 2

[0030] Preparation of low-crosslinking complex: Add 105 parts of gelatin solution with a mass fraction of 1%, 22 parts of acrylate, 35 parts of vinylpyridine, 2.5 parts of divinylbenzene, 0.18 parts of benzoyl peroxide, After 12 parts of liquid wax, stir and mix, then react at 80°C for 11h, then cool, filter, wash with hot water, filter dry the complex, extract with absolute ethanol for 8.5h, and finally vacuum dry at 52°C 2h to obtain low cross-linked complex;

[0031] Preparation of ultra-high cross-linked basic resin: Add the low-cross-linked compound prepared in a to reaction kettle B, swell with chloromethyl ether, and then add anhydrous AlCl 3 Add 21 parts in batches to reactor B, react at 35°C for 11.5h, then cool, filter, and extract with absolute ethanol for 8h, then wash until neutral, then add excess ethylenediamine at 115°C After reacting for 8.5 hours, wash with distilled water until neutral, and finally dry in vacuum at 53°C for 2 hours to obtain an ultra-high c...

Embodiment 3

[0037] Preparation of low-crosslinking complex: Add 100 parts of gelatin solution with a mass fraction of 1%, 25 parts of acrylate, 32 parts of vinylpyridine, 4 parts of divinylbenzene, 0.19 parts of benzoyl peroxide, Stir and mix 11 parts of liquid wax, then react at 80°C for 10.5h, then cool, filter, wash with hot water, filter to dry the complex, extract with absolute ethanol for 10h, and finally vacuum dry at 55°C 2h to obtain low cross-linked complex;

[0038] Preparation of ultra-high cross-linked basic resin: Add the low-cross-linked compound prepared in a to reaction kettle B, swell with chloromethyl ether, and then add anhydrous AlCl 3 Add 20 parts in batches to reactor B, react at 32°C for 11h, then cool, filter, and extract with absolute ethanol for 9.5h, then wash until neutral, then add excess ethylenediamine at 120°C After reacting for 8 hours, wash with distilled water until neutral, and finally dry in vacuum at 50°C for 2 hours to obtain an ultra-high cross-li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com