Preparation method of fermented pickled fresh ginger in bag

A technology for ginger and kimchi, applied in the fields of biotechnology and food, can solve the problems of uncontrollable fermentation, unstable color and flavor, large discharge of high-salt and high-acid wastewater, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

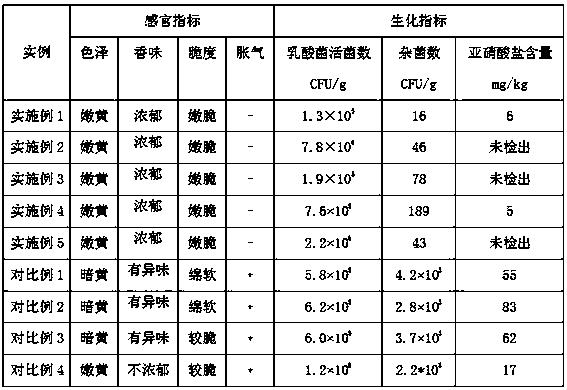

Examples

Embodiment 1

[0090] Example 1 Preparation of fermented ginger kimchi in a 200kg bag

[0091] A. Pretreatment

[0092] Wash the fresh ginger to remove impurities and set aside;

[0093] B. Disinfection and cleaning

[0094] The ginger pretreated in step A is disinfected with an aqueous solution of dichloroisocyanuric acid with a mass concentration of 1.00‰ for 3 minutes, and the total number of microorganisms is controlled to ≤300CFU / g; then rinsed with water for 4 minutes and drained to obtain ginger Raw materials, spare;

[0095] C. Preparation of fermentation solution

[0096] a. Weighing

[0097] Weigh 65% of raw ginger, 130Kg; prepare 35% of fermentation solution, 70kg;

[0098] Weigh the following materials based on the total weight of 200Kg:

[0099] Sodium ethylenediaminetetraacetate 0.05g / kg, 10g;

[0100] Potassium sorbate 0.20g / kg, 40g;

[0101] Sodium metabisulfite 0.10g / kg, 100g;

[0102] Sodium dehydroacetate 0.05g / kg, 10g;

[0103] Non-iodine salt 50.0g / kg, 10Kg;

[0104] Citric acid 1.00g / kg,...

Embodiment 2

[0116] Example 2 Preparation of fermented ginger kimchi in a 500kg bag

[0117] A. Pretreatment

[0118] Wash the fresh ginger to remove impurities and set aside;

[0119] B. Disinfection and cleaning

[0120] The ginger pretreated in step A was disinfected with an aqueous solution of trichloroisocyanuric acid with a mass concentration of 0.01‰ for 5 minutes, and the total number of microorganisms was controlled to ≤300CFU / g; then rinsed with water for 3 minutes and drained to obtain ginger Raw materials, spare;

[0121] C. Preparation of fermentation solution

[0122] a. Weighing

[0123] Weigh 30% of raw ginger, 150Kg; prepare 70% of fermentation solution, 350kg;

[0124] Weigh the following materials based on the total weight of 500Kg:

[0125] Sodium ethylenediaminetetraacetate 0.20g / kg, 100g;

[0126] Potassium sorbate 0.50g / kg, 250g;

[0127] Sodium metabisulfite 0.05g / kg, 25g;

[0128] Sodium dehydroacetate 0.30g / kg, 150g;

[0129] No iodine salt 130.0g / kg, 65Kg;

[0130] Citric acid 8.0...

Embodiment 3

[0142] Example 3 Preparation of fermented ginger kimchi in a 1000kg bag

[0143] A. Pretreatment

[0144] Wash the fresh ginger to remove impurities and set aside;

[0145] B. Disinfection and cleaning

[0146] The ginger pretreated in step A was disinfected with a chlorine dioxide aqueous solution with a mass concentration of 0.20‰ for 4 minutes to control the total number of microorganisms to ≤300CFU / g; rinsed with water for 5 minutes and drained to obtain raw ginger. spare;

[0147] C. Preparation of fermentation solution

[0148] a. Weighing

[0149] Weigh 50% of ginger raw material, 500Kg; prepare 50% of fermentation solution, 500kg;

[0150] Weigh the following materials based on the total weight of 1000Kg:

[0151] Sodium ethylenediaminetetraacetate 0.10g / kg, 100g;

[0152] Potassium sorbate 0.30g / kg, 300g;

[0153] Sodium metabisulfite 0.10g / kg, 100g;

[0154] Sodium dehydroacetate 0.20g / kg, 200g;

[0155] No iodine salt 50.0g / kg, 50Kg;

[0156] Citric acid 5.00g / kg, 5kg;

[0157] Compou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com