Preparation method and equipment with low waste liquid discharge and used for silver-coated copper powder

A waste liquid discharge, silver-coated copper powder technology, applied in metal processing equipment, transportation and packaging, coating, etc., can solve the problems of material waste, low production efficiency, environmental pollution, etc., to reduce copper loss and improve production Efficiency, the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1: Pickling of flake copper powder

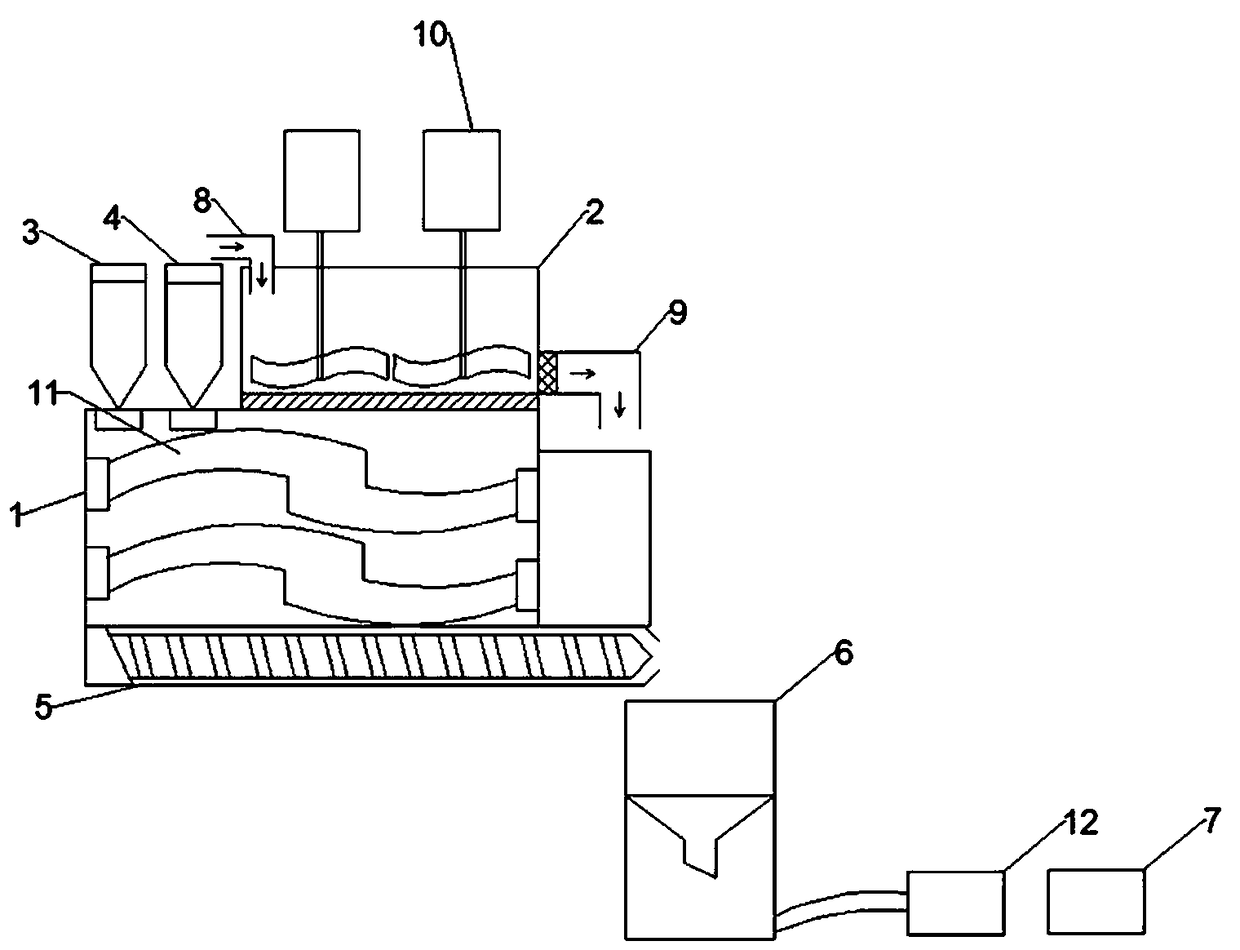

[0025] Add 0.35kg of concentrated sulfuric acid into 150kg of deionized water to form a dilute sulfuric acid solution. The prepared dilute sulfuric acid solution is fed into the pickling tank 2 through the liquid inlet 8 .

[0026] Put 70kg of flaky copper powder into the pickling tank 2, and stir for 20 minutes at a speed of 200-400rmp using a double paddle stirrer 10. Open the discharge port 9 of the pickling pool 2 to discharge the waste acid solution.

[0027] Close the drain port 9, open the liquid inlet port 8, and rinse the residual acid solution on the flake copper powder with deionized water. Then make the deionized water submerge the flake copper powder, stir at a speed of 200-400rmp for 10 minutes, open the drain port 9, and discharge the cleaning wastewater.

[0028] Step 2: Kneading flake copper powder

[0029] Dissolve 47kg of silver nitrate in 40kg of deionized water, add 42kg of ammonia water to make the solu...

Embodiment 2

[0038] Step 1: Pickling of flake copper powder

[0039] Add 0.4kg of concentrated sulfuric acid into 200kg of deionized water to form a dilute sulfuric acid solution. The prepared dilute sulfuric acid solution is fed into the pickling tank 2 through the liquid inlet 8 .

[0040] Put 100kg of flaky copper powder into the pickling tank 2, and stir for 20 minutes at a speed of 200-400rmp using a double paddle agitator 10. Open the discharge port 9 of the pickling pool 2 to discharge the waste acid solution.

[0041] Close the drain port 9, open the liquid inlet port 8, and rinse the residual acid solution on the flake copper powder with deionized water. Then make the deionized water submerge the flake copper powder, stir at a speed of 200-400rmp for 10 minutes, open the drain port 9, and discharge the cleaning wastewater.

[0042] Step 2: Kneading flake copper powder

[0043] Dissolve 79kg of silver nitrate in 75kg of deionized water, add 72kg of ammonia water to make the sol...

Embodiment 3

[0052] Step 1: Pickling of flake copper powder

[0053] Add 0.5kg of concentrated sulfuric acid into 230kg of deionized water to form a dilute sulfuric acid solution. The prepared dilute sulfuric acid solution is fed into the pickling tank 2 through the liquid inlet 8 .

[0054] Put 140kg of flaky copper powder into the pickling tank 2, and stir for 20 minutes at a speed of 200-400rmp using a double paddle agitator 10. Open the discharge port 9 of the pickling pool 2 to discharge the waste acid solution.

[0055] Close the drain port 9, open the liquid inlet port 8, and rinse the residual acid solution on the flake copper powder with deionized water. Then make the deionized water submerge the flake copper powder, stir at a speed of 200-400rmp for 10 minutes, open the drain port 9, and discharge the cleaning wastewater.

[0056] Step 2: Kneading flake copper powder

[0057] Dissolve 95kg of silver nitrate in 90kg of deionized water, add 88kg of ammonia water to make the sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com