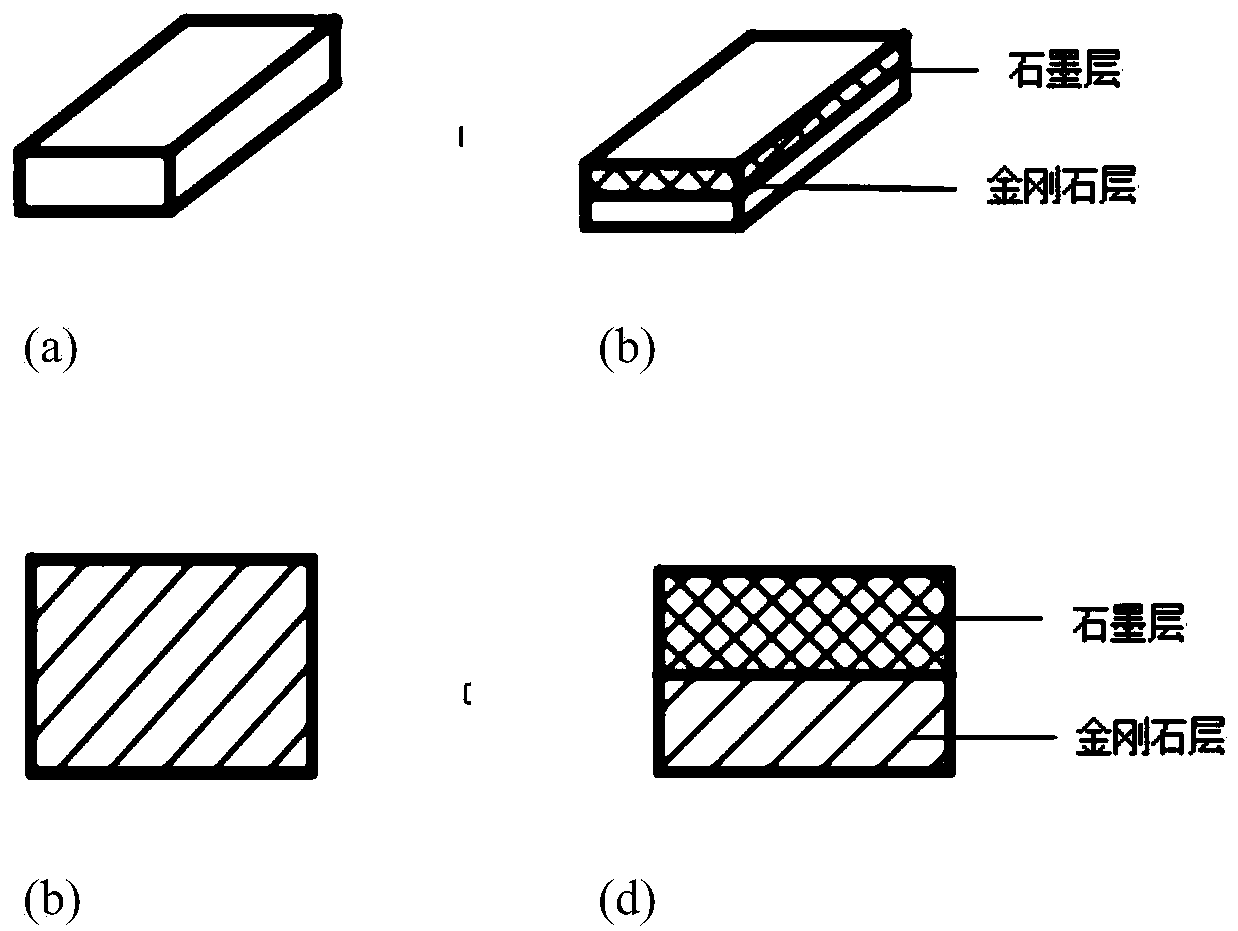

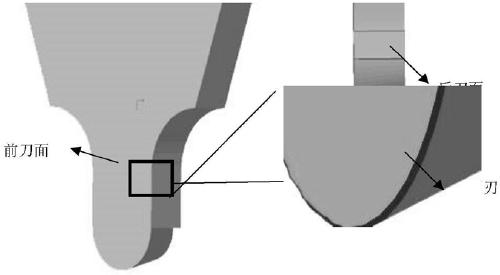

Preparation method of CVD diamond micro-milling cutter

A diamond tool, diamond technology, applied in the direction of diamond, milling cutter, milling machine equipment, etc., to achieve the effect of good precision and micro machining, low grinding resistance, and few cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The laser-induced graphitization-assisted precision grinding method for CVD diamond micro-milling cutters of the present invention will be described below in conjunction with the accompanying drawings and a specific embodiment.

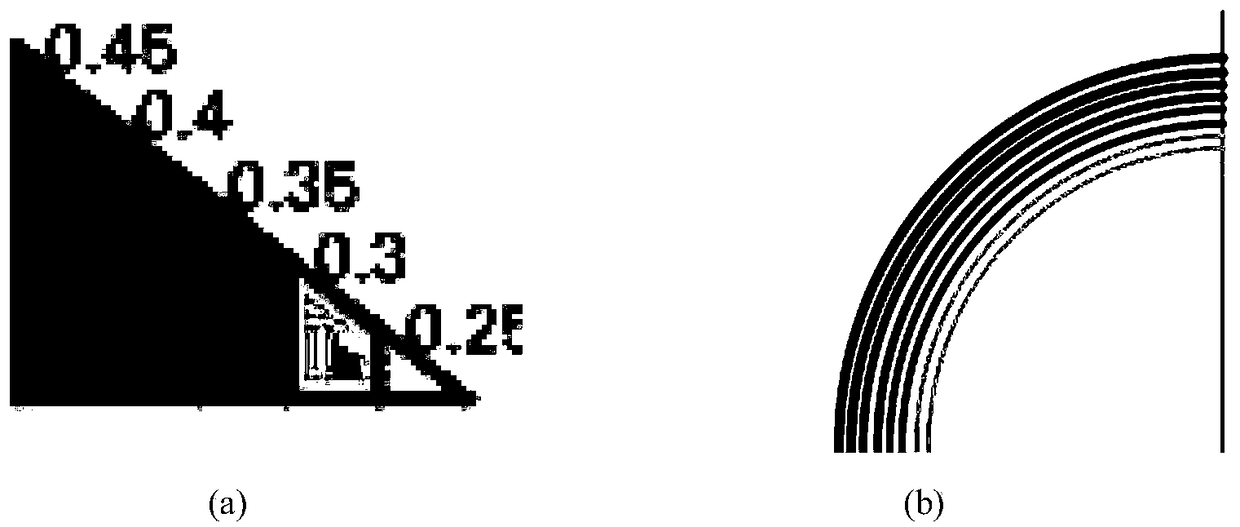

[0019] In order to study the effects of different single pulse energy (e), scanning speed (v) and filling spacing (d) on the graphitization depth of diamond, the following 15 sets of simulations and experiments were carried out. The first 9 groups fixed the laser single pulse energy at 0.25mJ to study the effects of laser scanning speed and filling spacing on the graphitization depth. After that, three groups of variable power simulations with single pulse energy of 0.35mJ and 0.45mJ were carried out respectively. The final simulation results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com