Method for improving dyeing fastness of mat rush

A technology of color fastness and rush, applied in the field of rush for weaving, can solve the problems of poor dyeing rate and color fastness, not obvious, etc., meet the dyeing requirements, improve dyeing efficiency, and improve dyeing rubbing fastness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

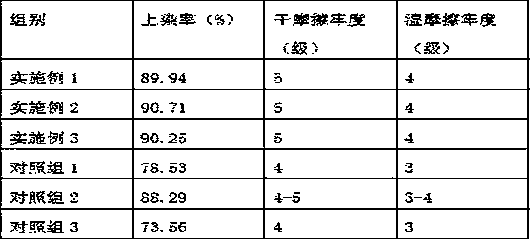

Examples

Embodiment 1

[0018] A method for improving the color fastness of rush for weaving, comprising the following content:

[0019] (1) In parts by weight, mix 25 parts of polyacrylate random copolymer modified polyurethane prepolymer, 18 parts of castor oil, 6.5 parts of boric acid, 2 parts of organometallic carboxylic acid compound, and 400 parts of water at a temperature of 90°C Stir and mix to obtain a mixed solution;

[0020] (2) Wash the collected rush and dry it at a temperature of 35°C until the water content is less than 20%, then immerse it in the mixed solution and treat it for 2 hours under a negative pressure of 0.1MPa. Drying at a temperature of 70°C for 3.5 hours to obtain the treated rush;

[0021] (3) Dye the treated rush under the condition of pH 6.5, the amount of dye is 0.2% of the weight of the rush, the bath ratio of the dyeing process is 1:10, and the addition of dyeing auxiliaries and dyeing auxiliaries is also included Amount is 8% of dyestuff weight, obtains dyeing ma...

Embodiment 2

[0029] A method for improving the color fastness of rush for weaving, comprising the following content:

[0030] (1) In parts by weight, mix 22 parts of polyacrylate random copolymer modified polyurethane prepolymer, 20 parts of castor oil, 5 parts of boric acid, 3 parts of organometallic carboxylic acid compound, and 400 parts of water at a temperature of 85°C Stir and mix to obtain a mixed solution;

[0031] (2) Wash the collected rush and dry it at a temperature of 35°C until the water content is less than 20%, then immerse it in the mixed solution, and treat it for 2.5 hours under the condition of a negative pressure of 0.08MPa. Drying for 3 hours under the condition of 65° C. to obtain the treated rush;

[0032] (3) Dye the treated rush under the condition of pH 6.8, the amount of dye is 0.1% of the weight of the rush, the bath ratio of the dyeing process is 1:10, and the addition of dyeing auxiliaries and dyeing auxiliaries is also included The amount is 10% of the wei...

Embodiment 3

[0040] A method for improving the color fastness of rush for weaving, comprising the following content:

[0041] (1) In parts by weight, mix 28 parts of polyacrylate random copolymer modified polyurethane prepolymer, 16 parts of castor oil, 8 parts of boric acid, 1 part of organometallic carboxylic acid compound, and 400 parts of water at a temperature of 95°C Stir and mix to obtain a mixed solution;

[0042] (2) Wash the collected rush and dry it at a temperature of 35°C until the water content is less than 20%, then immerse it in the mixed solution, and treat it for 1.5 hours under the condition of a negative pressure of 0.12MPa. Drying for 4 hours at a temperature of 75°C to obtain the treated rush;

[0043] (3) Dye the treated rush under the condition of pH 6.2, the amount of dye is 0.3% of the weight of the rush, the bath ratio of the dyeing process is 1:10, and the addition of dyeing auxiliaries and dyeing auxiliaries is also included Amount is 6% of dyestuff weight, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com