A vacuum nested high-efficiency cold-resistant structural material

A structural material and vacuum technology, applied in the direction of synthetic resin layered products, transportation and packaging, coating, etc., to achieve the effect of isolating heat transfer and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

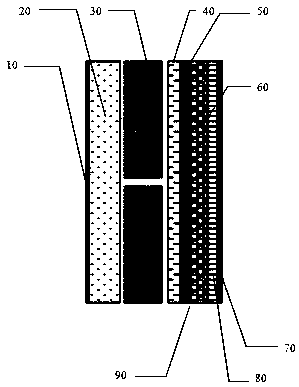

[0022] refer to figure 1 , is a vacuum nested high-efficiency cold-resistant structural material, which is composed of a cold-resistant layer 20, an insulating material 30 and an interior decoration layer 90, and is characterized in that the cold-resistant layer 20 is made of cold-resistant long glass fiber reinforced cold-resistant resin material The cold-resistant long glass fiber is swollen with n-heptane solution, and then the treated cold-resistant long glass fiber is immersed in the toughening solution, washed by ultrasonic vibration, and dried in an oven. The cold-resistant resin material is made of polyolefin elastomer and three It is obtained by modifying polypropylene resin with ethylene-propylene rubber particles; the outer surface of the cold-resistant layer 20 is coated with a layer of high cold-resistant coating 10, and the components of the high cold-resistant coating 10 include low-hydroxy polyurethane acrylic resin, cellulose acetate butyrate Resin, pearl powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com