High-silicon Y zeolite and preparation method thereof

A zeolite and high-silicon technology, applied in the directions of crystalline aluminosilicate zeolite, fajhedral crystalline aluminosilicate zeolite, etc., can solve the problems of harsh preparation conditions of the guiding agent, and achieve easy filtration and recovery, high surface energy, and improved catalysis. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 2.34g of sodium metaaluminate into a beaker, add 31.5mL of distilled water, stir until the sodium metaaluminate is completely dissolved, add 5.86g of sodium hydroxide, continue stirring until the solution is clear and cool to room temperature, add 22.5mL of water under vigorous stirring Glass, stir for about 15 minutes to make the mixture uniform, move the beaker to a 30°C water bath, stir and age for 16 hours to make a directing agent. The molar ratio of each component in the directing agent is 13Na 2 O:Al 2 o 3 : 15SiO 2 : 320H 2 O.

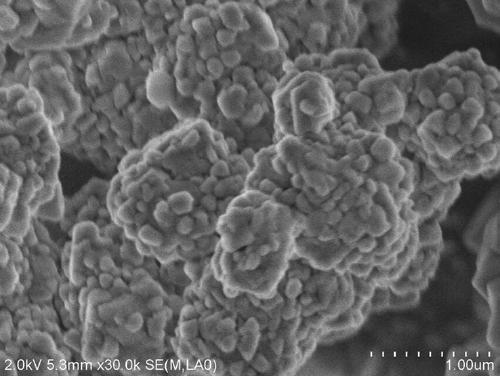

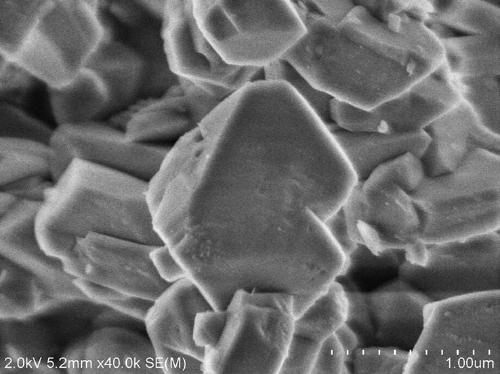

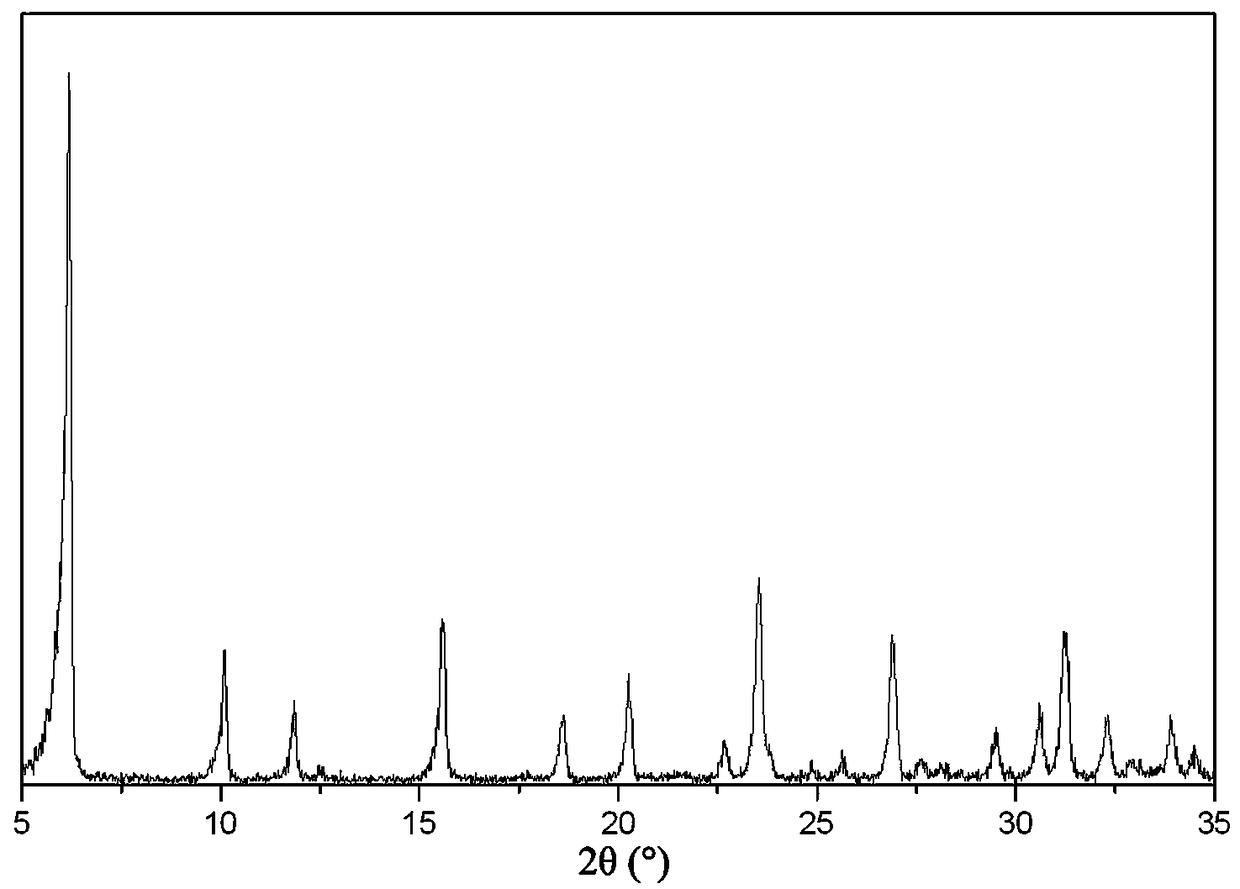

[0037] Add 37.0mL of distilled water into the beaker, weigh 1.20g of sodium metaaluminate and 5.0g of sodium hydroxide into the distilled water, stir evenly to form a clear solution, slowly add 31.0mL of water glass under stirring, stir evenly, and obtain a ratio of 24.5Na 2 O: 40SiO 2 :Al 2 o 3 : 783H 2 O gel mixture. After continuous stirring for 2h, add 3.0g SiO 2 / Al 2 o 3 5.0 industrial NaY zeolite and 3.0 mL of d...

Embodiment 2

[0044] Weigh 2.34g of sodium metaaluminate into a beaker, add 49.5mL of distilled water, stir until the sodium metaaluminate is completely dissolved, add 3.19g of sodium hydroxide, continue stirring until the solution is clear and cool to room temperature, add 18.0mL of water under vigorous stirring glass, stir for about 15 minutes to make the mixture uniform, move the beaker to a 25°C water bath, stir and age for 16 hours, and make a directing agent. The molar ratio of each component in the directing agent is 8.7Na 2 O:Al 2 o 3 : 12SiO2 2 : 400H 2 O.

[0045] Add 36.0mL of distilled water into the beaker, weigh 1.20g of sodium metaaluminate and 7.11g of sodium hydroxide into the distilled water, stir evenly to form a clear solution, slowly add 35.0mL of water glass under stirring, stir evenly, and obtain a ratio of 19.8Na 2 O: 40SiO 2 :Al 2 o 3 :800H 2 O gel mixture. After continuous stirring for 2h, add 6.0g SiO 2 / Al 2 o 3 5.0 industrial NaY zeolite and 5.5mL o...

Embodiment 3

[0053] Weigh 2.34g of sodium metaaluminate into a beaker, add 40.5mL of distilled water, stir until the sodium metaaluminate is completely dissolved, add 6.80g of sodium hydroxide, continue stirring until the solution is clear and cool to room temperature, add 27.0mL of water under vigorous stirring Glass, stir for about 15 minutes to make the mixture uniform, move the beaker to a 30°C water bath, stir and age for 12 hours, and make a directing agent. The molar ratio of each component in the directing agent is 15Na 2 O:Al 2 o 3 : 18SiO 2 : 400H 2 O.

[0054] Add 40.0mL of distilled water into the beaker, weigh 1.20g of sodium metaaluminate and 7.11g of sodium hydroxide into the distilled water, stir evenly to form a clear solution, slowly add 31.0mL of water glass under stirring, stir evenly, and obtain a ratio of 30Na 2 O: 40SiO 2 : Al 2 o 3 :800H 2 O gel mixture. After continuous stirring for 2h, add 6.0g SiO 2 / Al 2 o 3 10.0 industrial NaY zeolite and 4.0 mL of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com