3D decorative glass and preparation method thereof

A decorative glass, 3D technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of difficulty in controlling the film thickness and effect of printed curved surfaces, affecting the accuracy of patterns, and deteriorating decorative effects, etc. problem, to achieve the effect of easy laser engraving, good decorative effect, and smooth edges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

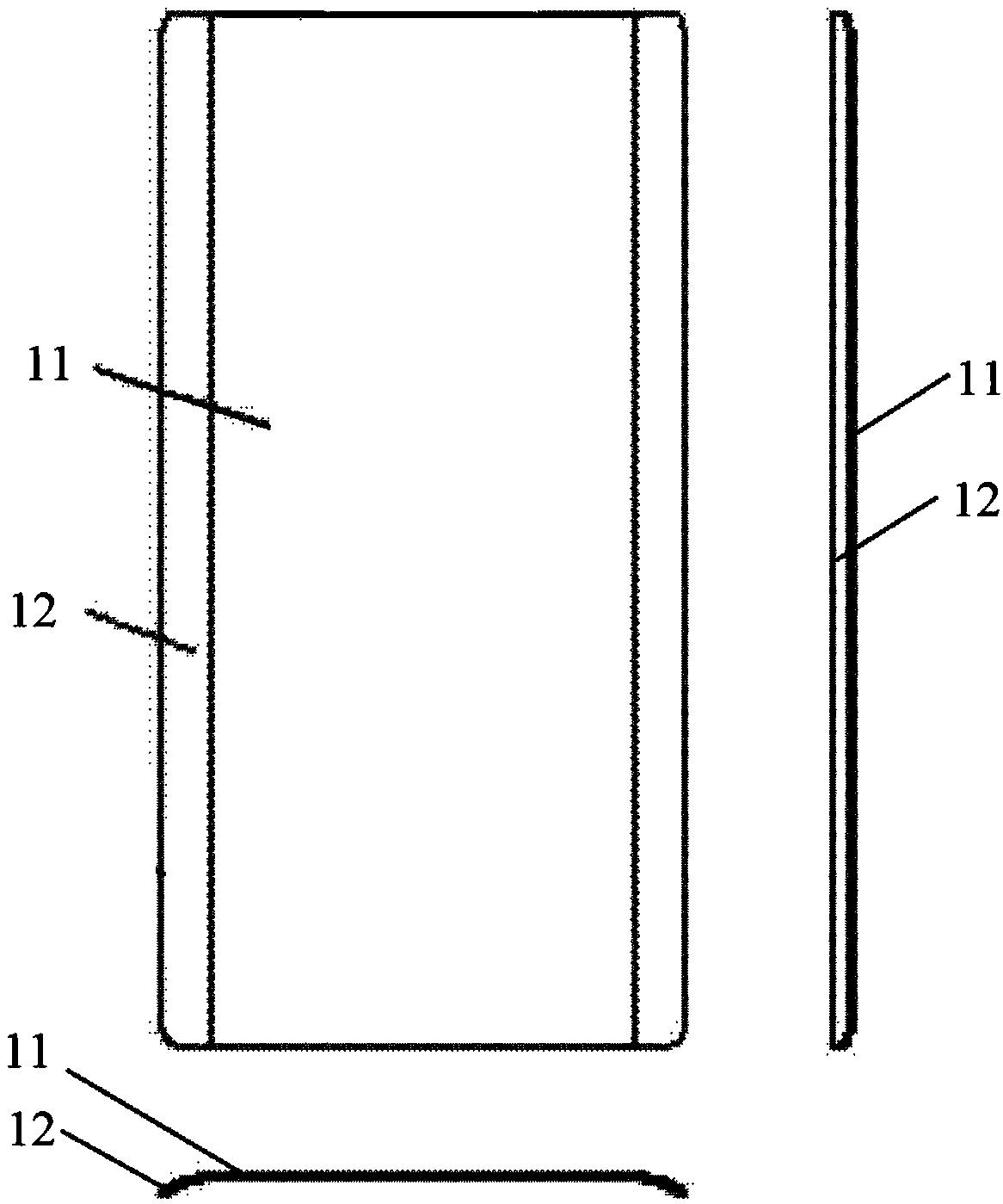

[0043] At the same time, the present invention also provides a method for preparing a 3D decorative glass, the method comprising the following steps: S1, preparing a light-absorbing ink, and spraying it on one side surface of the 3D glass substrate, drying and curing to form a light-absorbing ink layer; S2. Inject laser light from the other side of the 3D glass substrate, etch the light-absorbing ink layer to form a partially hollowed-out decorative ink layer; S3. On the surface of the one side of the 3D glass substrate, fill the part of the decorative ink layer A metal mirror filling layer is formed in the hollow area; S4, forming a black light-shielding ink layer on the surface of the decorative ink layer and the metal mirror filling layer away from the 3D glass substrate.

[0044] The steps of the above-mentioned method provided by the present invention are simple and easy to reproduce, and the laser is used to etch the light-absorbing ink layer attached to the other side of...

Embodiment 1 to 4 and comparative example 1

[0058] (1) The ink composition used to form the light-absorbing ink layer: the manufacturers, models and related physical properties of the raw materials used are as follows, and the ratio of raw materials is shown in Table 1:

[0059] Saturated polyester resin: SIPKYD 8208 resin from Xipu Chemical Co., Ltd., with a Tg of 67°C;

[0060] Amino resin: MR-625 from Lihuaxin Company, methyl etherified melamine formaldehyde resin;

[0061] Carbon black: Evonik's FW-200, the blackness value My is 296, and the particle size distribution is 5-15nm;

[0062] Precipitated silica: OK607 from Degussa Company, oil absorption is 220g / 100g, particle size D90 is 6μm;

[0063] Dispersant: BYK-2000 from BYK, Germany;

[0064] Silane coupling agent: Dow Corning's Z-6040, epoxy silane coupling agent;

[0065] Leveling agent: Tego 600 from Tego, Germany;

[0066] Defoamer: Tego 900 from Dego, Germany;

[0067] Table 1.

[0068]

Example 1

Example 2

Example 3

Example 4 ...

Embodiment 5

[0078] (1) The ink composition that is used to form light-absorbing ink layer: with embodiment 1;

[0079] (2) The preparation method of 3D decorative glass: with reference to Example 1, the difference is:

[0080] S3. Take the SZ-6301 primer purchased from Guangdong Shenzhan Industrial Co., Ltd. as a transparent vacuum coating primer, and adjust the viscosity of the primer to 8.5s under the condition of 25°C in Iwata 2# cup; then apply it on 3D glass On the one side surface of the substrate, spray the aforementioned mirror-surface silver ink in the hollow area of the decorative ink layer, then dry and solidify (ultraviolet intensity is 1200mj / cm 2 ) to form a transparent ink filling layer (thickness is 3 μm) filled in the hollow area of the decorative ink layer, and then place the aforementioned treated 3D glass in a vacuum coating machine so that the 3D glass is formed with a transparent ink filling layer One side is exposed, metal indium is used as the electroplating r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com