Ardealite supersulfated cement and preparation method thereof

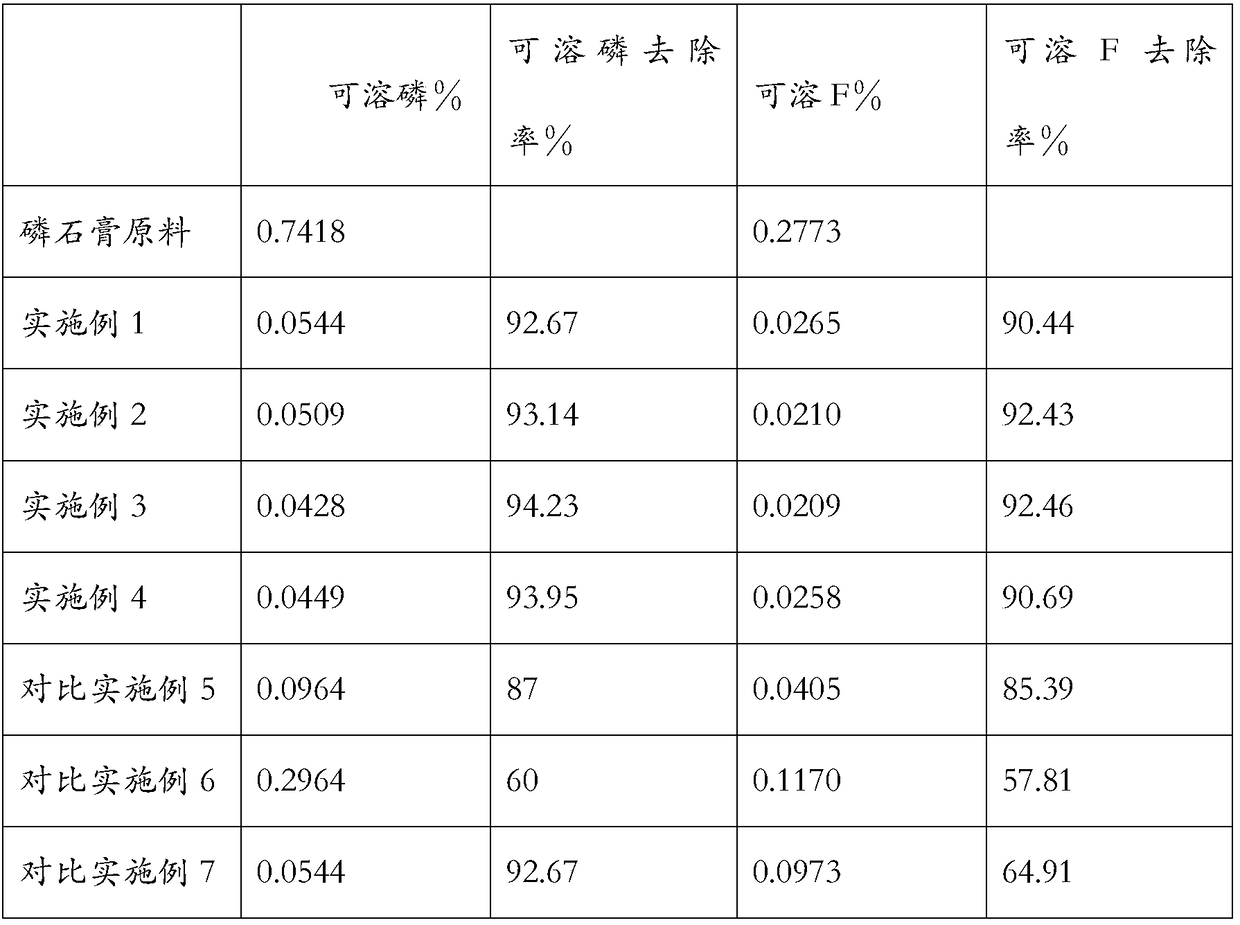

A technology of supersulfate cement and phosphogypsum is applied in the field of building materials, which can solve the problems of soluble phosphorus pollution and low removal rate of soluble phosphorus, and achieve the effect of improving the flexural and compressive strength and the removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

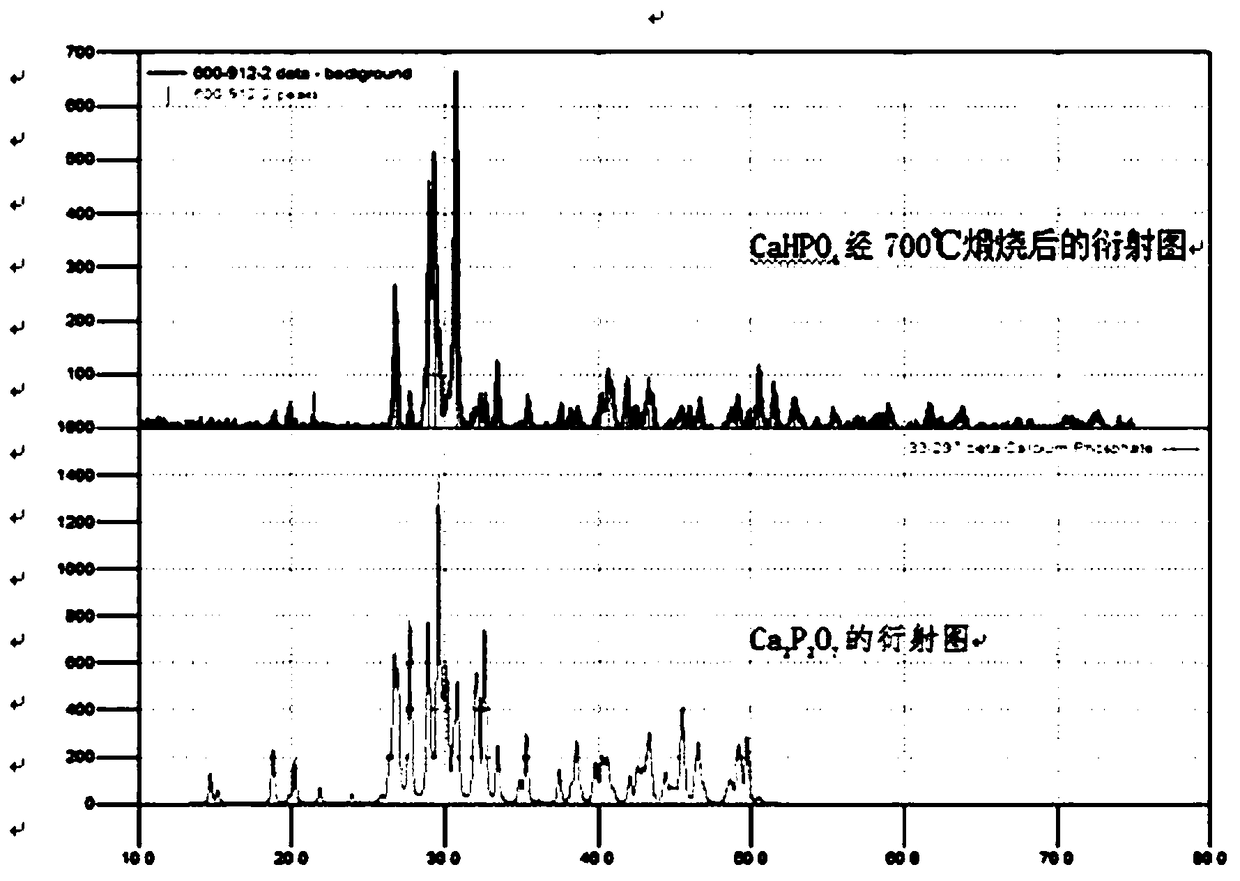

Image

Examples

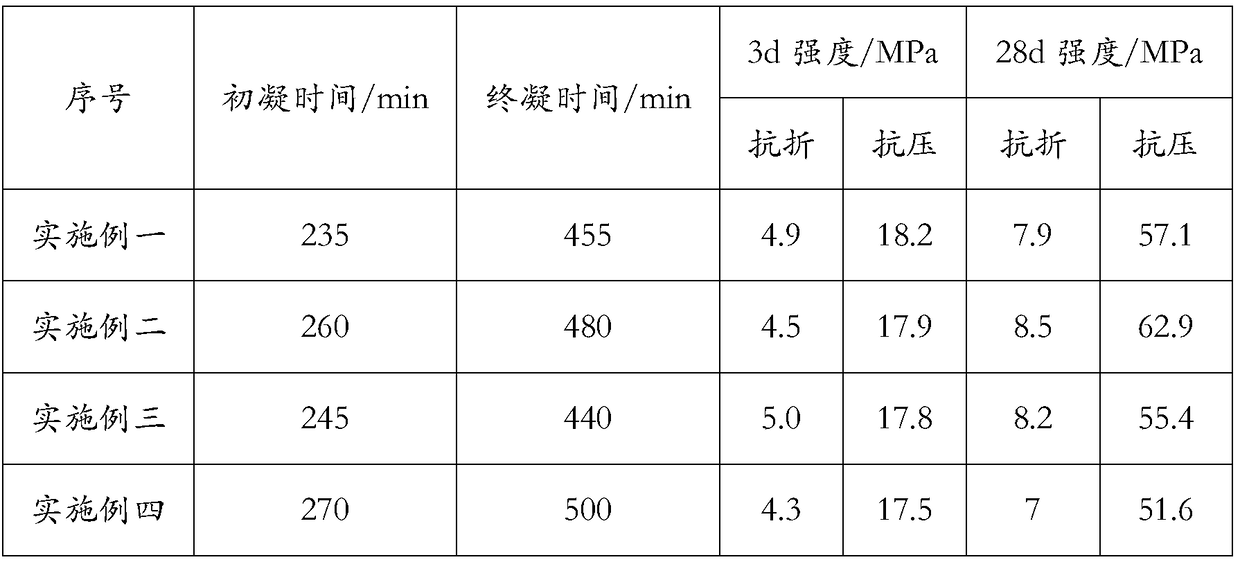

Embodiment 1

[0019] First, modify the phosphogypsum: neutralize the phosphogypsum with calcium oxide to neutral and age for 24 hours, calcinate the neutralized phosphogypsum at 660°C for 1 hour, and grind it after cooling. The specific surface area is 430m 2 / kg. By weight, take 80 parts of slag micropowder, 11.5 parts of modified phosphogypsum, 3 parts of calcium carbonate, 5 parts of Portland cement, and 0.5 part of lithium carbonate, and put them into the mixer for 30 minutes and 58 rpm / min to obtain 100 parts of phosphogypsum super sulfate cement.

Embodiment 2

[0021] First, modify the phosphogypsum: neutralize the phosphogypsum with calcium hydroxide to neutral and age for 24 hours, calcinate the neutralized phosphogypsum at 700°C for 0.8 hours, and grind it after cooling. The specific surface area after grinding is 450m 2 / kg. By weight, take 70 parts of slag fine powder, 18 parts of modified phosphogypsum, 3.9 parts of metakaolin, 6 parts of Portland cement, 2 parts of high alumina cement, and 0.1 part of lithium hydroxide, and put them into the mixer. For 25 minutes, the stirring speed was 60 rpm to obtain 100 parts of phosphogypsum super sulfate cement.

Embodiment 3

[0023] First, modify the phosphogypsum: neutralize the phosphogypsum with calcium hydroxide to neutral and age for 24 hours, calcinate the neutralized phosphogypsum at 730°C for 0.8h, and grind it after cooling. The specific surface area after grinding is 470m 2 / kg. By weight, take 65.8 parts of slag micropowder, 25 parts of modified phosphogypsum, 8 parts of Portland cement, 1 part of calcium hydroxide, and 0.2 part of sodium aluminate, and put them into a mixer, stirring for 35 minutes, and the stirring speed 62 rev / min, obtain 100 parts of phosphogypsum super sulfate cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com