A preparation method of an alloy target forming ohmic contact on the surface of n-type gallium arsenide

An ohmic contact, alloy target technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve the problems of poor processing performance, unfavorable high-performance thin film, high alloy brittleness, etc., to achieve good plasticity, increase The effect of nucleation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

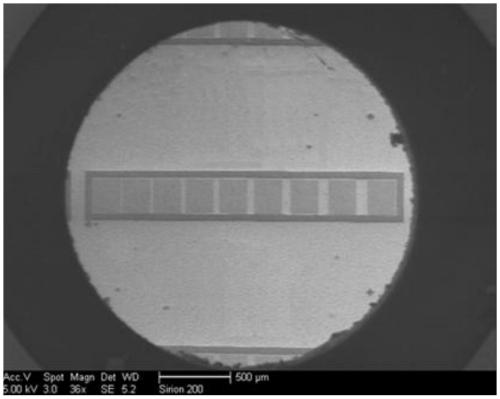

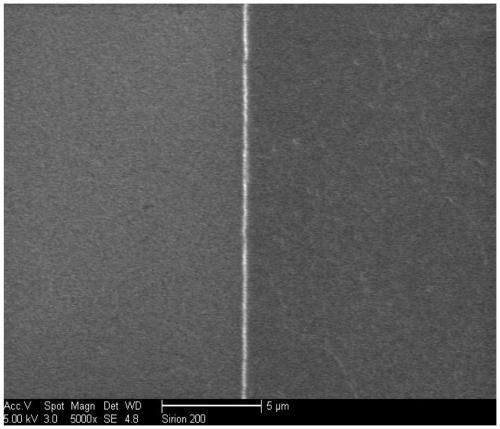

Image

Examples

Embodiment 1

[0022] The target material is mixed with 2 wt% gold and 98 wt% indium, and the preparation method includes the following steps:

[0023] 1) Use a vacuum induction melting furnace to melt metal indium (in a vacuum induction melting furnace with a vacuum degree of 8 Pa, heat the indium raw material to 200 ° C, and keep it warm for 30 minutes after the indium metal is completely melted), and then gold nano The powder (10-100nm) is mixed into the metal indium in the molten state and stirred evenly;

[0024] 2) When the melt is stirred, keep warm and degas for 15 minutes;

[0025] 3) Pour the indium-gold mixture into the casting mold at a temperature of 180°C, and cool it to room temperature (15-30°C) to form an indium-gold alloy ingot with eutectic composition or hypoeutectic composition;

[0026] 4) The ingot is subjected to hot pressing and rolling (45°C, the deformation rate of the hot rolling pass is 3%), and the internal pores and grain boundaries are removed;

[0027] 5) U...

Embodiment 2

[0031] The target material is mixed with 8 wt% gold and 92 wt% indium, and the preparation method includes the following steps:

[0032] 1) Use a vacuum induction melting furnace to melt metal indium (in a vacuum induction melting furnace with a vacuum degree of 12Pa, heat the indium raw material to 220°C, and keep it warm for 40 minutes after the indium metal is completely melted), and then gold nano powder Mixed into the metal indium in the molten state and stirred evenly;

[0033] 2) When the melt is stirred, keep warm and degas for 20 minutes;

[0034] 3) Pour the indium-gold mixture into the casting mold at a temperature of 220°C, and cool to room temperature to form an indium-gold alloy ingot with eutectic composition or hypoeutectic composition;

[0035] 4) The ingot is subjected to hot pressing and rolling (55°C, the deformation rate of the hot rolling pass is 8%), and the internal pores and grain boundaries are removed;

[0036] 5) Use a heating furnace to homogeniz...

Embodiment 3

[0040] The target material is mixed with 5 wt% gold and 95 wt% indium, and the preparation method includes the following steps:

[0041] 1) Use a vacuum induction melting furnace to melt metal indium (in a vacuum induction melting furnace with a vacuum degree of 10 Pa, heat the indium raw material to 210 ° C, and keep it warm for 32 minutes after the indium metal is completely melted), and then gold nano The powder is mixed into the metal indium in the molten state and stirred evenly;

[0042] 2) When the melt is stirred, keep warm and degas for 18 minutes;

[0043] 3) Pour the indium-gold mixture into the casting mold at a temperature of 200°C, and cool it to room temperature to form an indium-gold alloy ingot with eutectic composition or hypoeutectic composition;

[0044] 4) The ingot is subjected to hot pressing and rolling (50°C, the deformation rate of the hot rolling pass is 5%), and the internal pores and grain boundaries are removed;

[0045] 5) Use a heating furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com