Paint painting construction method for wall decoration

A construction method and wall decoration technology, applied in the direction of architecture, building structure, etc., to achieve the effect of good painting quality, stain resistance and excellent formaldehyde absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

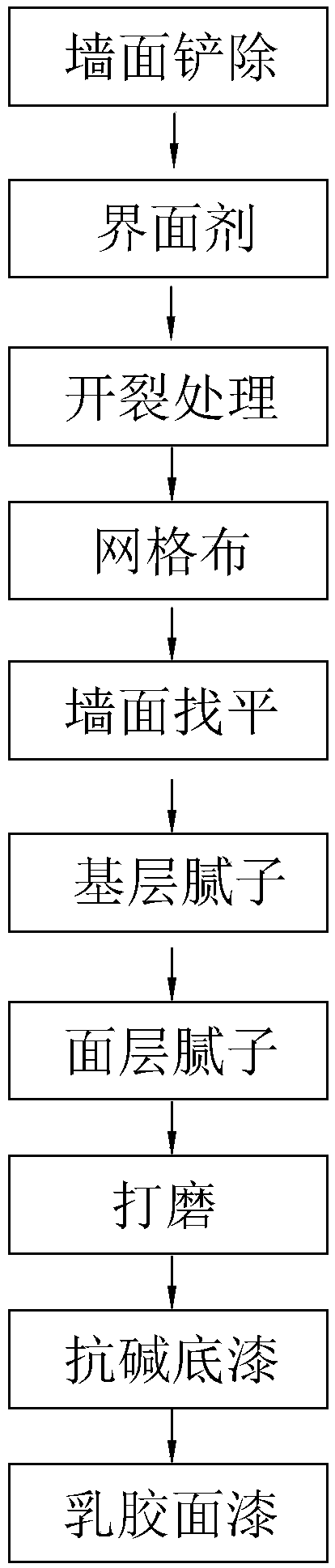

[0045] A method for painting a paint for wall decoration, comprising the steps of:

[0046] Step 1: Remove all the original wall paint layer, and then paint the interface agent on the wall;

[0047] Step 2: Paste white glue stickers on the cracks on the wall, then lay grid cloth on the entire wall, and then brush cement mortar until the wall is flat;

[0048] Step 3: First apply a layer of putty on the base layer, then brush the putty on the surface layer twice, and then polish;

[0049] Step 4: First apply a layer of anti-alkali primer, and then apply two coats of latex topcoat.

Embodiment 2

[0051] Latex finish paint comprises the component of following weight part among the embodiment one:

[0052] 55 parts of styrene-acrylic emulsion;

[0053] 0.4 parts of hydroxyethyl cellulose;

[0054] 1.2 parts of defoamer;

[0055] 1.2 parts of organic bentonite;

[0056] 85 parts of deionized water;

[0057] 0.35 parts of dispersant;

[0058] 36 parts of mica powder;

[0059] 14 parts of diatomaceous earth;

[0060] 13 parts of montmorillonite powder;

[0061] 0.8 part of polysiloxane;

[0062] 5.5 parts of anatase titanium dioxide;

[0063] Lithopone 11 parts;

[0064] 2 parts of nano silicon dioxide, the particle size is 100nm;

[0065] 2 parts of nano-titanium dioxide, the particle size of which is 35nm;

[0066] 3 parts of silane coupling agent;

[0067] 10 parts of silicone emulsion;

[0069] Negative ion powder 7 parts.

[0070] The model of defoamer is ZW-1406, purchased from Guangzhou Zhongwan New Material Co., Ltd.; the ...

Embodiment 3

[0076] Latex finish paint comprises the component of following weight part among the embodiment one:

[0077] 60 parts of styrene-acrylic emulsion;

[0078] 0.6 parts of hydroxyethyl cellulose;

[0079] 1.5 parts of defoamer;

[0080] 1.5 parts of organic bentonite;

[0081] 90 parts of deionized water;

[0082] 0.4 parts of dispersant;

[0083] 42 parts of mica powder;

[0084] 16 parts of diatomaceous earth;

[0085] 16 parts of montmorillonite powder;

[0086] 1 part polysiloxane;

[0087] 6 parts of anatase titanium dioxide;

[0088] Lithopone 12 parts;

[0089] 3 parts of nano silicon dioxide, the particle size is 120nm;

[0090] 3 parts of nano-titanium dioxide, the particle size of which is 50nm;

[0091] 5 parts of silane coupling agent;

[0092] 12 parts of silicone emulsion;

[0093] 3 parts of plant powder;

[0094] Negative ion powder 8 parts.

[0095] The model of defoamer is ZW-1406, purchased from Guangzhou Zhongwan New Material Co., Ltd.; the mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com