Single composite impeller gas turbine engine

A compound impeller and gas turbine technology, applied in the direction of gas turbine devices, liquid fuel engines, engine components, etc., can solve the problems of difficult control of rotor rotation accuracy and vibration stability, reduce turbine life, engine performance, and affect development and application. The effect of rotor mechanical rotation performance, weight reduction and structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

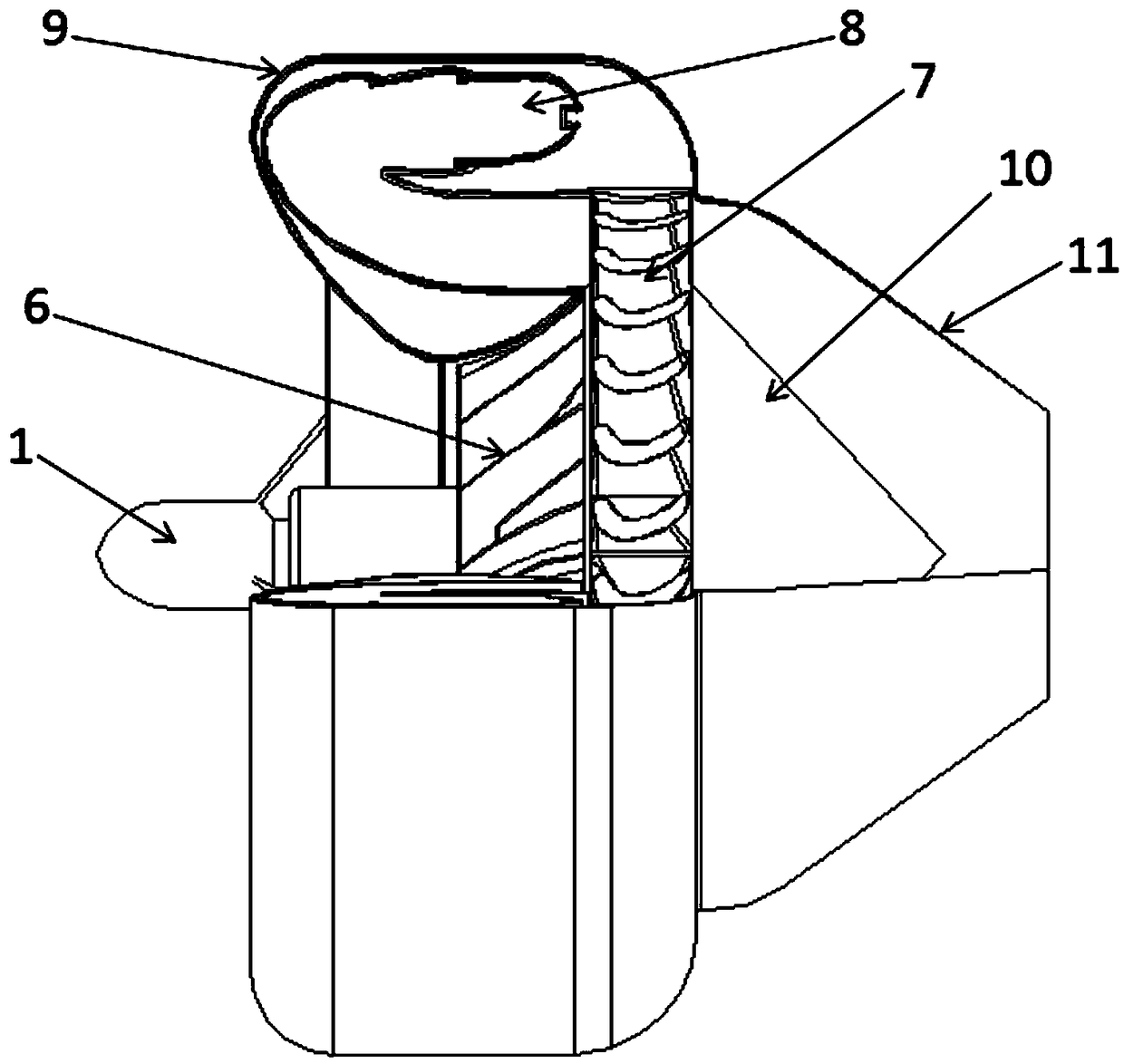

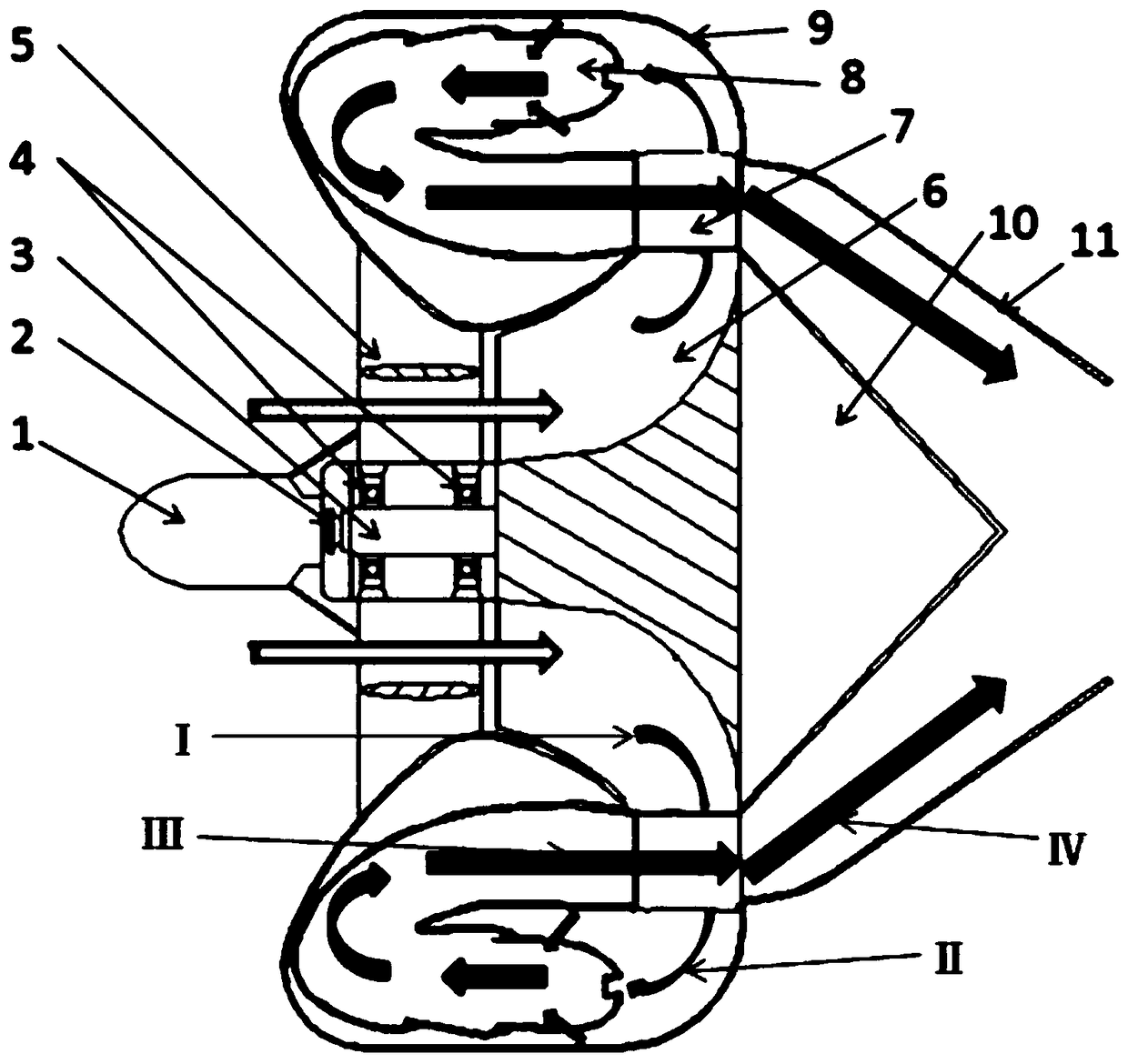

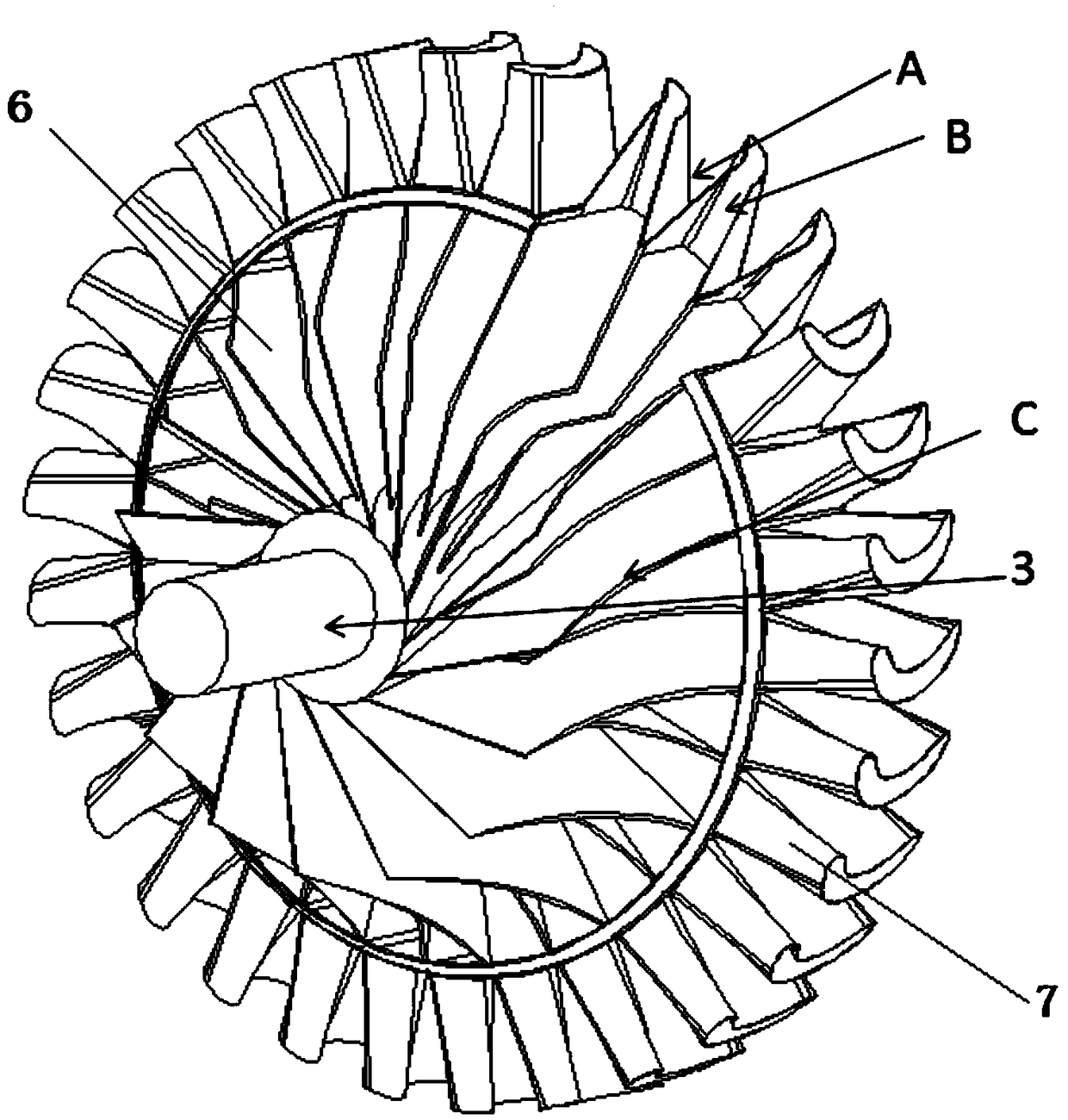

[0011] Please refer to figure 1 , 2 , shown in 3, a kind of gas turbine engine of single compound impeller, comprises starter motor (1), clutch (2), main shaft (3), bearing (4), rectifying bracket (5), centrifugal compressor blade (6) , hollow turbine blade (7), annular swirling combustor (8), annular casing assembly (9), tail cone (10), tail nozzle (11), outer edge of centrifugal compressor blade (6) The radial channels and hollow turbine blades (7) are smoothly connected to form a composite impeller with dual functions of compressing air and expanding work. The starter motor (1) is connected to one end of the main shaft (3) through the clutch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com