Variable-hole-diameter porous ceramic burning plate

A technology of porous ceramics and combustion plates, applied to burners, burners, combustion methods, etc., can solve the problems of many flames leaving the surface of the combustion plate, low conversion rate of infrared rays, and low temperature of the combustion plate, so as to improve combustion stability and Effects of flame speed, widening combustion limit range, and reducing emission concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

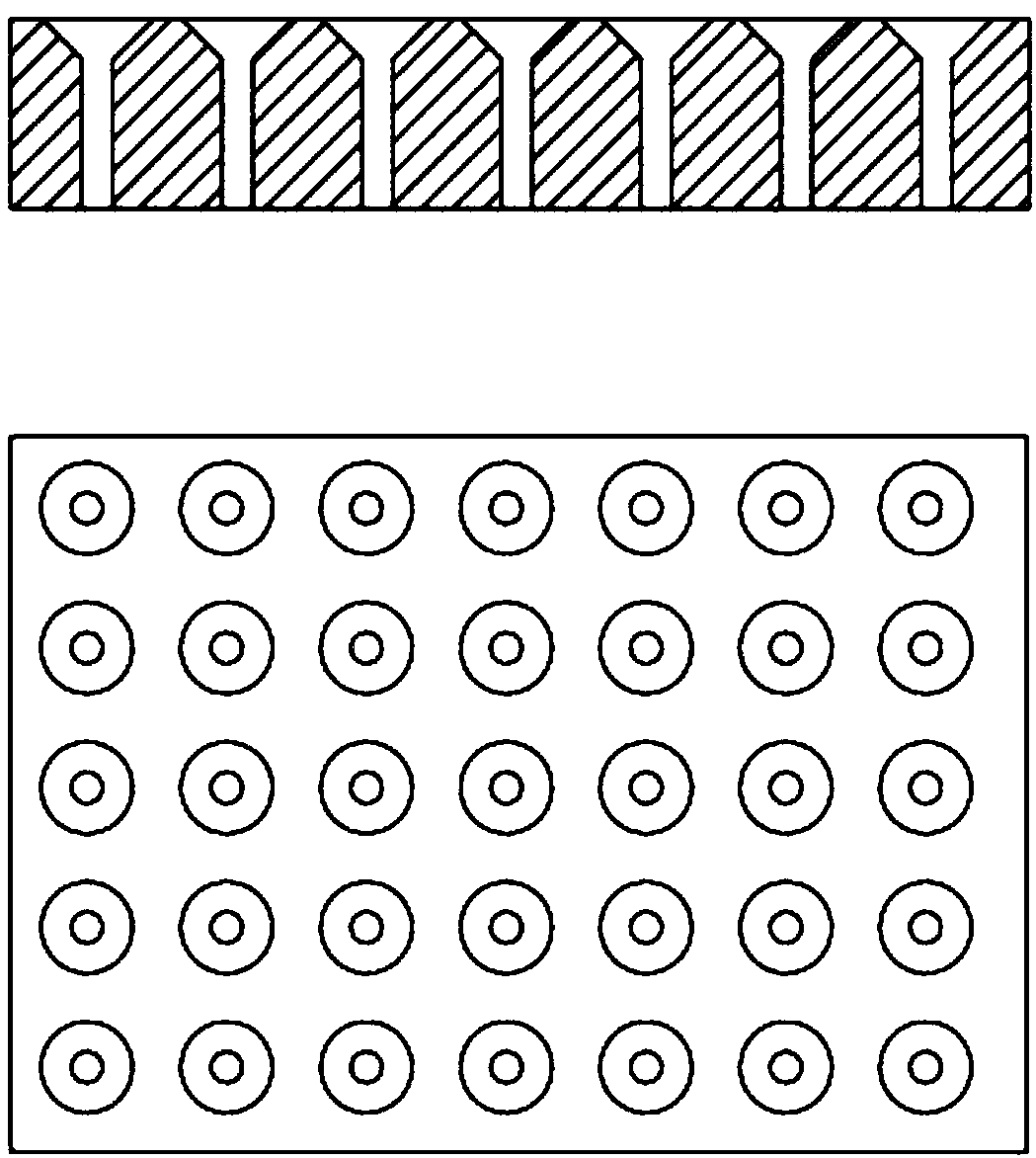

[0010] Embodiment one: figure 1 The ceramic combustion plate is composed of dense circular through holes, the diameter of the air inlet surface is about 1mm, and after keeping the diameter of the hole at a depth of 8mm, it begins to expand symmetrically in a V shape at an angle of 90°, to a diameter of about 1.6mm, and the minimum hole spacing is about 2.0mm , uniformly densely distributed. This combustion board is suitable for liquefied petroleum gas and natural gas, but not for coke oven gas and water gas.

[0011] Refer to the quenching distance of various gases as follows:

[0012] At room temperature (20°C)

[0013] Type of gas

[0014] Effect of temperature on quenching distance (natural gas)

[0015] Fire hole surface temperature

[0016] Since the intake air temperature is generally low, even if the mixture has been preheated, it is generally recommended not to exceed 300 °C, otherwise cold flame combustion may occur. At this time, the inlet ape...

Embodiment 2

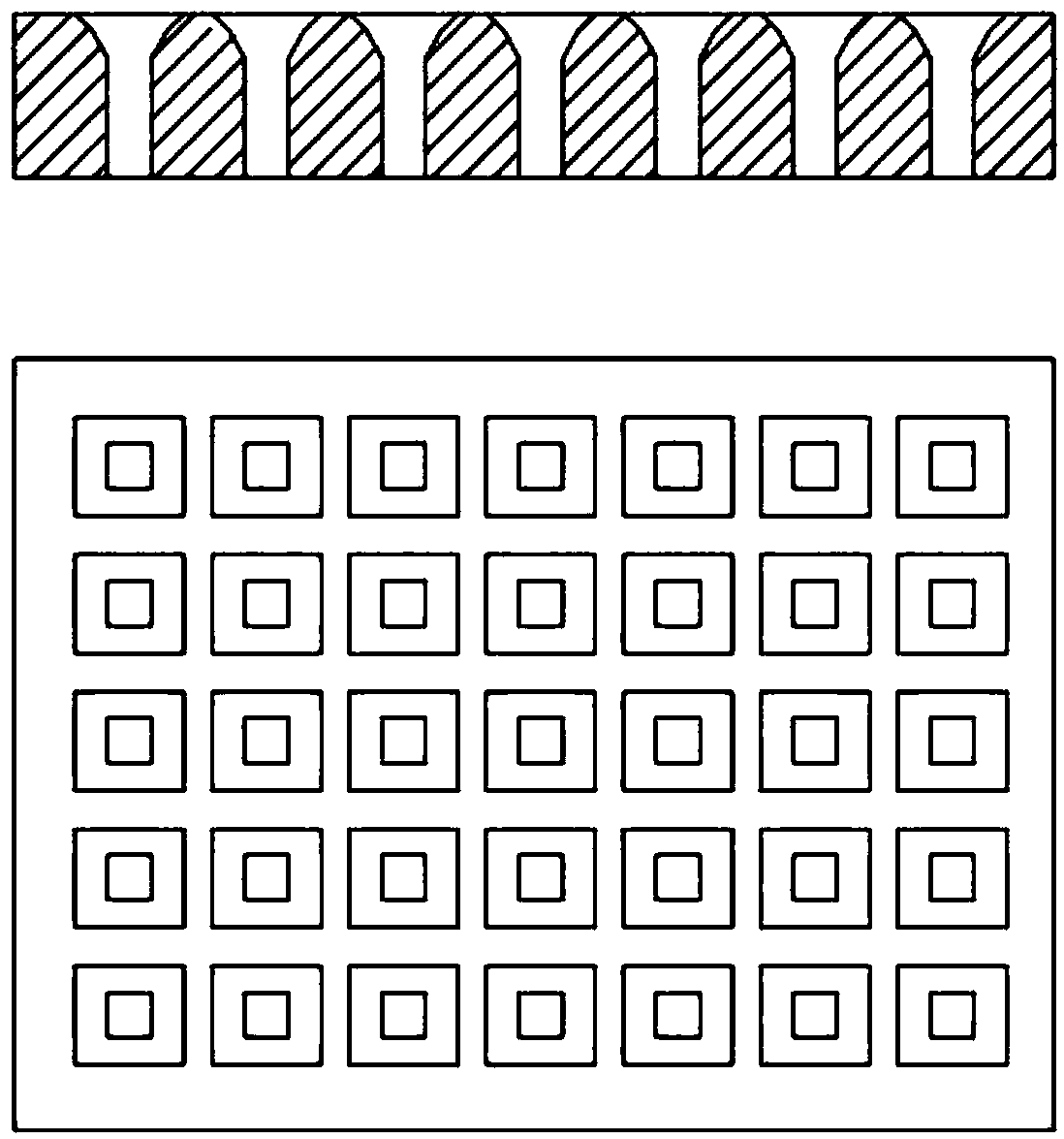

[0017] Embodiment two: figure 2 The ceramic combustion plate is composed of dense square through holes. The side length of the air intake surface is about 1*1mm, and the diameter of the hole is maintained at a depth of 8mm. The distance is about 2.0mm, evenly and densely distributed, and the catalyst composed of cerium oxide is evenly coated on the surface of the inner hole enlarged by the arc. This combustion board is suitable for liquefied petroleum gas and natural gas, but not for coke oven gas and water gas.

[0018] The combustion heating principle of this scheme is basically similar to scheme 1, the difference is that since the enlarged surface of the circular arc is coated with a catalyst, the combustion process can be made faster and the infrared conversion efficiency is higher, of course, the cost will also be higher.

[0019] The advantage of this scheme is that the porosity of the combustion plate is high, the air flow rate is large, and it has a catalytic effect,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com