Wavefront sensor based on modified Hartmann mask and detection method

A wavefront sensor and an improved technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of limiting the application scenarios of random coded hybrid gratings, low processing yield, etc., to improve measurement accuracy, reduce processing difficulty, high Effect of Diffraction Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the content, implementation process and advantages of the present invention clearer, the present invention will be further described below in conjunction with embodiment and accompanying drawing, but do not limit protection scope of the present invention with this embodiment. The numbers in the following brackets correspond to the numbers in the accompanying drawings of the specification.

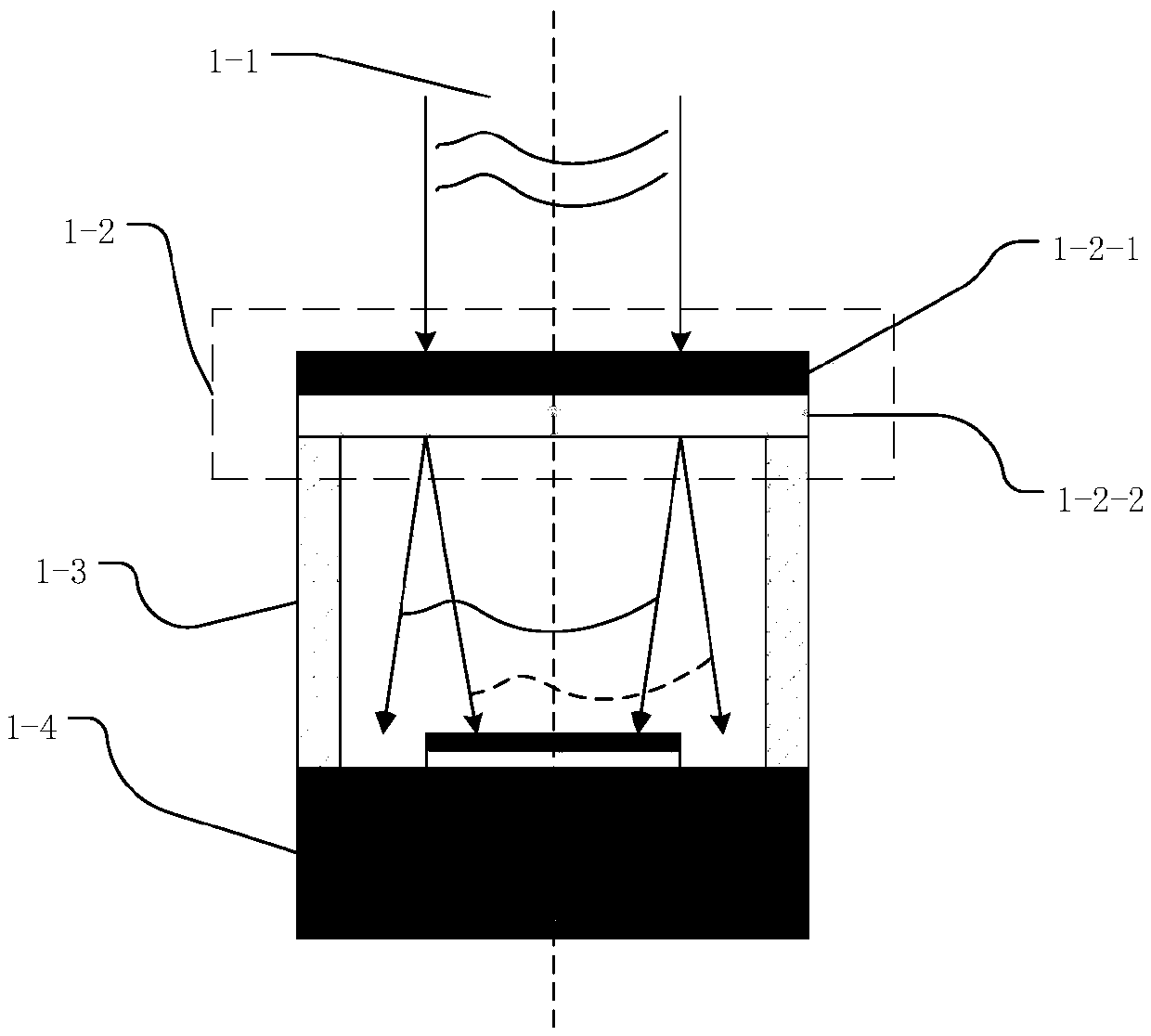

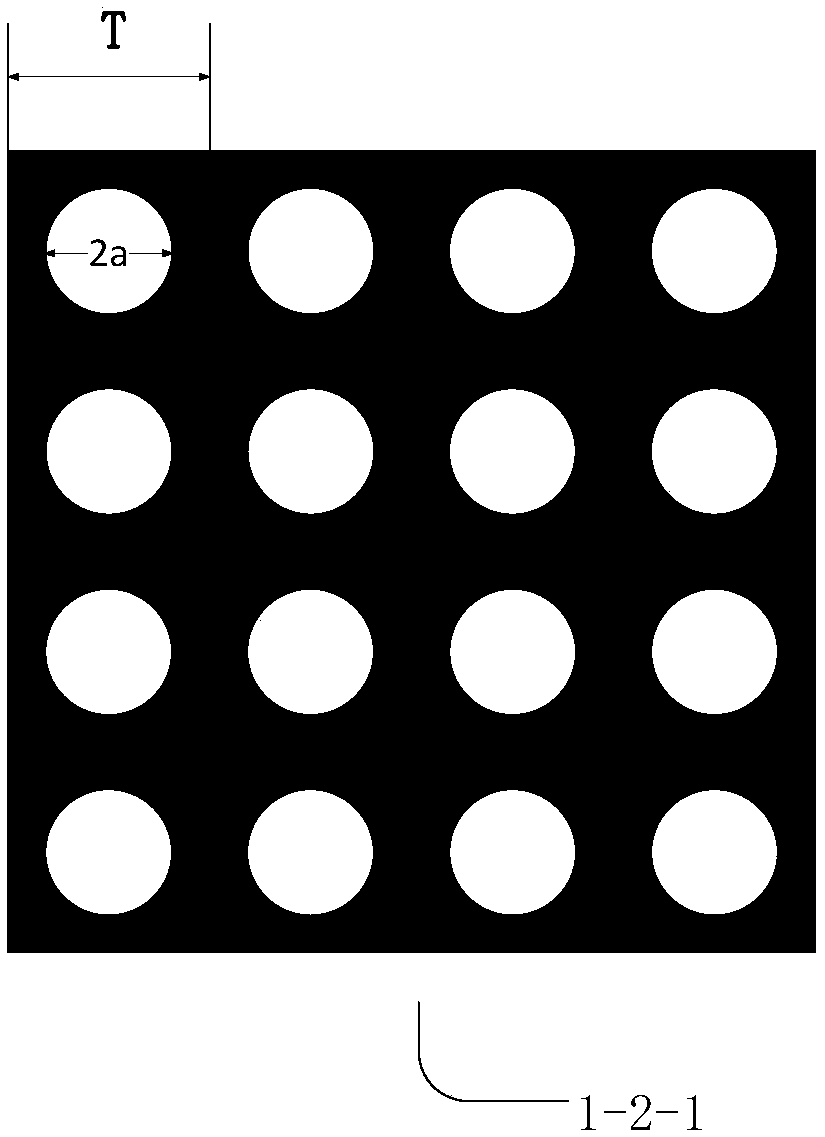

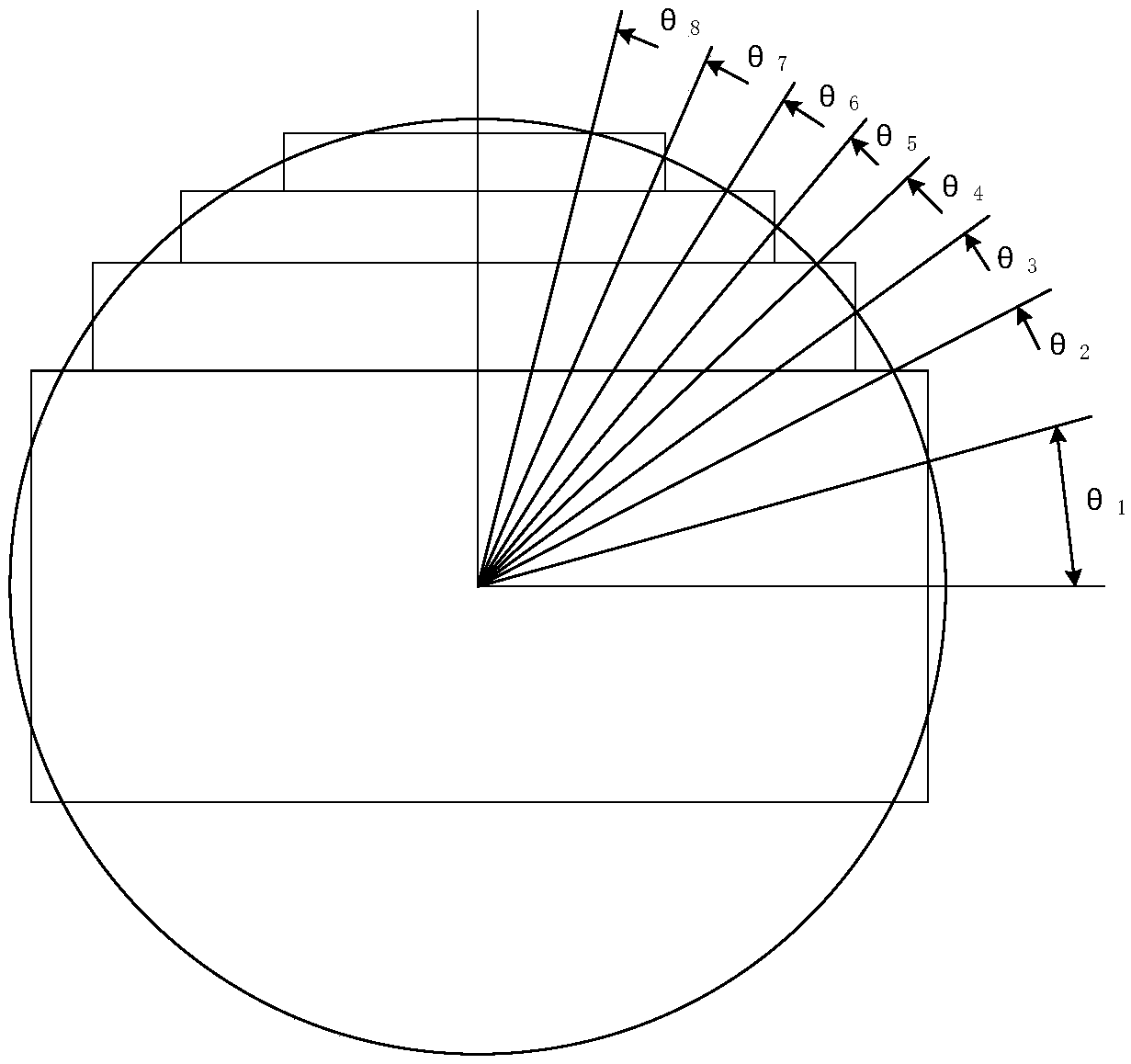

[0037] A wavefront sensor based on an improved Hartmann mask, including a diffractive optical element 1-2 and a two-dimensional photodetector 1-4, the diffractive optical element is a two-dimensional grating with the same period in the orthogonal direction The structure is composed of an amplitude grating 1-2-1 with a period of T and an approximately circular light-transmitting region and a checkerboard phase grating 1-2-2 with a period of 2T and a phase gradient of π at the central wavelength; The positional relationship between the diffractive optical element and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com