Plastic mold comprehensive detection device and detection method

A plastic mold and comprehensive detection technology, which is applied in the direction of circuit breaker testing, by measuring the rate of increase and deceleration of fluid, and using liquid/vacuum degree for liquid tightness measurement, etc. It can solve the problems of large error in test results, low labor efficiency, Solve problems such as heavy labor burden, achieve the effect of improving factory efficiency, reducing testing costs, and liberating manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing and embodiment:

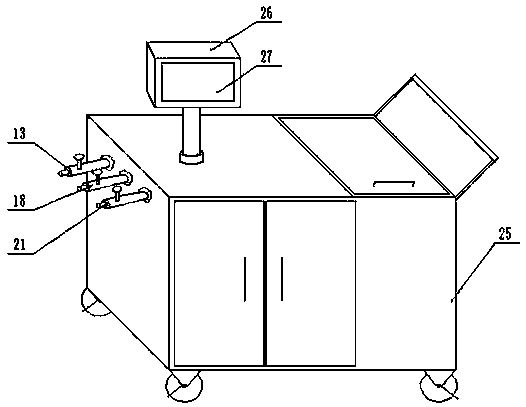

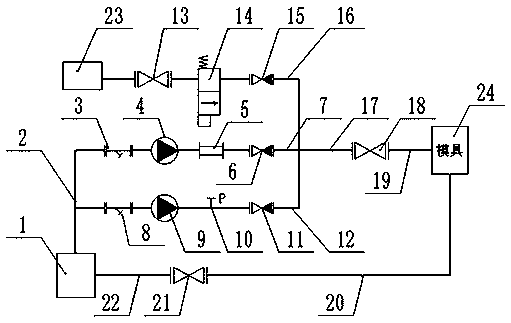

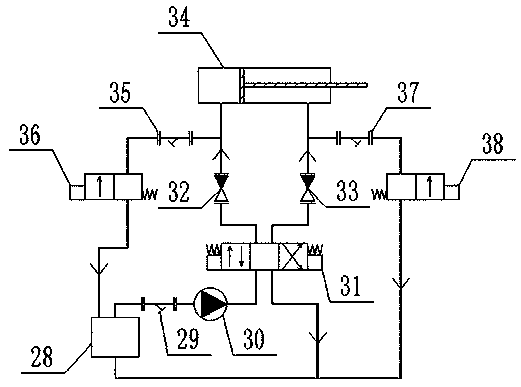

[0046] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention discloses that the plastic mold comprehensive testing equipment includes a cooling system testing system and an ejection mechanism testing system, and the cooling system testing system includes a pressure testing system, a flow testing system and an air blowing cleaning system. Such as figure 1 and figure 2 As shown, the cooling system testing system includes a movable box 25, the inside of the box 25 is provided with a water tank 1, and the inside of the water tank 1 is provided with two layers of filters, the first layer of filters is filter cotton, which can filter Larger particles; the second layer of filtration is a magnet, which is used to absorb impurities such as iron filings from the mould, and the return water of the water tank 1 returns to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com