Manufacturing method of diode having ladder type structure

A manufacturing method, ladder-shaped technology, applied in the field of diodes, can solve problems such as glass damage, high grain glass height, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

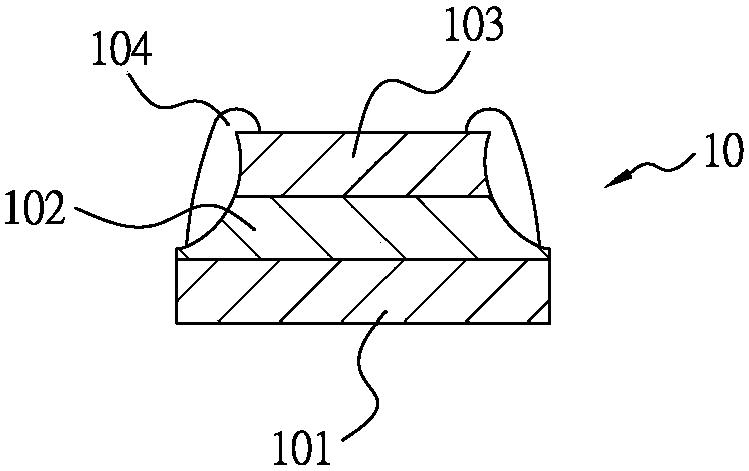

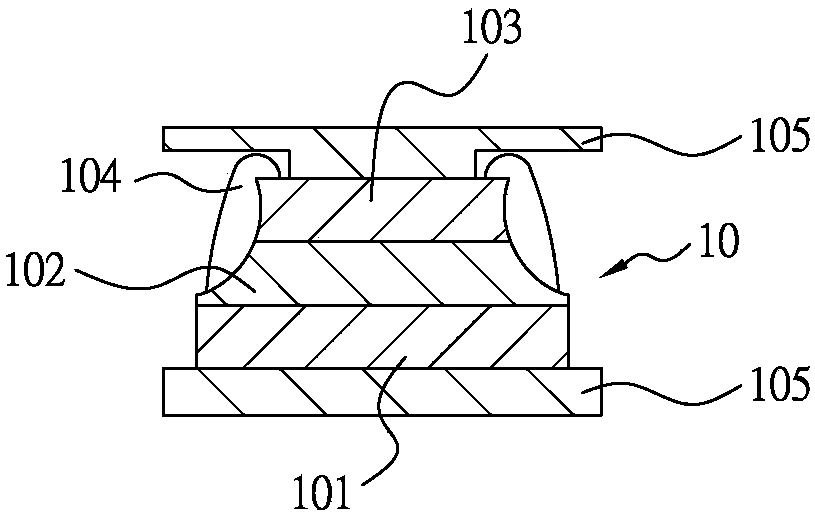

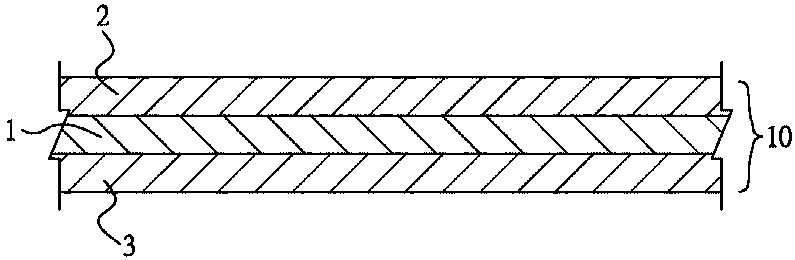

[0027] see Figure 3 to Figure 6 As shown, it is a schematic diagram of the manufacturing process structure of the present invention. like image 3 As shown, the diode die structure of the present invention mainly includes an N-type semiconductor layer 1. In this embodiment, the N-type semiconductor layer 1 is an N-type crystal (N-type wafer), and the N-type semiconductor layer 1 is stacked on one side. A P-type semiconductor layer 2, an N+-type semiconductor layer 3 is attached to the other side of the N-type semiconductor layer 1, the P-type semiconductor layer 2 and the N+-type semiconductor layer 3 are made of boron paper and phosphorous paper respectively in the process It is attached to both sides of the N-type semiconductor layer 1, and then the P-type semiconductor layer 2 and the N+-type semiconductor layer 3 are respectively formed after a burn-off process, a pre-deposition process, a soaking and separation process, a wet oxidation process and a diffusion process. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com