Solar cell and preparation method thereof, battery piece based on solar cell and photovoltaic module

A technology of solar cells and photovoltaic modules, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of sliced battery power output attenuation, single battery unit, device performance attenuation, etc., to avoid edge leakage and short circuit, and avoid performance attenuation , to avoid the attenuation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of solar cell provided by the invention, its process is as follows:

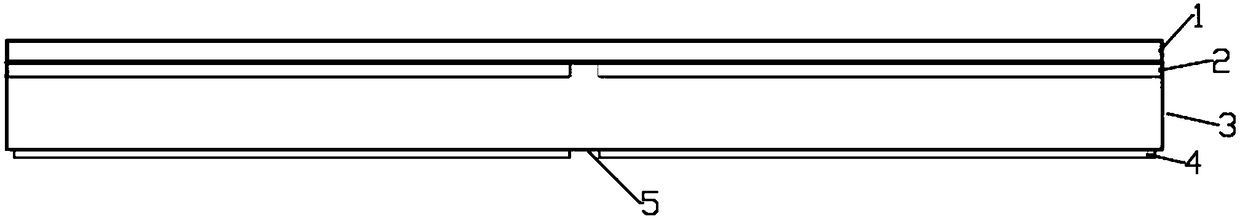

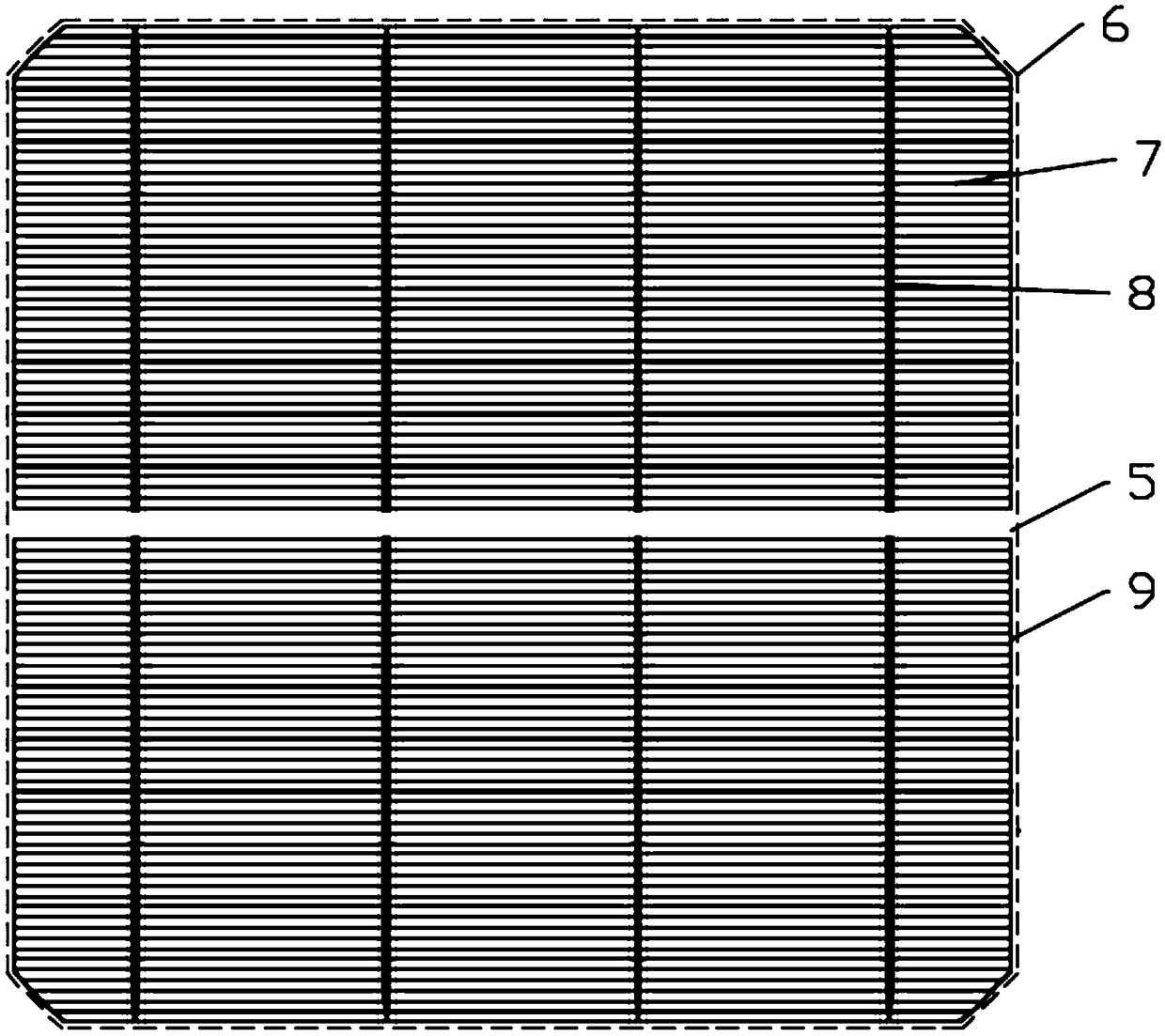

[0060] Prepare several independent emitters 2 on one surface of the silicon substrate 3 with a textured light-trapping structure, and there is a preset distance between the edges of adjacent emitters 2;

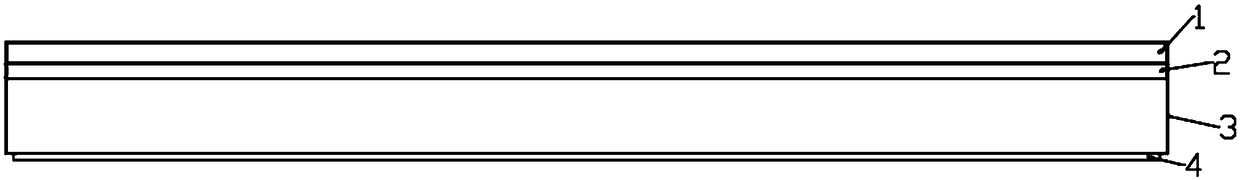

[0061] Prepare a passivation layer 1 on the surface of the silicon substrate prepared with the emitter 2;

[0062] Prepare the electrode pattern again, when preparing the electrode pattern, prepare an independent front electrode pattern on the surface of the passivation layer 1 corresponding to each emitter 2; on the other surface of the silicon substrate 3, correspond to each emitter 2 area to prepare independent back electrode patterns.

[0063] As a preferred embodiment of the present invention, the silicon substrate 3 forms a textured light-trapping structure by chemical etching.

[0064] As a preferred embodiment of the present invention, the electrode pattern is prepare...

Embodiment 1

[0071] The process of preparing solar cells in this embodiment is as follows:

[0072] (1) Texturing: Put the P-type monocrystalline silicon wafer of M2 size in potassium hydroxide alkali solution for anisotropic etching to form a pyramidal light-trapping structure;

[0073] (2) Diffusion: the P-type monocrystalline silicon wafer after texturing is placed in a tubular diffusion furnace and heated in POCl 3 High-temperature diffusion in a gas atmosphere, after the diffusion is completed, a complete pn junction will be formed;

[0074] (3) Etching: Coat the surface of the diffused P-type single crystal silicon wafer with a layer of paraffin, and leave a blank area with a width of about 4 mm in the middle of the P-type single crystal silicon wafer without paraffin. The single crystal silicon wafer is etched in a chain cleaning tank to remove the side junction and back junction formed during the diffusion process and the pn junction in the paraffin-free area on the surface;

[0...

Embodiment 2

[0079] The process of preparing solar cells in this embodiment is as follows:

[0080] (1) Texturing: Put the P-type monocrystalline silicon wafer of M2 size in sodium hydroxide alkali solution for anisotropic etching to form a pyramidal light-trapping structure;

[0081] (2) Diffusion: the P-type monocrystalline silicon wafer after texturing is placed in a tubular diffusion furnace and heated in POCl 3 High-temperature diffusion in a gas atmosphere, after the diffusion is completed, a complete pn junction will be formed;

[0082] (3) Etching: Coat the surface of the diffused P-type single crystal silicon wafer with a layer of paraffin, and leave a blank area with a width of about 4 mm in the middle of the P-type single crystal silicon wafer without paraffin. The single crystal silicon wafer is etched in a chain cleaning tank to remove the side junction and back junction formed during the diffusion process and the pn junction in the paraffin-free area on the surface;

[0083...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com