Silicon-carbon negative electrode, preparation method thereof, lithium ion battery and electric vehicle

A silicon carbon and negative electrode technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor electrical conductivity, large volume effect and serious problems, and achieve the effect of improving heat dissipation capacity, good heat dissipation capacity and improving cycle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] According to a second aspect of the present invention, a method for preparing the above-mentioned silicon-carbon negative electrode is provided, comprising the following steps:

[0067] First coat the coating slurry on the negative electrode current collector, and then coat the silicon carbon negative electrode material slurry after drying to obtain the silicon carbon negative electrode; the coating slurry is mainly bonded by the mass ratio of mesophase pitch, graphene and coating agent is dissolved or dispersed in a solvent; the silicon carbon negative electrode material slurry is mainly obtained by dissolving or dispersing a silicon carbon negative electrode active material, a conductive agent and a negative electrode material binder in a solvent.

[0068] The description of the mesophase pitch, graphene and coating binder of the coating slurry and the description of the silicon carbon negative electrode active material, conductive agent and negative electrode material...

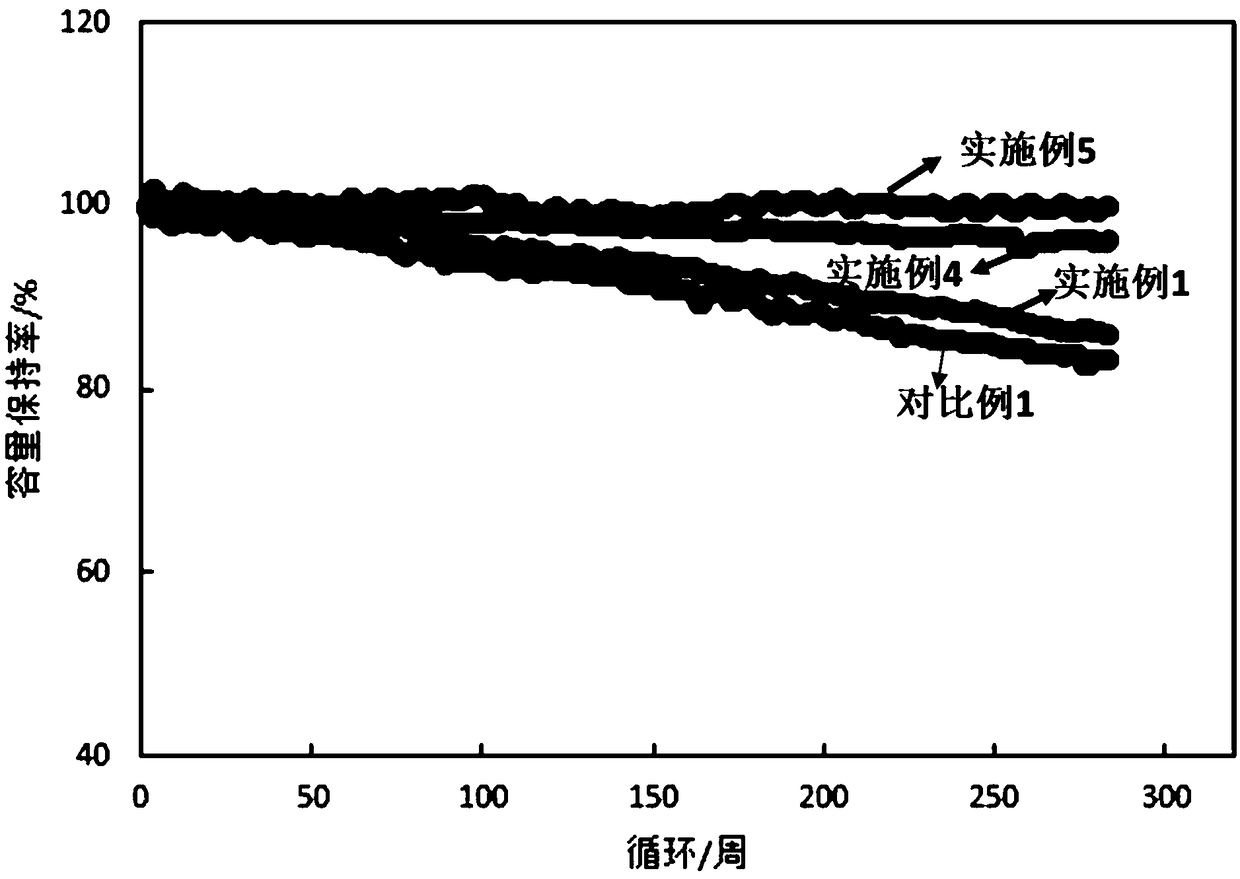

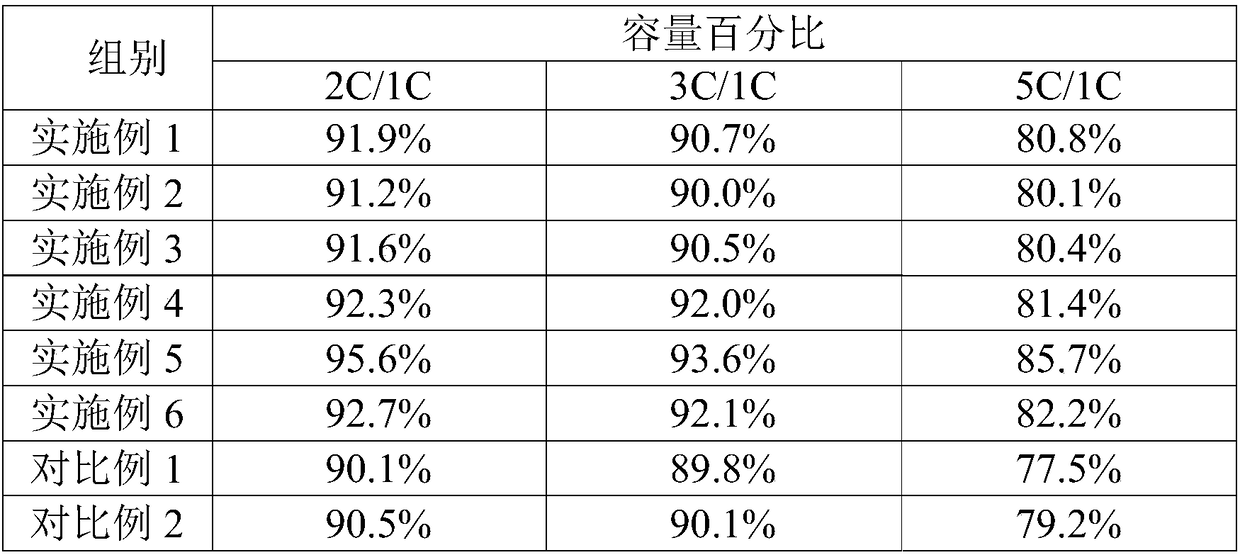

Embodiment 1

[0086] A silicon carbon negative electrode, comprising a negative electrode current collector copper foil and a coating and a silicon carbon negative electrode material layer sequentially arranged on the surface of the negative electrode current collector copper foil;

[0087] The coating is composed of mesophase pitch, graphene and water-based polyvinylidene fluoride with a mass ratio of 30:65:5; the silicon-carbon negative electrode material layer is composed of silicon-carbon negative electrode active materials with a mass ratio of 95.4:1.1:3.5, conductive agent and The negative electrode material is composed of a binder. The silicon carbon negative electrode active material is made of SiO and graphite, and the SiO mass accounts for 8%. The conductive agent is conductive carbon black (SP), and the negative electrode material binder is a mass ratio of 4:3. Sodium carboxymethylcellulose and styrene-butadiene rubber.

[0088] The preparation method of the above-mentioned silic...

Embodiment 2

[0092] A silicon carbon negative electrode, comprising a negative electrode current collector copper foil and a coating and a silicon carbon negative electrode material layer sequentially arranged on the surface of the negative electrode current collector copper foil;

[0093]The coating is composed of mesophase pitch, graphene and water-based polyvinylidene fluoride with a mass ratio of 40:55:5; the silicon-carbon negative electrode material layer is composed of silicon-carbon negative electrode active materials with a mass ratio of 95.4:1.1:3.5, conductive agent and Negative electrode material binder composition, silicon carbon negative electrode active material is made of SiO and graphite composite, SiO mass accounts for 8%, conductive agent is conductive carbon black (SP), negative electrode material binder is 3:4 mass ratio Sodium carboxymethylcellulose and styrene-butadiene rubber.

[0094] The preparation method of the above-mentioned silicon carbon negative electrode c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com