Double-ended output linear cavity all-fiber laser oscillator

A laser oscillator, double-end output technology, applied in lasers, laser parts, phonon exciters, etc., can solve the problem that lasers are difficult to withstand high-power output, cannot use high-power fiber combiners, and limit pump laser injection. Power and other issues, to achieve the effect of reducing power density, ensuring stability, and stable and reliable transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

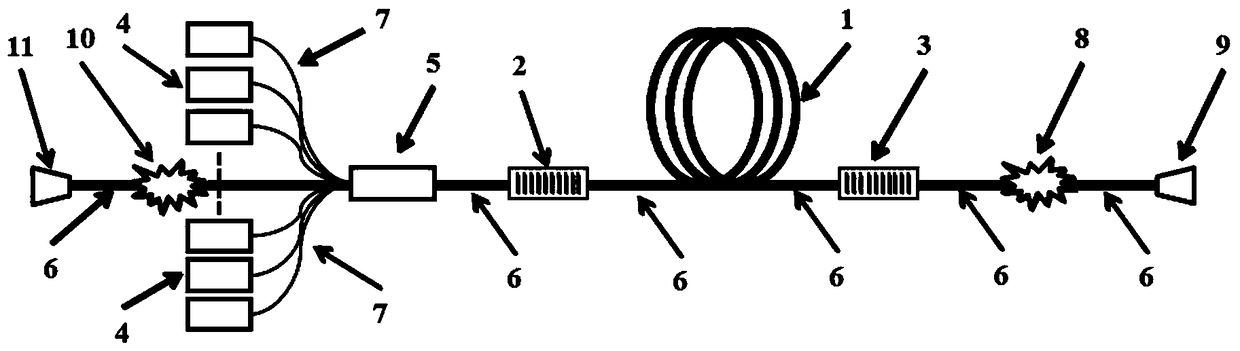

[0029] A linear cavity all-fiber laser oscillator with double-ended output, the structure diagram is as follows figure 1 As shown, it includes gain fiber 1, backward fiber grating 2, forward fiber grating 3, fiber-coupled semiconductor laser 4, pump signal beam combiner 5, signal energy transmission fiber 6, pump energy transmission fiber 7, forward Cladding light filter 8, forward output fiber end cap 9, backward cladding light filter 10, backward output fiber end cap 11; backward fiber Bragg grating 2, gain fiber 1, and forward fiber Bragg grating 3 pass through The signal energy transmission optical fiber 6 is sequentially connected to form a fiber laser resonator; the backward fiber grating 2, the gain fiber 1, and the forward fiber grating 3 are connected sequentially through the signal energy transmission optical fiber 6 to form a fiber laser resonator; the signal energy transmission optical fiber 6 will The forward fiber grating 3, the forward cladding optical filter 8 ...

Embodiment 2

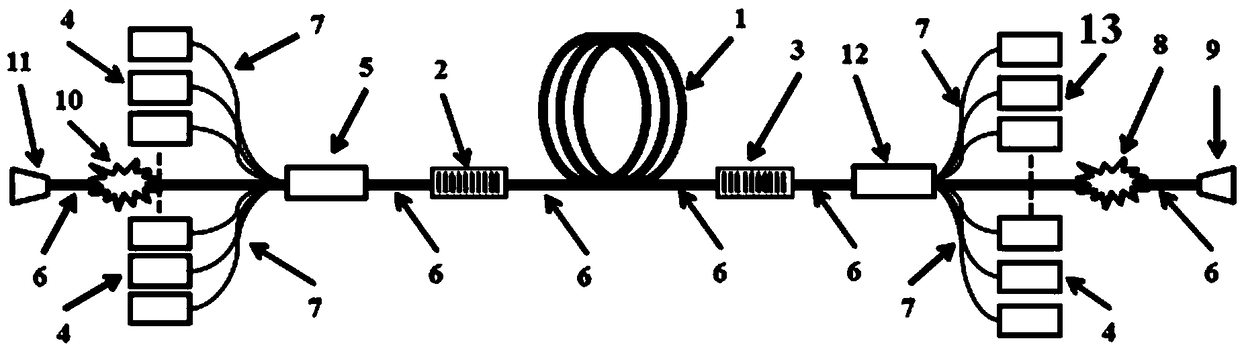

[0038] A double-ended pumping, double-ended output linear cavity all-fiber laser oscillator, its structure schematic diagram is as follows figure 2 shown. On the basis of Embodiment 1, a second pump signal combiner 12 and a corresponding second fiber-coupled semiconductor laser 13 are added to form a double-end pumped fiber laser oscillator, and the pump power injected into the resonator is increased. The second pump signal combiner 12 is arranged between the forward fiber grating 3 and the forward cladding optical filter 8; the second pump signal combiner 12 includes a signal input arm, a signal output arm, a or a plurality of pump input arms; the signal output arm of the second pump signal combiner 12 is connected to the forward fiber grating 3 through the signal energy transmission fiber 6, and its signal input arm is connected to the forward layer optical filter 8 through the signal The energy transmission fiber 6 is connected, and its pump input arm is connected to the ...

Embodiment 3

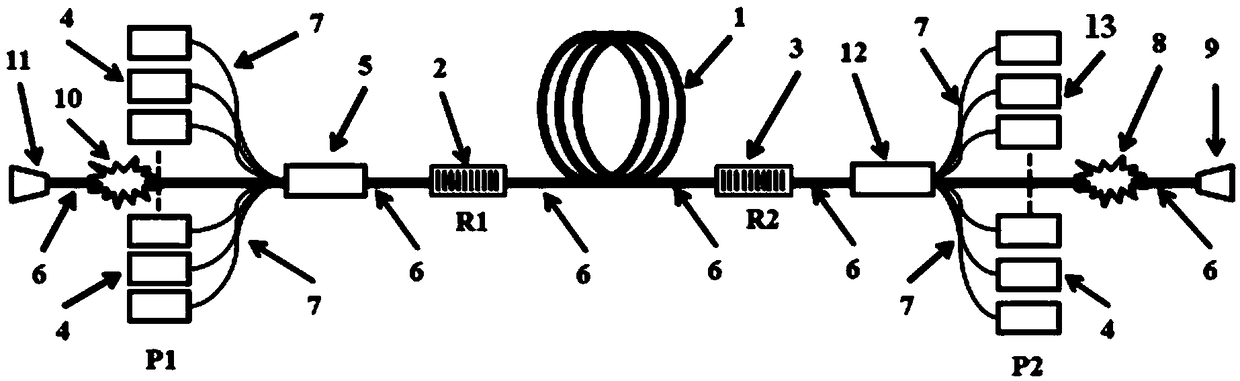

[0041] A linear cavity all-fiber laser oscillator with the same output power at both ends, its schematic structure is as follows image 3 shown. On the basis of embodiment 2, the backward fiber grating and the forward fiber grating are selected as fiber gratings with equal reflectivity, that is, the reflectivity R1 of the forward output reflection grating 3 is equal to the reflectivity R2 of the backward output grating 2; and , the total power of the fiber-coupled semiconductor laser 4 injected into the forward pump signal combiner 5 is equal to the total power of the second fiber-coupled semiconductor laser 13 injected into the backward pump signal combiner 12, that is, the fiber-coupled semiconductor laser 4 The total power P1 injected into the pump signal combiner 5 and the total power P2 injected into the second pump signal combiner 12 are equal to ensure that the output power at both ends of the oscillator is equal. The structural diagram is as follows image 3 shown.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com