Preparation method of catalyst for hydrotreating of fluidized bed

A technology for hydrotreating and catalyst, applied in physical/chemical process catalysts, chemical instruments and methods, processing hydrocarbon oil, etc., can solve the problems of short catalyst service cycle, high catalyst bed pressure drop, harsh catalytic reaction conditions, etc. Achieve the effect of improving activity and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

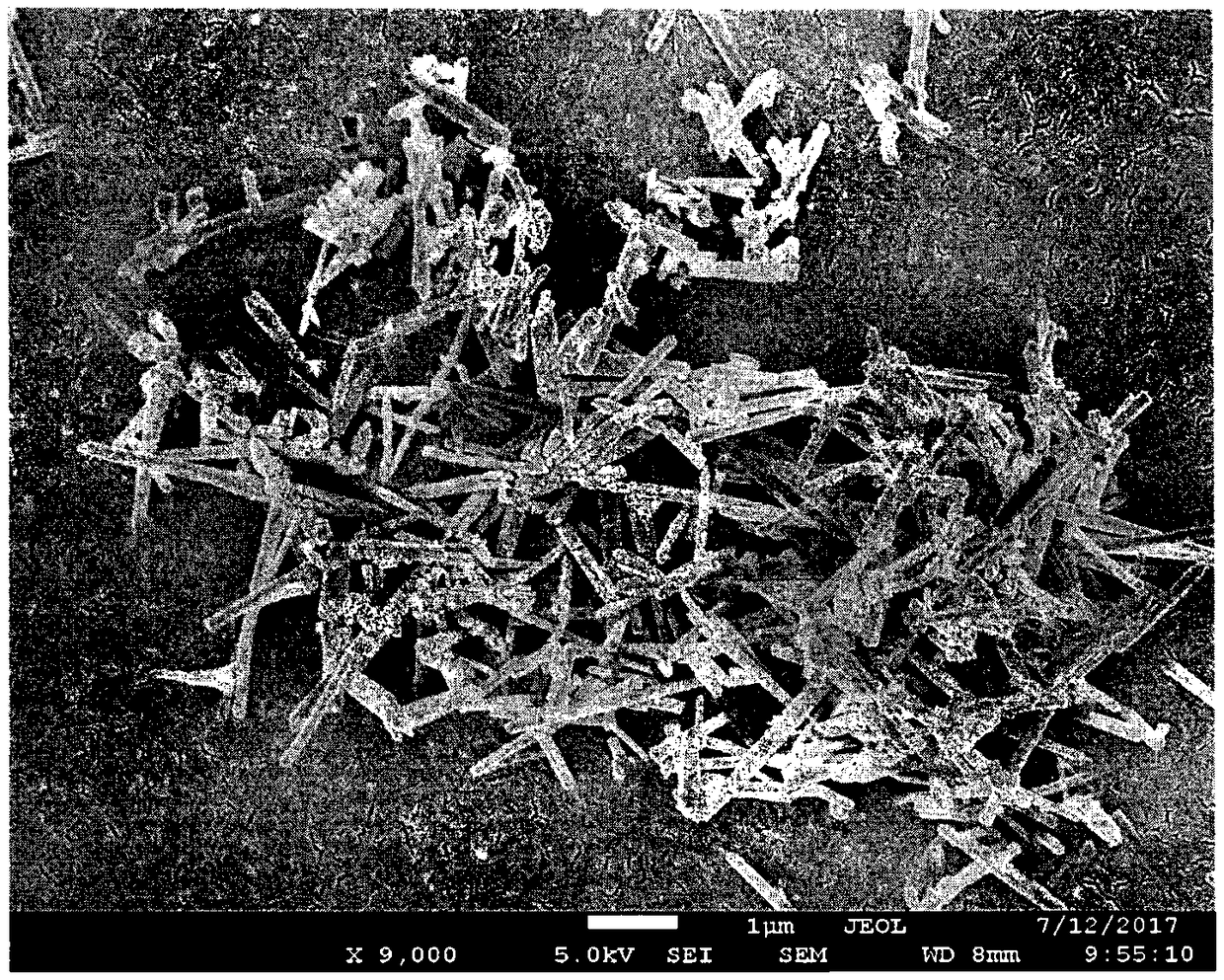

[0028] Take by weighing basic ammonium aluminum carbonate 50g, be that the xylitol solution of 20wt% with mass concentration impregnates above-mentioned material 2 hours, the material after impregnating is filtered with pseudo-boehmite dry rubber powder 200g (Wenzhou Fine Crystal Alumina Co., Ltd. Produced by the company, the dry basis content of alumina is 70wt%) and 0.2g of scallop powder are mixed evenly, and an appropriate amount of aqueous solution dissolved in 3 grams of acetic acid is added to the mixture, extruded and formed, and the formed product is dried at 120°C for 8 hours.

[0029] Weigh 100 grams of the dried strip-shaped material and place it in a spray-dipping pan, spray and impregnate the above-mentioned carrier with 10 mL of sorbitol aqueous solution with a mass concentration of 15%, and dry the impregnated carrier at 120°C for 7 hours. The aluminum oxide carrier was obtained by calcining at 650° C. for 6 hours under a nitrogen atmosphere, and then at 650° C....

Embodiment 2

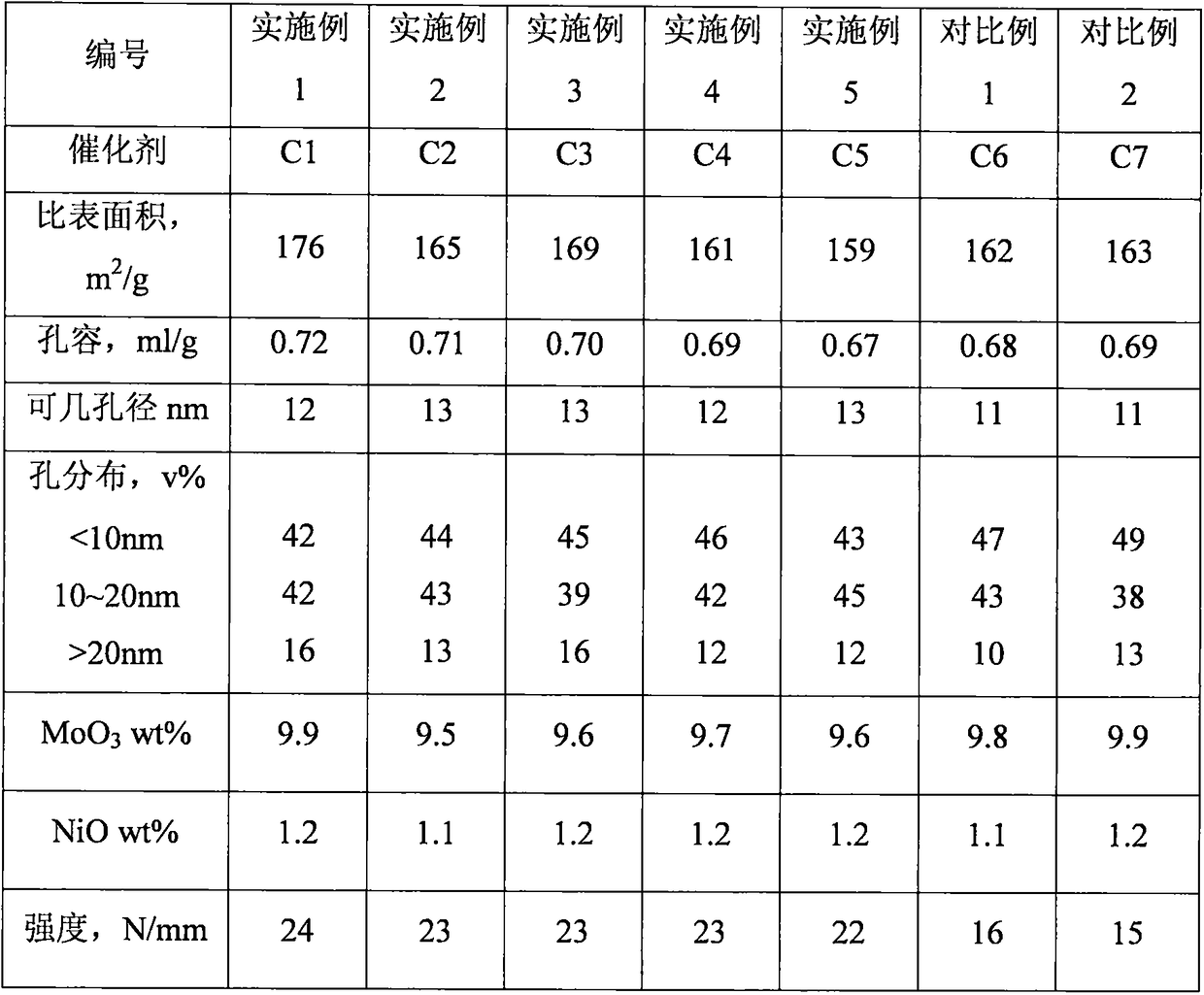

[0032] With embodiment 1, just the add-on of basic aluminum ammonium carbonate is 30 grams, what used when impregnating basic aluminum carbonate is the 40wt% tetrose solution of mass concentration, what used when spraying and impregnating forming carrier is that mass concentration is 20wt% mannitol solution, the amount of the solution is 20ml, the calcination temperature of the carrier under the atmosphere of nitrogen and oxygen is 700°C and the calcination time is 6 hours, and the catalyst C2 is obtained. The properties of the catalyst are shown in Table 1.

Embodiment 3

[0034]Same as Example 1, except that the add-on of ammonium basic aluminum carbonate is 40 grams. When impregnating basic ammonium aluminum carbonate, the glucose solution with a mass concentration of 30wt% is used, and the mass concentration used when spraying and impregnating the forming carrier is 10wt. % pentose solution, the consumption of solution is 15ml, and the calcination temperature of carrier under nitrogen and oxygen atmosphere is 750 ℃ of calcination time and is 6 hours, makes catalyst C3, and the property of this catalyzer is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com