Preparation method for pressure-assisted size-controllable hydrothermal carbon spheres and prepared hydrothermal carbon spheres

A hydrothermal carbon and size technology, applied in the preparation/purification of carbon, nano-carbon, etc., can solve the problems of poor size controllability and narrow adjustable size of carbon balls, and achieve uniform size, good size uniformity, and improved stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of pressure-assisted size-controllable hydrothermal carbon spheres of the present invention comprises the following steps:

[0029] S1. Configure the concentration of glucose solution to be 0.1M-2M;

[0030] S2. Put the glucose solution obtained in step S1 into the autoclave, seal the autoclave, and feed gas through the air inlet on the autoclave to increase the pressure by 0.5-3.0 MPa, that is, pressurize to 0.6-3.1 MPa;

[0031] S3. Heating the autoclave in step S2 to 160-220° C. for 2-12 hours, then cooling to room temperature;

[0032] S4. Washing and drying the product obtained in step S3 to obtain the target product.

[0033] In the step S2, the glucose solution is placed in an autoclave and sealed with a thread.

[0034] The dosage of the glucose solution is 1 / 3-2 / 3 of the volume of the autoclave.

[0035] Said pressurization is to remove the self-generated pressure produced by the autoclave at room temperature, and the extra increased p...

Embodiment 1

[0041] 1) Configure the concentration of glucose solution as 1M;

[0042] 2) Take 60mL of the glucose solution with the above concentration, put it into a 100mL autoclave, seal it, feed nitrogen gas to increase the pressure by 0.5MPa, heat to 200°C for 12h, and naturally cool to room temperature after the reaction to obtain a carbon sphere solution.

[0043] 3) Centrifuge the above solution at 3000r / min, and repeatedly ultrasonically disperse and centrifuge with absolute ethanol and deionized water until the cleaning solution is clear.

[0044] 4) Dry the above-mentioned cleaned carbon spheres in a vacuum oven at 60° C. for 12 hours to obtain hydrothermal carbon spheres.

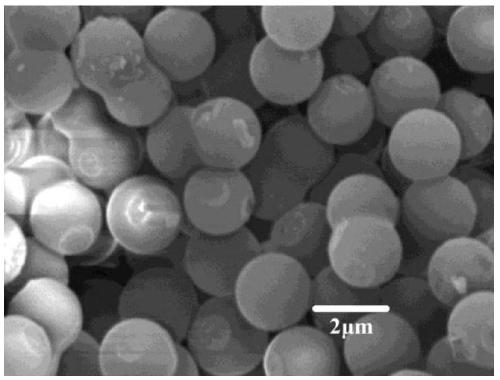

[0045] figure 1 Shown is the scanning electron microscope image of the carbon spheres obtained in Example 1. It can be seen from the figure that the carbon spheres have uniform size and good dispersion, and the size is about 200nm.

Embodiment 2

[0047] 1) Configure the concentration of glucose solution to be 0.5M;

[0048] 2) Take 60mL of the glucose solution with the above concentration, put it into a 100mL autoclave, seal it, feed nitrogen gas to increase the pressure by 1.0MPa, heat to 180°C for 10h, and naturally cool to room temperature after the reaction to obtain a carbon sphere solution.

[0049] 3) Centrifuge the above solution at 5000r / min, and repeatedly ultrasonically disperse and centrifuge with absolute ethanol and deionized water until the cleaning solution is clear.

[0050] 4) Dry the above-mentioned cleaned carbon spheres in a vacuum oven at 60° C. for 12 hours to obtain hydrothermal carbon spheres.

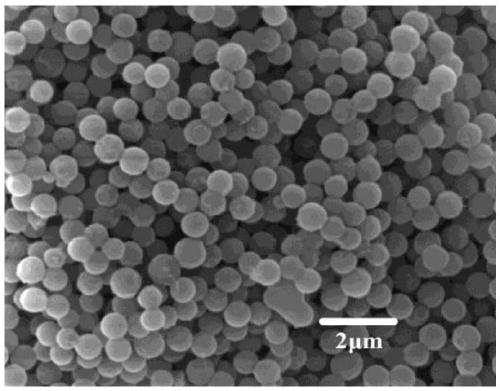

[0051] figure 2 Shown is the scanning electron microscope image of the carbon spheres obtained in Example 2. It can be seen from the figure that the carbon spheres have a uniform diameter, good dispersion, and a size of about 800 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com