Method for preparing titanium dioxide by using high-titanium-type blast furnace slag

A technology of titanium dioxide and blast furnace slag, applied in the direction of titanium dioxide, titanium oxide/hydroxide, titanium halide, etc., can solve the problem of waste of materials, and achieve the effect of avoiding waste of resources, significant economic benefits and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

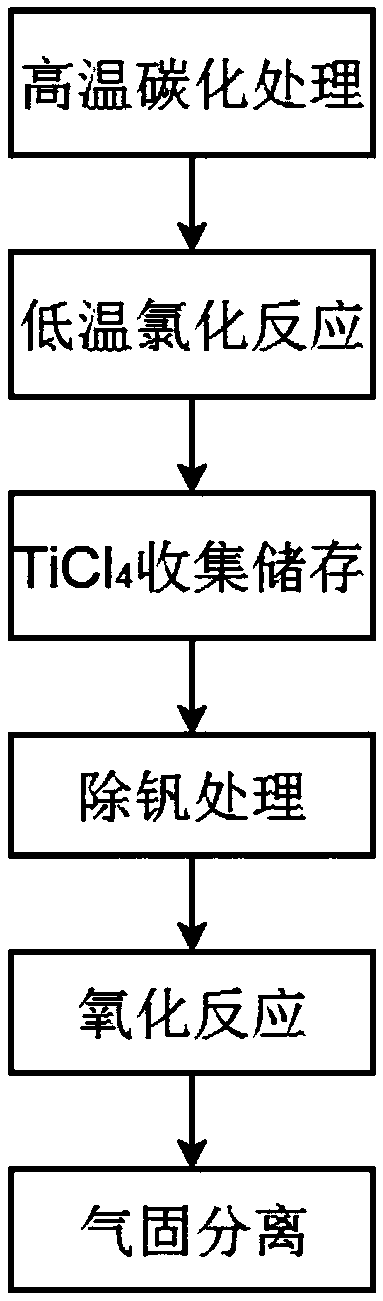

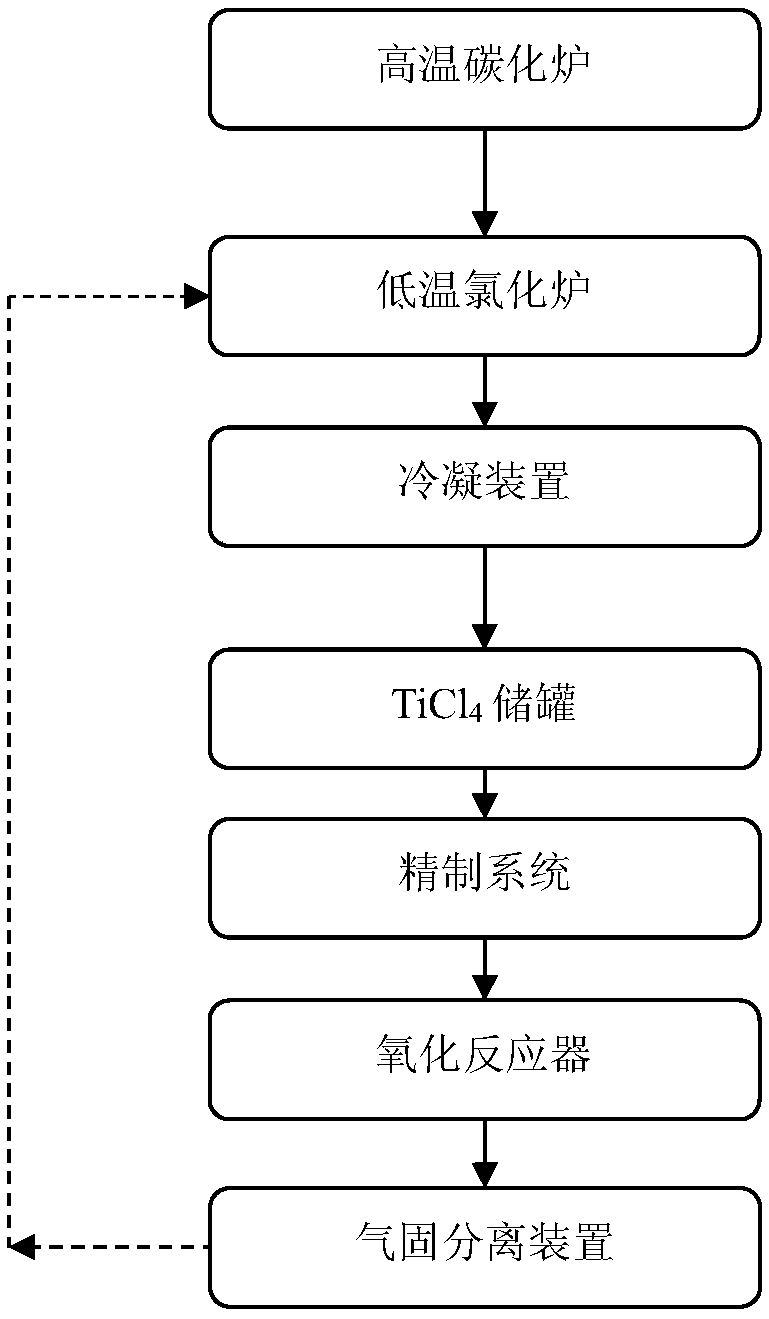

[0043] A. Carry out high-temperature carbonization treatment of high-titanium blast furnace slag to make TiO 2Transformed into TiC, after cooling and crushing, carbide slag is formed as the raw material required for the low-temperature chlorination process. The carbide slag is crushed and processed into separate materials with a particle size of 200-300 mesh, and the weight percentage of TiC in the material is 8-11%;

[0044] B. Supply the carbide slag and chlorine gas obtained in step A to the chlorination reactor in a mass ratio of 3:1, and carry out low-temperature selective chlorination reaction at 580-650°C for 30-35 minutes to obtain TiCl-containing 4 Chlorination reaction mixture of gas, the gas mixture is condensed to room temperature to obtain liquid crude TiCl 4 (liquid crude TiCl 4 can be stored in dedicated storage tanks);

[0045] C, adopt fatty acid to step B gained liquid thick TiCl 4 (fatty acid and crude TiCl 4 The mass ratio is 1:57.5) to remove vanadium ...

Embodiment 2

[0049] A. Carry out high-temperature carbonization treatment of high-titanium blast furnace slag to make TiO 2 Transformed into TiC, after cooling and crushing, carbide slag is formed as the raw material required for the low-temperature chlorination process. The carbide slag is crushed and processed into separate materials with a particle size of 200-300 mesh, and the weight percentage of TiC in the material is 8-11%;

[0050] B. Supply the carbonized slag and chlorine gas obtained in step A to the chlorination reactor at a mass ratio of 1:3, and carry out a low-temperature selective chlorination reaction at 580-650°C for 30-35 minutes to obtain TiCl-containing 4 Chlorination reaction mixture of gas, the gas mixture is condensed to room temperature to obtain liquid crude TiCl 4 (liquid crude TiCl 4 can be stored in dedicated storage tanks);

[0051] C, adopt fatty acid to step B gained liquid thick TiCl 4 (fatty acid and crude TiCl 4 The mass ratio is 1:58) to remove vanad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com