Environment-friendly heat conduction coating material as well as preparation method and application thereof

A thermally conductive coating and environmental protection technology, applied in the field of coatings, can solve the problem of no heat dissipation effect, etc., and achieve the effects of improving the use range, fast drying speed and good scratch resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

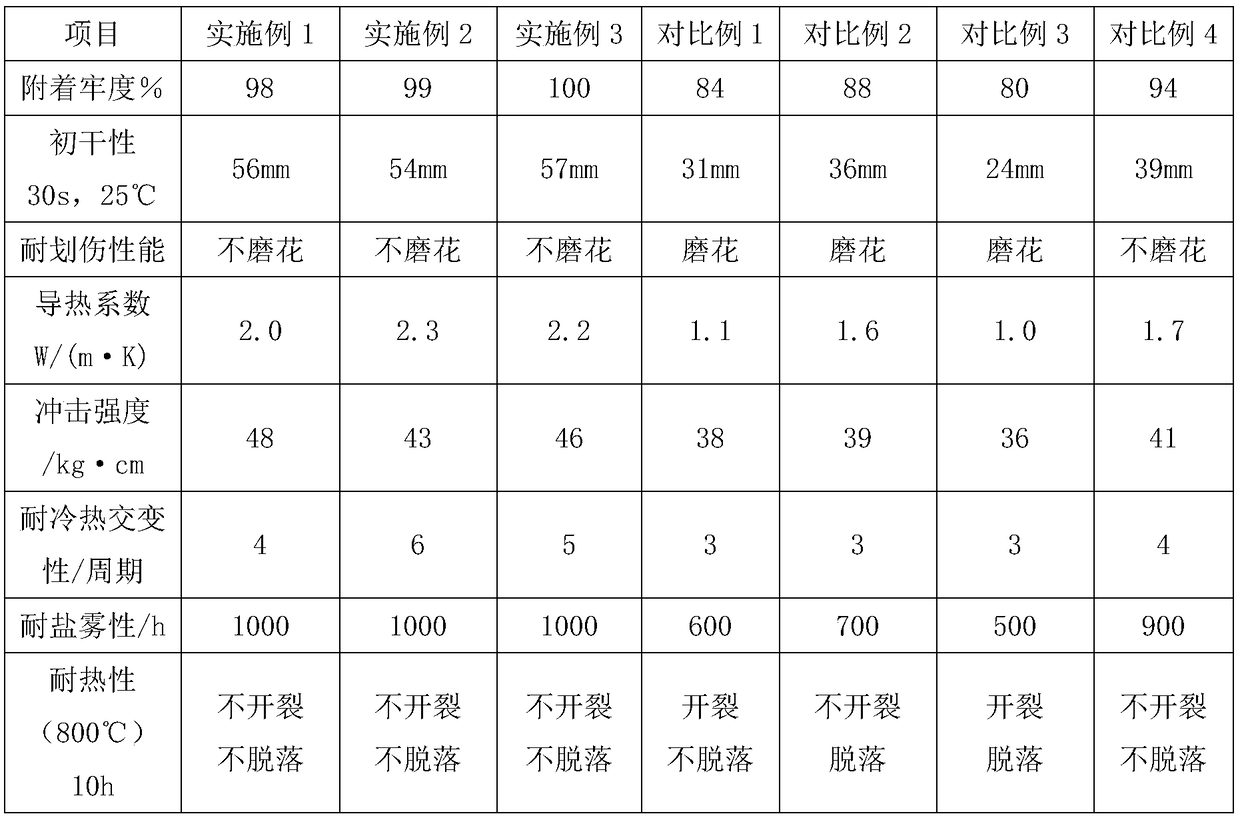

Examples

Embodiment 1

[0021] An environment-friendly heat-conducting coating comprises the following steps: 68 parts of water-based polyurethane, 9 parts of caffeic acid, 11 parts of charantin, 8 parts of potassium tetraborate, and 6 parts of zinc sulfate heptahydrate.

[0022] A preparation method of an environmentally friendly thermally conductive coating, comprising the following steps: (1) preparation of modified water-based polyurethane: mixing caffeic acid and charantin, adding 45 parts of ethanol solution with a mass fraction of 85%, and stirring at 75°C for reaction 6h; the resultant was distilled under reduced pressure to recover ethanol, then cooled to 25°C, then added water-based polyurethane and 200 parts of water, stirred and mixed for 2h, then heated to 75°C and stirred for 20min; (2) Potassium tetraborate and sulfuric acid heptahydrate Mix zinc with 20 parts of water respectively to make potassium tetraborate solution and zinc sulfate heptahydrate solution; (3) mix the modified water-...

Embodiment 2

[0024] An environment-friendly heat-conducting coating comprises the following steps: 84 parts of water-based polyurethane, 4 parts of caffeic acid, 16 parts of charantin, 4 parts of potassium tetraborate, and 12 parts of zinc sulfate heptahydrate.

[0025] A preparation method of an environmentally friendly heat-conductive coating, comprising the following steps: (1) preparation of modified water-based polyurethane: mixing caffeic acid and charantin, adding 60 parts of ethanol solution with a mass fraction of 85%, and stirring at 70°C for reaction 15h; the resultant was distilled under reduced pressure to recover ethanol, then cooled to 20°C, then added water-based polyurethane and 350 parts of water, stirred and mixed for 1h, then heated to 90°C and stirred and mixed for 10min; (2) Potassium tetraborate and sulfuric acid heptahydrate Mix zinc with 40 parts of water evenly to make potassium tetraborate solution and zinc sulfate heptahydrate solution; (3) mix the modified water...

Embodiment 3

[0027] An environment-friendly heat-conducting coating comprises the following steps: 77 parts of water-based polyurethane, 6 parts of caffeic acid, 13 parts of charantin, 6 parts of potassium tetraborate, and 9 parts of zinc sulfate heptahydrate.

[0028] A preparation method of an environmentally friendly heat-conductive coating, comprising the following steps: (1) preparation of modified water-based polyurethane: mixing caffeic acid and charantin, adding 50 parts of ethanol solution with a mass fraction of 85%, and stirring at 72°C for reaction 10 hours; the resultant was distilled under reduced pressure to recover ethanol, then cooled to 22°C, then water-based polyurethane and 280 parts of water were added, stirred and mixed for 1.6 hours, then heated to 82°C and stirred for 17 minutes. (2) Mix potassium tetraborate and zinc sulfate heptahydrate with 32 parts of water respectively to prepare potassium tetraborate solution and zinc sulfate heptahydrate solution. (3) Mix the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com