Method for determining content of methanesulfonic acid in busulfan

A determination method and technology of methanesulfonic acid, applied in the field of medicine, can solve the problems such as the method without the content of methanesulfonic acid in busulfan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Instruments and Conditions:

[0029] HPLC equipped with CAD: Ultimate 3000, DIONEX Corona Veo RS CAD

[0030] Chromatographic column: ion chromatography column

[0031] Mobile phase: A: 0.1% trifluoroacetic acid in water B: 0.2% trifluoroacetic acid in acetonitrile.

[0032] The gradient is as follows: 0min-20min, the proportion of organic phase is 5%-95%; 20min-20.1min, the proportion of organic phase is 95%-5%; 20.1min-30min, the proportion of organic phase is 5%.

[0033] Flow rate: 1.0mL / min

[0034] Column temperature: 25°C

[0035] Vaporization temperature: 25°C

[0036] Injection volume: 5μL

[0037] Collection time: 21min

[0038] Diluent: Acetonitrile

[0039] Experimental steps:

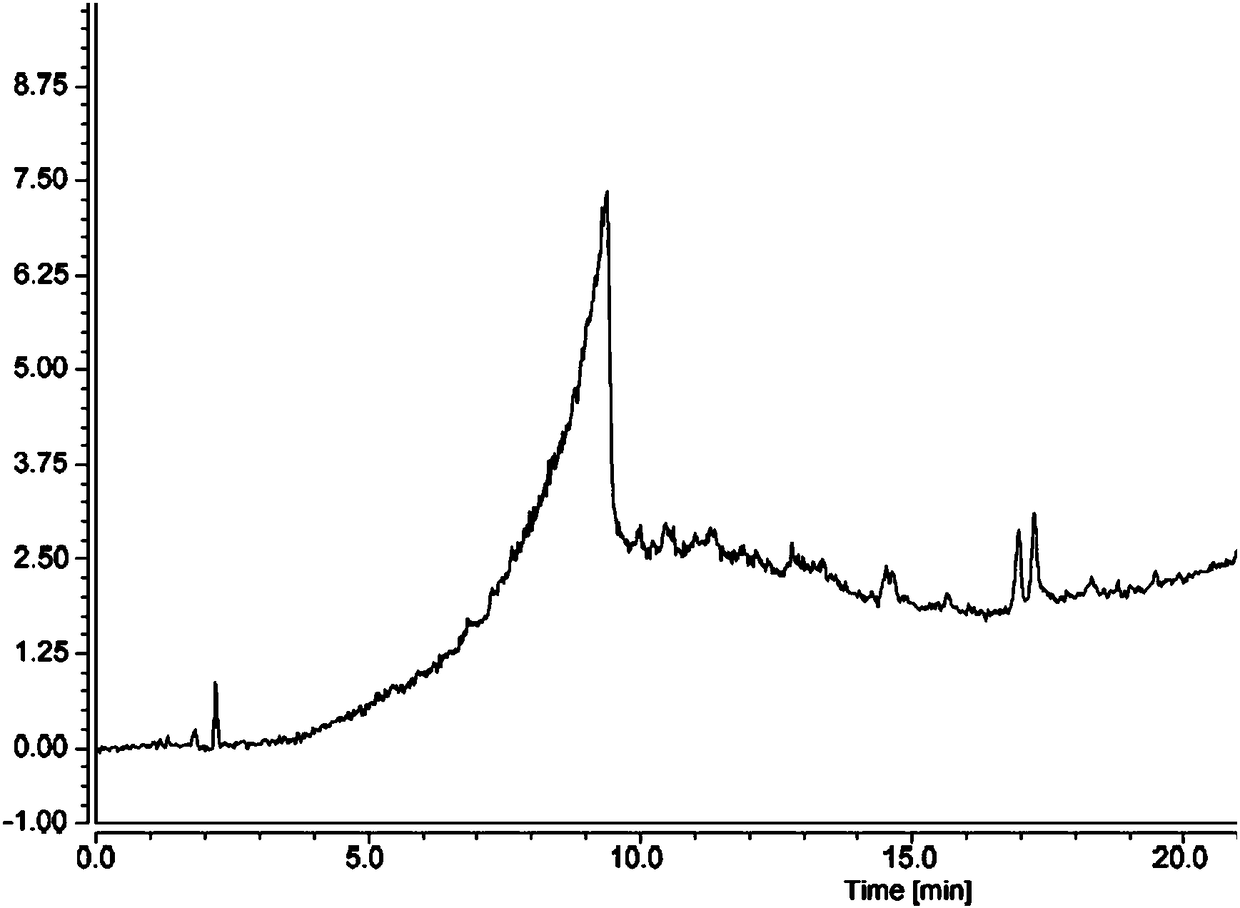

[0040] Blank sample: pipette 1.0mL of acetonitrile into a 2mL HPLC vial and inject. Record the chromatogram, typical spectrum see figure 1 .

Embodiment 2

[0042] Instruments and Conditions:

[0043] HPLC equipped with CAD: Ultimate 3000, DIONEX Corona Veo RS CAD

[0044] Chromatographic column: ion chromatography column

[0045] Mobile phase: A: 0.1% trifluoroacetic acid in water B: 0.2% trifluoroacetic acid in acetonitrile.

[0046] The gradient is as follows: 0min-20min, the proportion of organic phase is 5%-95%; 20min-20.1min, the proportion of organic phase is 95%-5%; 20.1min-30min, the proportion of organic phase is 5%.

[0047] Column temperature: 25°C

[0048] Vaporization temperature: 25°C

[0049] Injection volume: 5μL

[0050] Collection time: 21min

[0051] Diluent: Acetonitrile

[0052] Experimental steps:

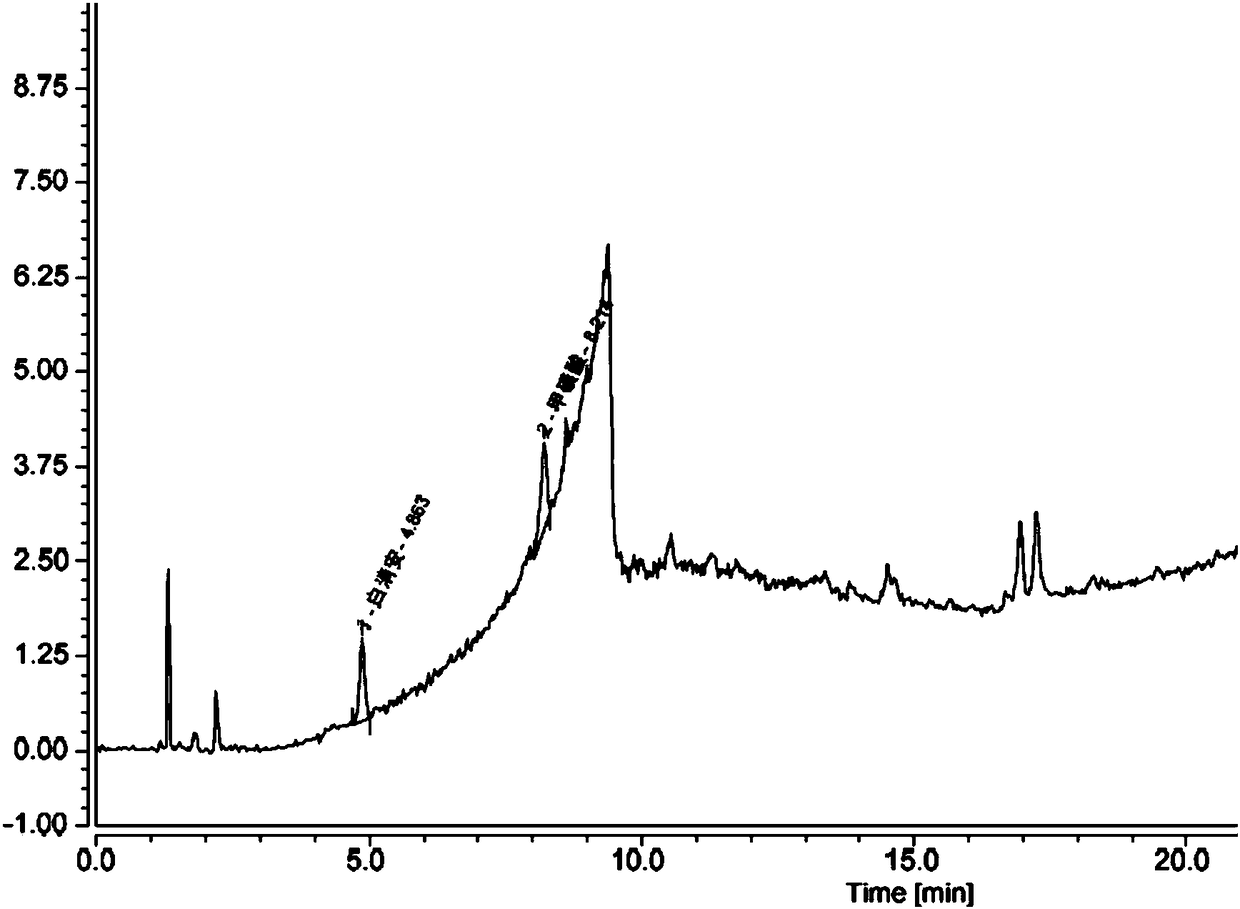

[0053] (1) Brenitrazam and methanesulfonic acid stock solution A: Weigh 50 mg of the white nitramide reference substance and 50 mg of the methanesulfonic acid reference substance, accurately weigh it in a 25 mL volumetric flask, dissolve it with diluent and dilute to the mark, and mix well. (Dinitrazol co...

Embodiment 3

[0056] Instruments and Conditions:

[0057] HPLC equipped with CAD detectors: Ultimate 3000, DIONEX Corona Veo RS CAD

[0058] Chromatographic column: ion chromatography column

[0059] Mobile phase: A: 0.1% trifluoroacetic acid in water B: 0.2% trifluoroacetic acid in acetonitrile.

[0060] The gradient is as follows: 0min-20min, the proportion of organic phase is 5%-95%; 20min-20.1min, the proportion of organic phase is 95%-5%; 20.1min-30min, the proportion of organic phase is 5%.

[0061] Flow rate: 1.0mL / min

[0062] Column temperature: 25°C

[0063] Vaporization temperature: 25°C

[0064] Injection volume: 5μL

[0065] Collection time: 21min

[0066] Diluent: Acetonitrile

[0067] Experimental steps:

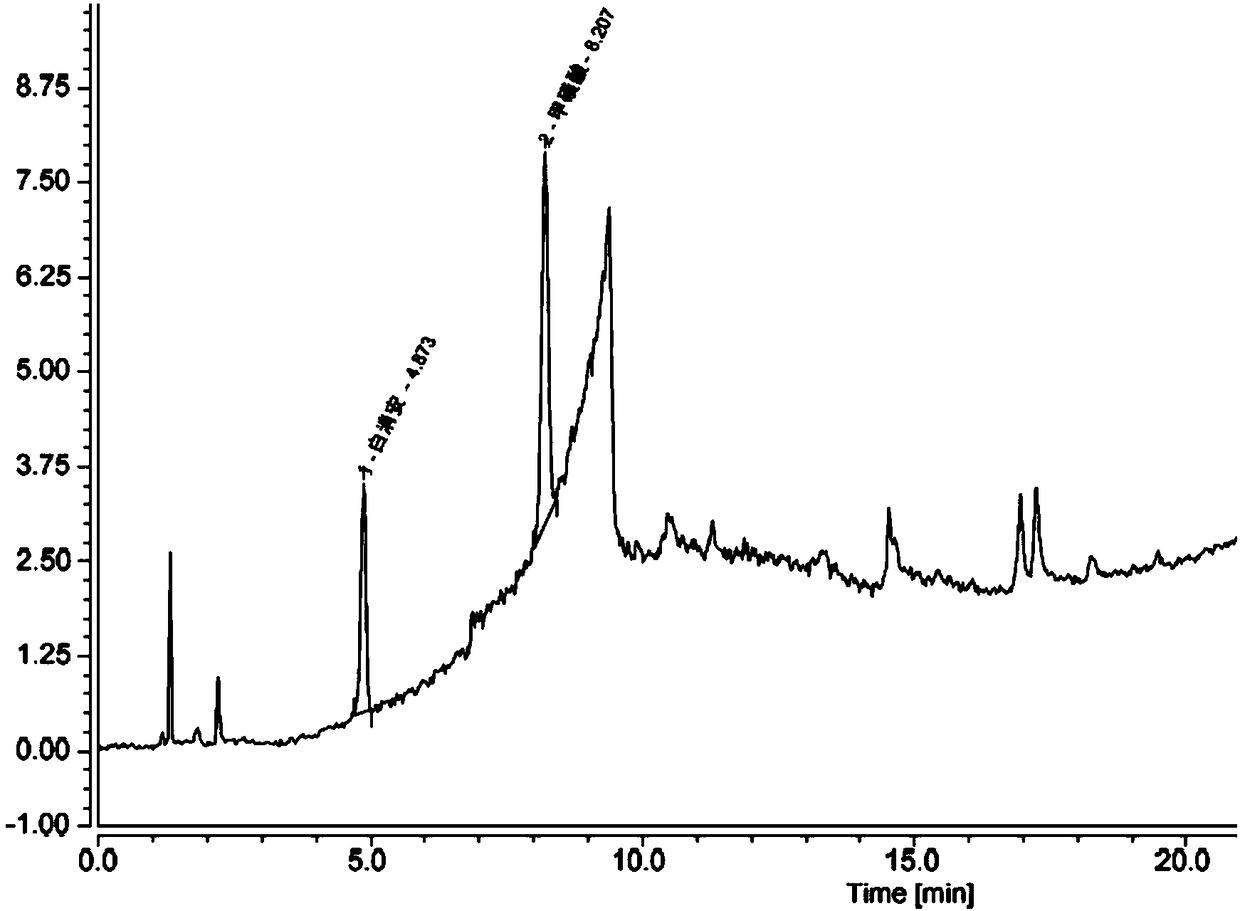

[0068] (1) Brenitrazam and methanesulfonic acid stock solution A: Weigh 50 mg of the white nitramide reference substance and 50 mg of the methanesulfonic acid reference substance, accurately weigh it in a 25 mL volumetric flask, dissolve it with diluent and dilute t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com