Method for preparing benzodiazepine molecule surface blotting solid-phase extractant

A solid-phase extraction agent and surface imprinting technology, applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc., can solve the leakage of template molecules, unsatisfactory mass transfer rate, and affect the accurate quantification of trace analytes Detection and other problems, to achieve the effect of eliminating the interference of impurities, good selection of adsorption and separation capabilities, and not easy to fragment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 0.19g of estazolam in 5mL of methanol, then add 1mL of γ-aminopropyltriethoxysilane, 1.1mL of phenyltrimethoxysilane, stir for about 0.5 hours, add 2mL of tetraethoxysilane, and then Stir for 5 minutes, add 0.5 g of activated silica gel (amorphous, particle size 19-37 μm), and finally add 1 mL of water and adjust the pH to 3 with hydrochloric acid to catalyze hydrolysis and condensation. After the above mixed solution was fully stirred, it was allowed to stand still for about 24 hours to completely hydrolyze and condense, then filtered, and vacuum-dried at 100°C to constant weight. The template molecules were removed by Soxhlet extraction with acetic acid / methanol (1:9, V / V) solution, and then the residual acetic acid on the surface molecularly imprinted polymer was removed with methanol, and finally, vacuum-dried at 80°C for further use.

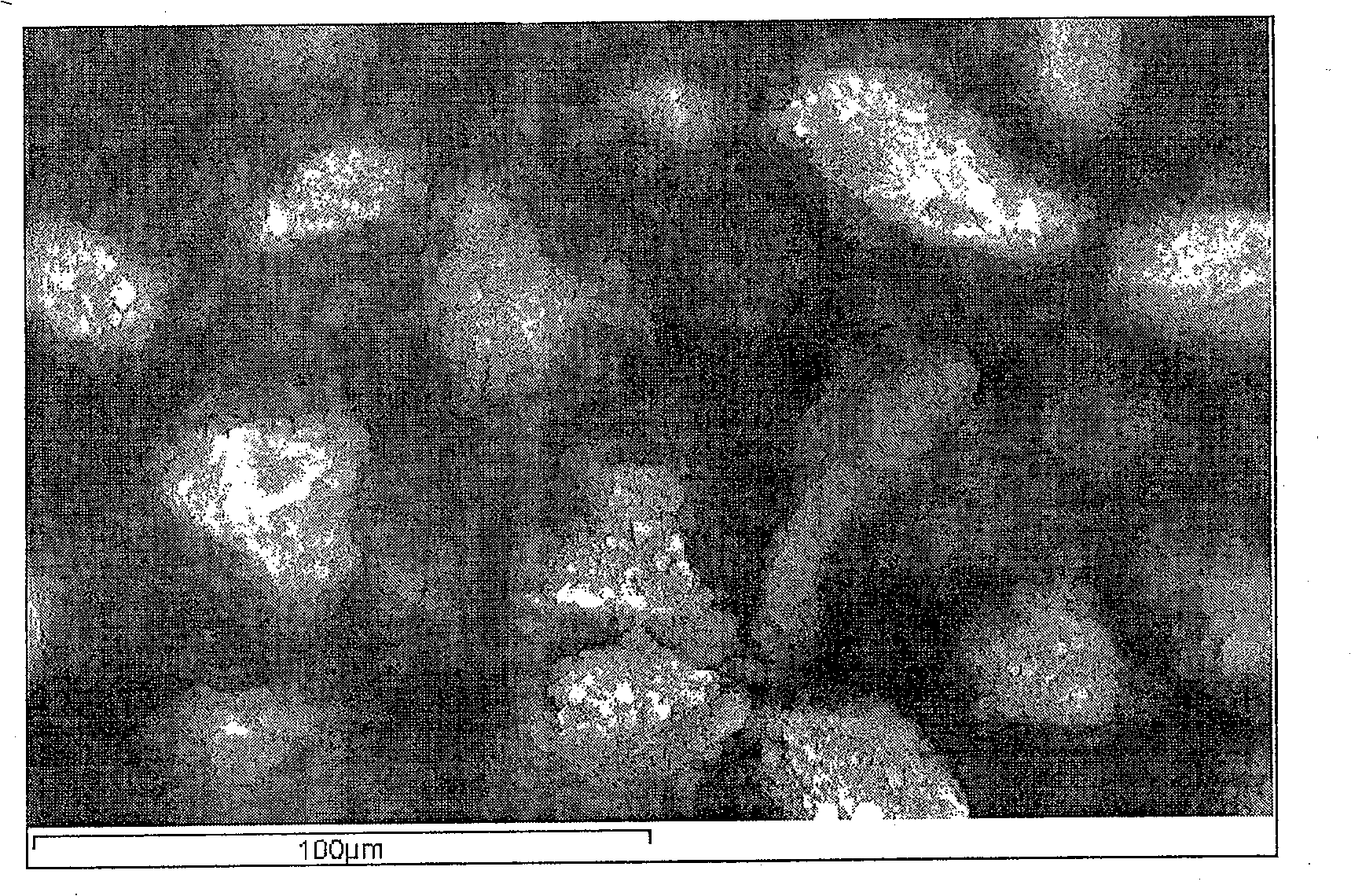

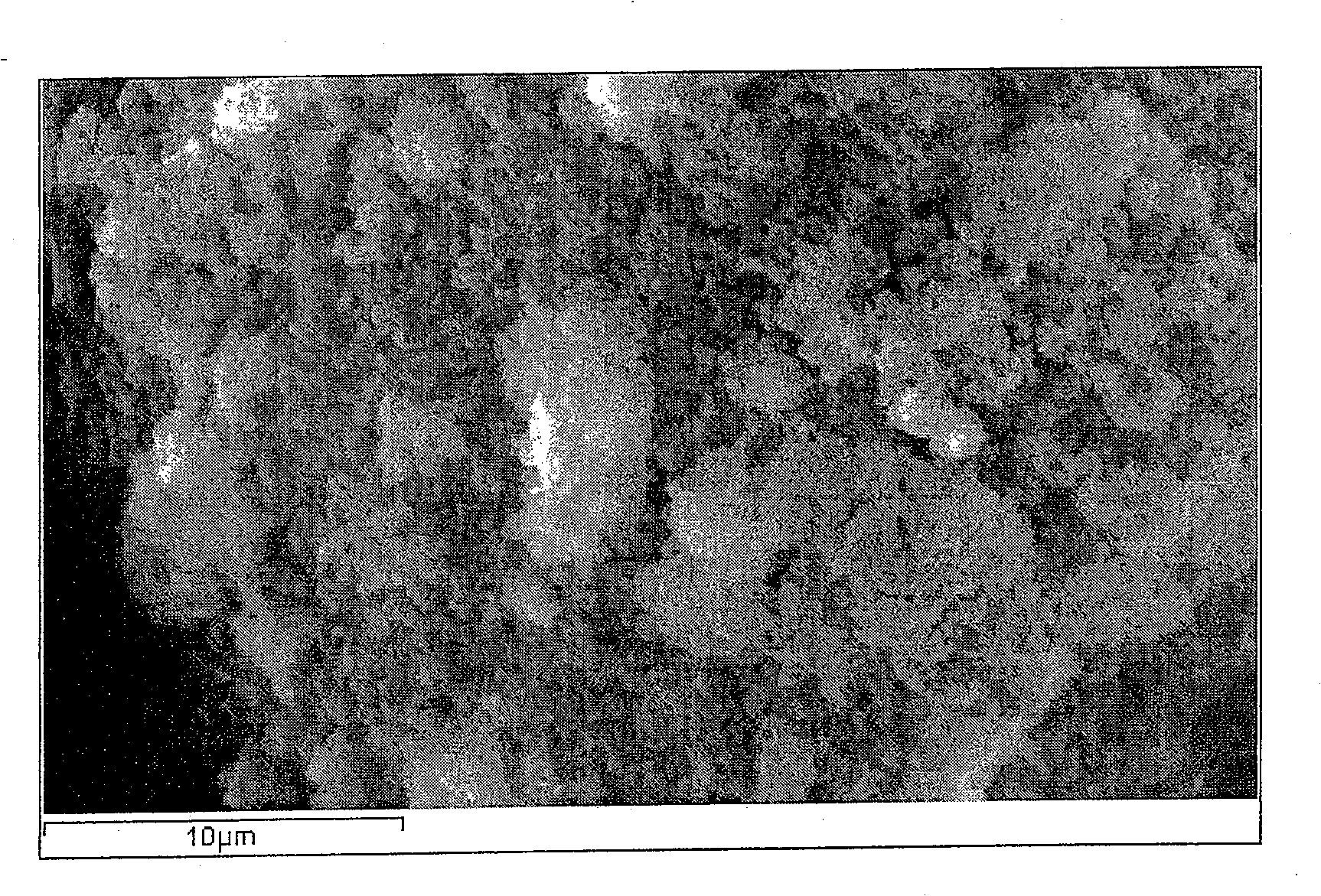

[0024] figure 1 and 2 They are the SEM images of the solid phase extraction agent synthesized in Example 1 enlarged 500 ...

Embodiment 2

[0028] Dissolve 0.62g of estazolam in 15mL of methanol, then add 1mL of γ-aminopropyltrimethoxysilane, 0.8mL of phenyltrimethoxysilane, stir for about 1 hour, add 4mL of tetramethoxysilane, and then stir For 5 minutes, add 1.8 g of activated silica gel (spherical type, particle size 5-10 μm), and finally add 1 mL of water and adjust the pH to 4 with hydrochloric acid to catalyze the hydrolysis and condensation. After the above mixed solution was fully stirred, it was allowed to stand still for about 12 hours to completely hydrolyze and condense, then filtered, and vacuum-dried at 90°C for 8 hours. The template molecule was removed by Soxhlet extraction with acetic acid / acetonitrile (1:9, V / V) solution, and then the residual acetic acid on the surface molecularly imprinted polymer was removed with methanol, and finally, vacuum-dried at 60°C for use.

[0029] The microsphere solid-phase extraction agent prepared by the above method is used to process biological samples. The expe...

Embodiment 3

[0032] Dissolve 0.27g of diazepam in 15mL of methanol, then add 1mL of γ-aminopropyltriethoxysilane, 1mL of phenyltriethoxysilane, stir for about 0.5 hours, add 4mL of tetraethoxysilane, and then stir for 5 minutes , add 1.8g of activated silica gel (spherical, particle size 5-10μm), and finally add 2mL of water and adjust the pH to 5 with hydrochloric acid to catalyze the hydrolysis condensation. After the above mixed solution was fully stirred, it was allowed to stand still for about 24 hours to completely hydrolyze and condense, then filtered and vacuum dried at 110°C for 8 hours. The template molecule was removed by Soxhlet extraction with acetic acid / methanol (1:9, V / V) solution, and then the residual acetic acid on the surface molecularly imprinted polymer was removed with methanol / ethanol, and finally, vacuum-dried at 80°C for further use.

[0033] In order to prove that the prepared microsphere solid-phase extraction agent has selective adsorption to template molecules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com