A direct fluid-solid coupling heat transfer analysis method for engine cooling water jacket

A technology of fluid-solid coupling and cooling water jacket, which is applied in computer-aided design, special data processing applications, instruments, etc., can solve problems such as the inability to effectively evaluate the heat transfer process and coolant flow conditions, and achieve improved service life and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

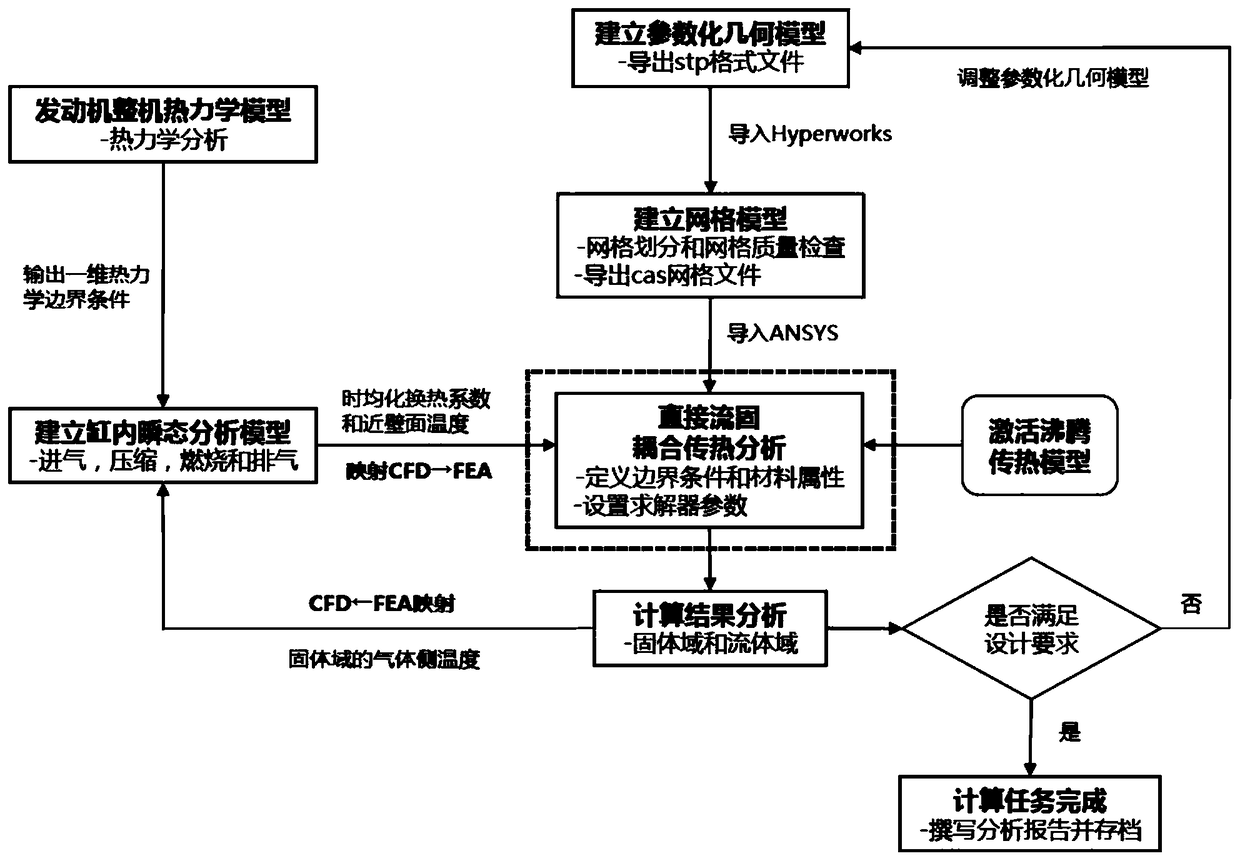

[0027] In this embodiment, a direct fluid-solid coupling heat transfer analysis method of the engine cooling water jacket considering the influence of boiling heat transfer, such as figure 1 As shown, it mainly includes the following steps: 1. Establish the parametric geometric model of the solid domain and the fluid domain, and export the stp format file; 2. Perform grid division to establish the grid model, check the grid quality, and then export the cas grid 3. Define the material properties in ANSYS software; 4. Establish the engine thermodynamic model in GT-PowerGT-Power software, and perform the engine thermodynamics simulation for the rated operating point of the engine, so as to obtain the in-cylinder transient analysis The required one-dimensional thermodynamic boundary conditions; define the boundary conditions in ANSYS software, including mapping the CFD data of the time-averaged heat transfer coefficient and the temperature near the wall to the FEA surface mesh of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com