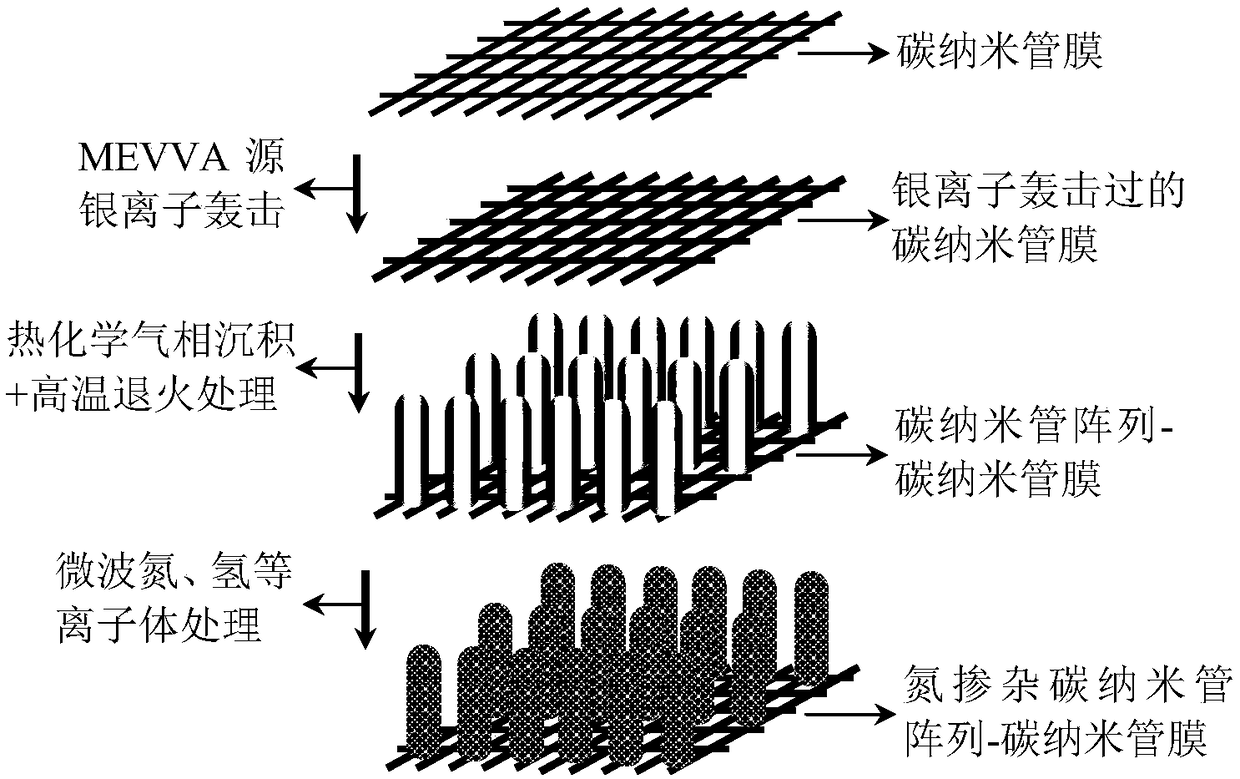

A method for improving field emission properties of flexible composites with carbon nanotube array and carbon nanotube film

A carbon nanotube array and carbon nanotube film technology, applied in the field of preparation and application of nanomaterials, can solve the problems of low field emission current density, large number of field emission points, poor stability, etc., and achieve enhanced tube-base bonding. , The effect of field electron emission enhancement and bonding force enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Pretreatment of carbon nanotube film and deposition catalyst:

[0027] First cut the commercially available carbon nanotube film (Fig. 21: the optical picture of the original carbon nanotube film; Fig. 22: the low-magnification scanning electron microscope picture of the original carbon nanotube film) into small pieces of 2cm × 2cm, and then use metal vapor vacuum arc The ion source (MEVVA source) carried out energy-carrying silver ion bombardment treatment on it, and during the bombardment, the sample stage was kept rotating at a constant speed, the sample stage bias voltage was set to -10kV, the beam current was 5 mA, and the bombardment time was 10 minutes; then, The target of the MEVVA source was replaced with a high-purity iron target, and the iron catalyst was deposited on the carbon nanotube film bombarded by silver ions. During the deposition, the sample stage was kept rotating at a constant speed, the sample stage bias was set to -200V, and the beam current ...

Embodiment 2

[0035] (1) Pretreatment of carbon nanotube film and deposition catalyst:

[0036] First cut the commercially available carbon nanotube film into small pieces of 2cm×2cm, and then use metal vapor vacuum arc ion source (MEVVA source) to bombard it with energy-carrying silver ions. The voltage was set to -10kV, the beam current was 5 mA, and the bombardment time was 10 minutes; then, the target of the MEVVA source was replaced with a high-purity iron target, and the iron catalyst was deposited on the carbon nanotube film bombarded by silver ions. , keeping the sample stage rotating at a constant speed, the sample stage bias voltage was set to -200V, the beam current was 5 mA, and the deposition time was 100 seconds.

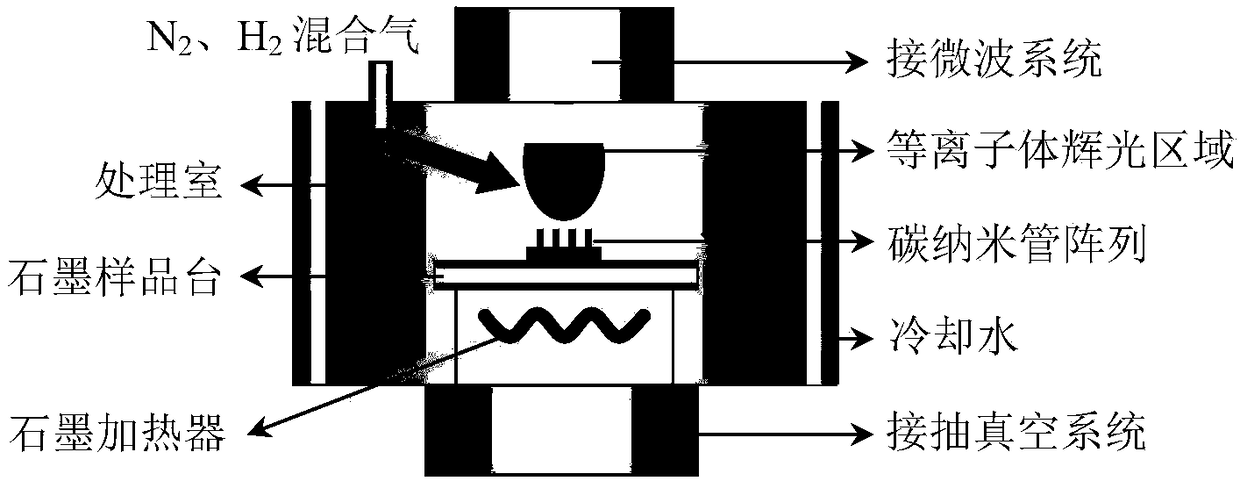

[0037] (2) Preparation of carbon nanotube arrays by thermal chemical vapor deposition and high temperature annealing treatment:

[0038] Put the carbon nanotube film deposited with iron catalyst obtained in step (1) into a high-temperature quartz tube furnace to pr...

Embodiment 3

[0044] (1) Pretreatment of carbon nanotube film and deposition catalyst:

[0045] First cut the commercially available carbon nanotube film into small pieces of 2cm×2cm, and then use metal vapor vacuum arc ion source (MEVVA source) to bombard it with energy-carrying silver ions. The voltage was set to -10kV, the beam current was 5 mA, and the bombardment time was 10 minutes; then, the target of the MEVVA source was replaced with a high-purity iron target, and the iron catalyst was deposited on the carbon nanotube film bombarded by silver ions. , keeping the sample stage rotating at a constant speed, the sample stage bias voltage was set to -200V, the beam current was 5 mA, and the deposition time was 100 seconds.

[0046] (2) Preparation of carbon nanotube arrays by thermal chemical vapor deposition and high temperature annealing treatment:

[0047] Put the carbon nanotube film deposited with iron catalyst obtained in step (1) into a high-temperature quartz tube furnace to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com