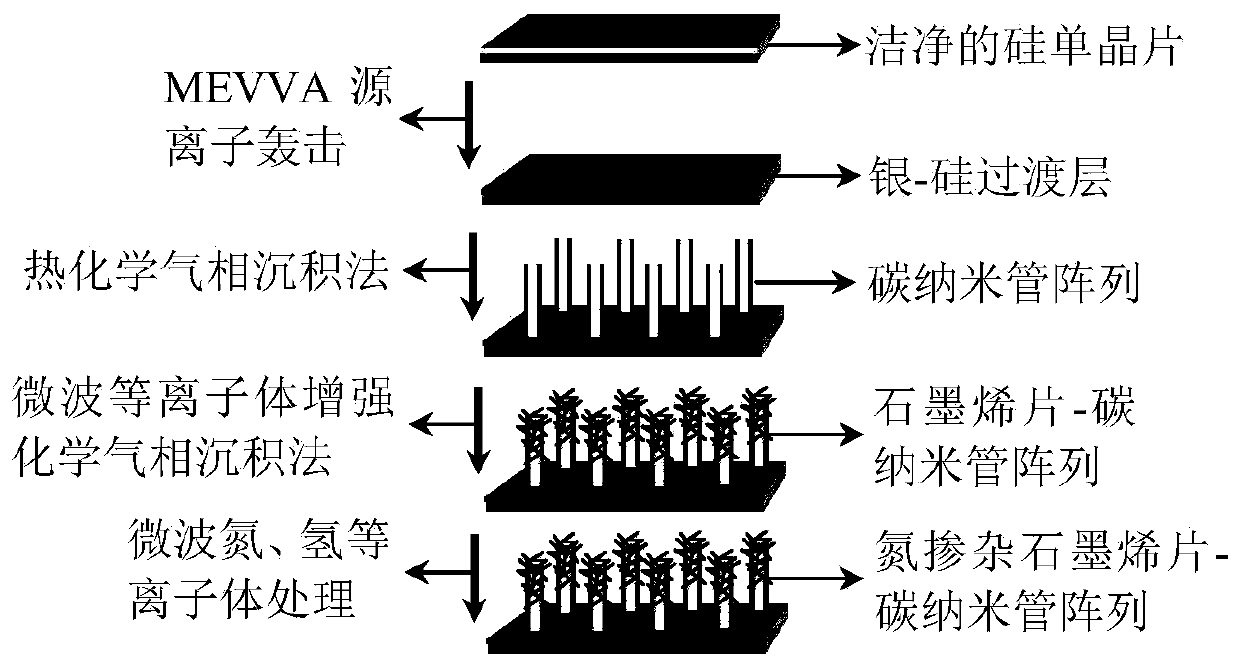

A method for improving the field emission performance of graphene sheet-carbon nanotube array composites

A carbon nanotube array and graphene sheet technology, which is applied in the preparation and application of nanomaterials, can solve the problems of large number of field emission points, poor stability, and low work function, and achieve the goal of increasing the maximum field emission current density, The effect of promoting the transport of electrons and reducing the work function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

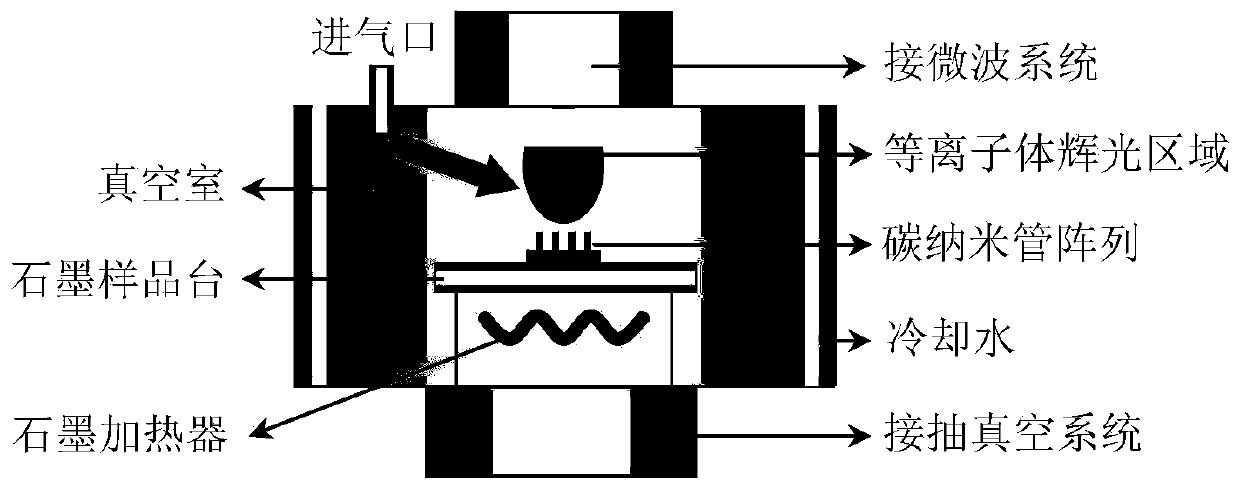

Method used

Image

Examples

Embodiment 1

[0027] (1) Pretreatment of silicon single wafer:

[0028] First cut the silicon single wafer into small pieces of 2cm×2cm, then ultrasonically (50W) clean them in deionized water and absolute ethanol for 5 minutes, and then immerse the silicon single wafer in 4% hydrofluoric acid by volume After 5 minutes, take it out and dry it, then carry out energy-carrying silver ion bombardment pretreatment in the silicon single wafer with clean surface obtained in a metal vapor vacuum arc ion source (MEVVA source), and keep the sample stage rotating at a constant speed during the bombardment , the sample stage bias voltage was set to -15kV, the beam current was 10 mA, and the bombardment time was 10 minutes.

[0029] (2) Preparation of carbon nanotube arrays by thermal chemical vapor deposition and high temperature annealing treatment:

[0030] Put the silicon single wafer that step (1) obtains into the magnetron sputtering device and deposit the iron catalyst film with a thickness of 5...

Embodiment 2

[0038] (1) Pretreatment of silicon single wafer:

[0039] First cut the silicon single wafer into small pieces of 2cm×2cm, then ultrasonically (50W) clean them in deionized water and absolute ethanol for 5 minutes, and then immerse the silicon single wafer in 4% hydrofluoric acid by volume After 5 minutes, take it out and dry it, then carry out energy-carrying silver ion bombardment pretreatment in the silicon single wafer with clean surface obtained in a metal vapor vacuum arc ion source (MEVVA source), and keep the sample stage rotating at a constant speed during the bombardment , the sample stage bias voltage was set to -15kV, the beam current was 10 mA, and the bombardment time was 10 minutes.

[0040] (2) Preparation of carbon nanotube arrays by thermal chemical vapor deposition and high temperature annealing treatment:

[0041] Put the silicon single wafer that step (1) obtains into the magnetron sputtering device and deposit the iron catalyst film with a thickness of 5...

Embodiment 3

[0049] (1) Pretreatment of silicon single wafer:

[0050] First cut the silicon single wafer into small pieces of 2cm×2cm, then ultrasonically (50W) clean them in deionized water and absolute ethanol for 5 minutes, and then immerse the silicon single wafer in 4% hydrofluoric acid by volume After 5 minutes, take it out and dry it, then carry out energy-carrying silver ion bombardment pretreatment in the silicon single wafer with clean surface obtained in a metal vapor vacuum arc ion source (MEVVA source), and keep the sample stage rotating at a constant speed during the bombardment , the sample stage bias voltage was set to -15kV, the beam current was 10 mA, and the bombardment time was 10 minutes.

[0051] (2) Preparation of carbon nanotube arrays by thermal chemical vapor deposition and high temperature annealing treatment:

[0052] Put the silicon single wafer that step (1) obtains into the magnetron sputtering device and deposit the iron catalyst film with a thickness of 5 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com