A hollow cup brushless motor protected by injection molding

A technology of brushless motors and coreless cups, applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems such as different, stator coil vibration, insulation failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The concrete implementation method of the present invention is as follows:

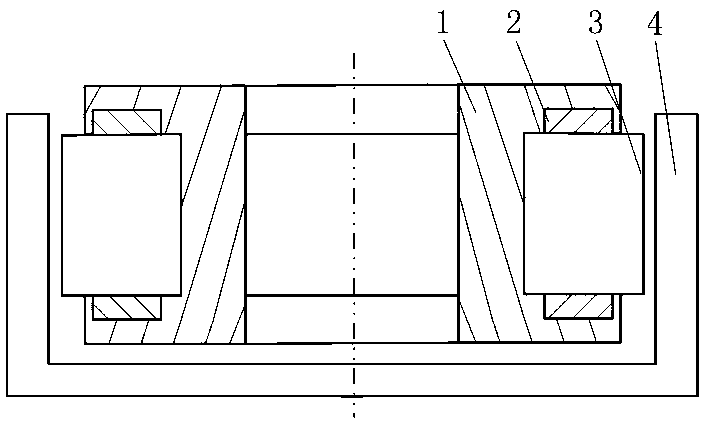

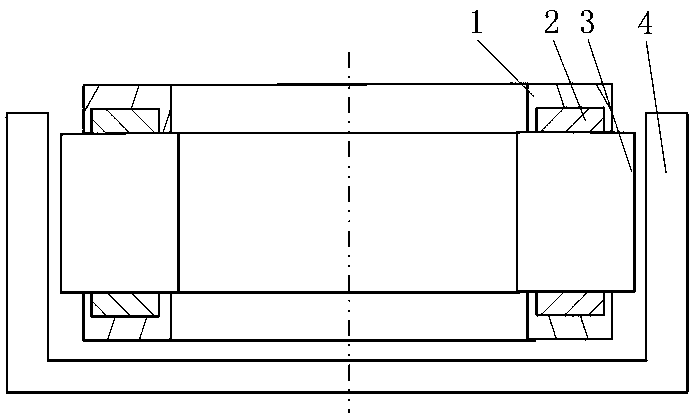

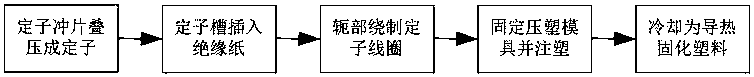

[0029] Such as figure 1 The first embodiment of the hollow cup brushless motor protected by injection molding of the present invention is shown. The hollow cup brushless motor protected by injection molding is composed of a cup-shaped outer rotor, an inner stator and a shaft. The stator punch of the inner stator has a prime number of aligned riveting holes. And use the rivet holes to rivet and assemble the stator core; the edge of the slot of the stator core is chamfered, then dipped in paint and dried.

[0030] The cup-shaped outer rotor is fixed on the shaft.

[0031] The enameled wire is wound around the stator teeth to form a stator coil. The distance between the stator coil and the outer circle of the stator is 3mm-5mm, and the winding directions of adjacent stator coils are opposite.

[0032] The cross-section of the enameled wire is rectangular, and the enameled wire is formed into a U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com