Cutting machining device and method for CFRP special-shaped holes

A technology of cutting and special-shaped holes, which is applied in the field of mechanical cutting, can solve the problems of unsuitable preparation of CFRP special-shaped holes, triangular burrs, tearing and delamination damage, etc., and achieves strong implementability and good hole wall quality , high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

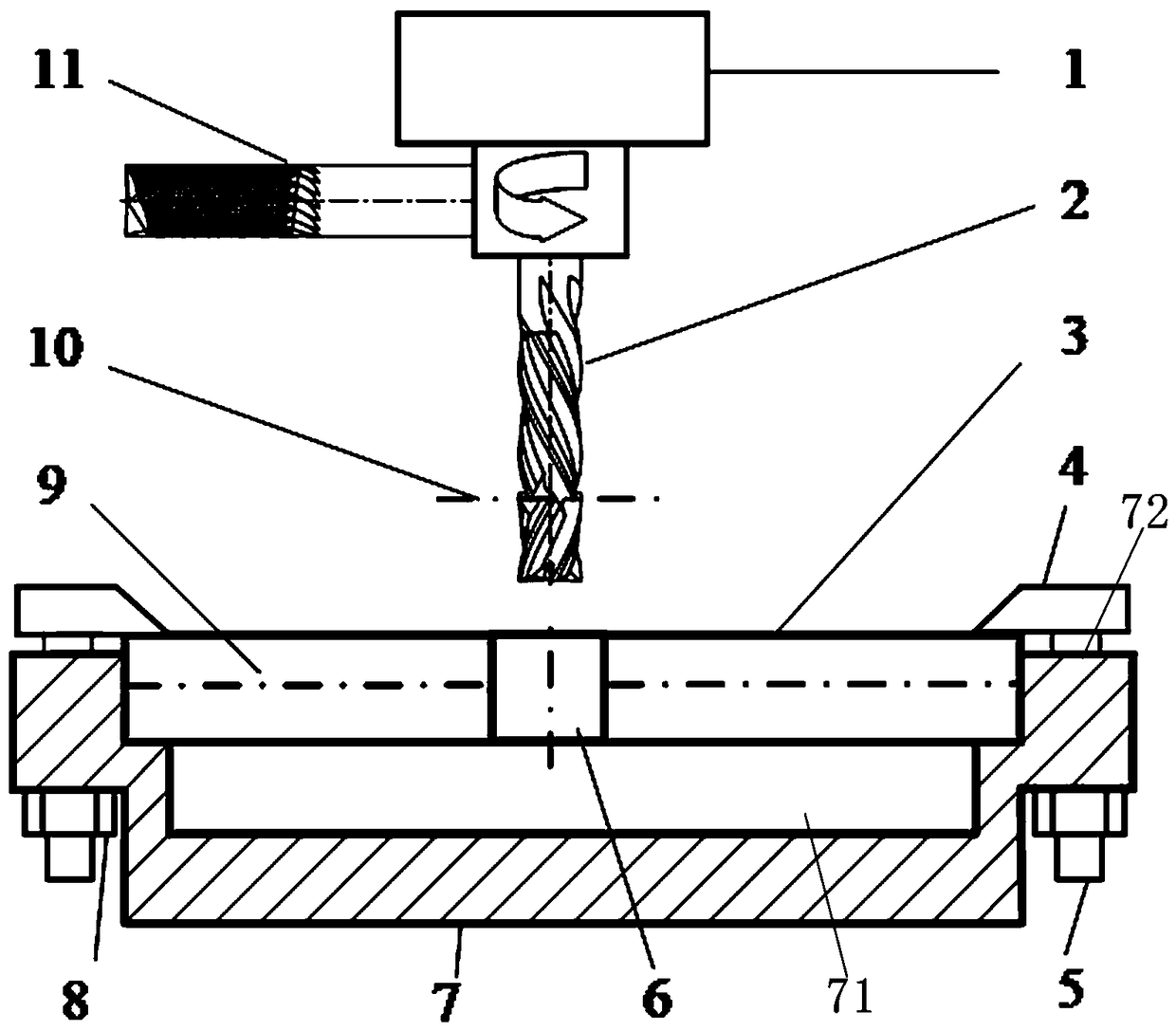

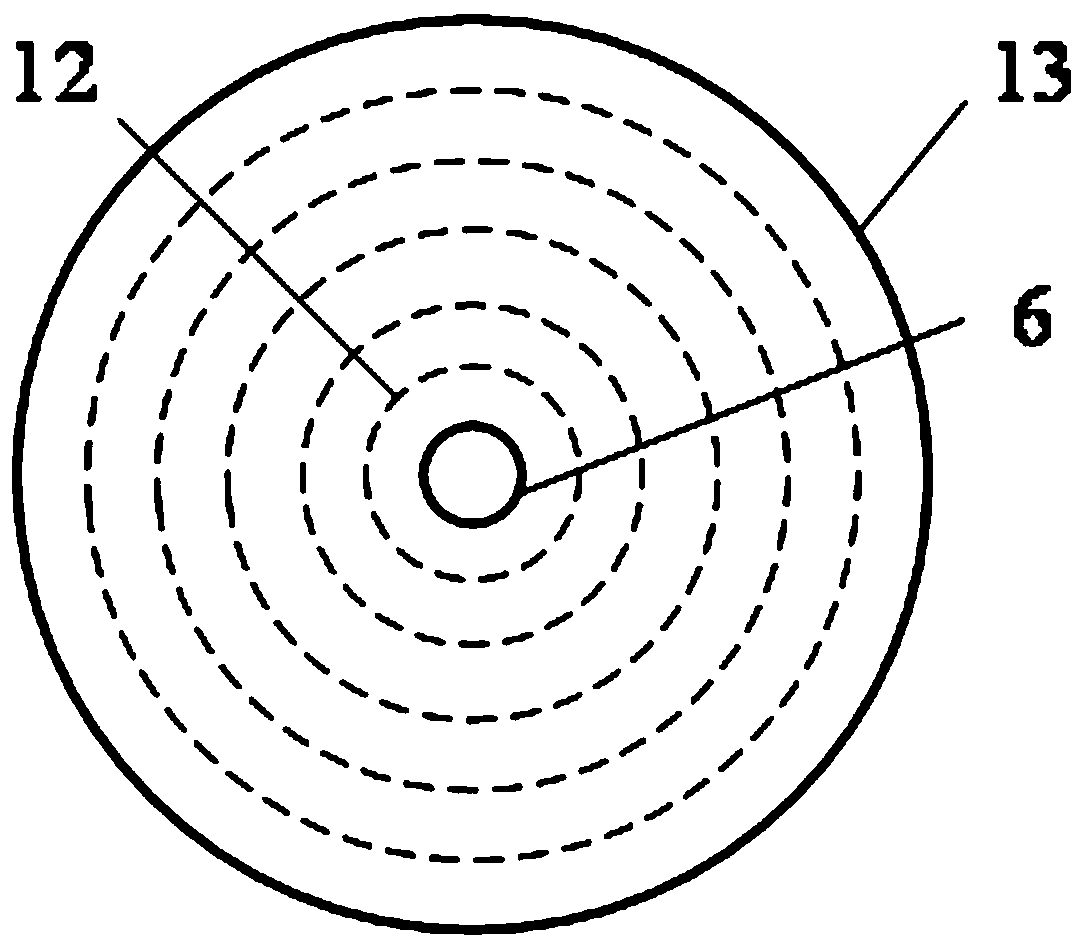

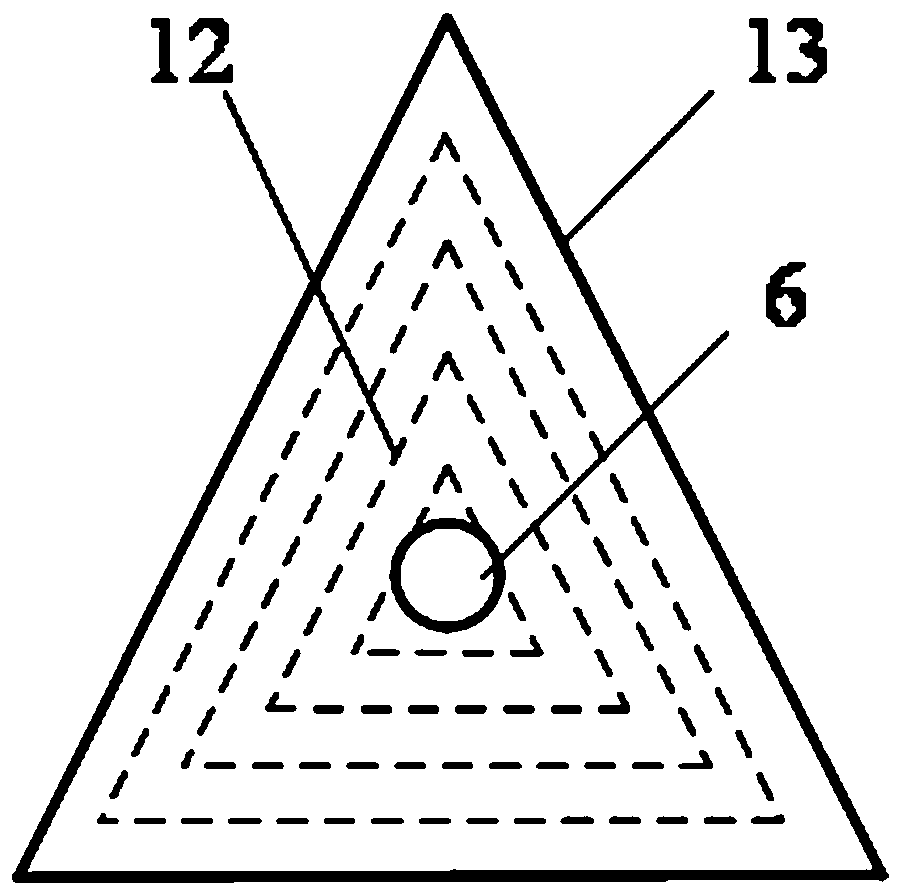

[0031] The brand for the fuselage of the C919 large passenger aircraft independently developed and produced by COMAC is T700 / LT-03A, and the carbon fiber direction [0 / + / 90 / - / 0 / 0 / + / 90 / - / 0 / 0 / - / 90 / + / 0 / 0 / - / 90 / + / 0]s Lay 40 layers of 5mm thick CFRP laminates, apply the method of the present invention, prepare large-diameter circular, triangular, rectangular and trapezoidal special-shaped holes, such as Figure 1 to Figure 5 As shown, a CFRP special-shaped hole 13 cutting processing device of the present invention includes a clamp body 7, the top of the clamp body 7 is provided with a processing groove 71 downward, and both ends of the clamp body 7 are provided with stepped surfaces 72, the top surface of the step surface 72 is provided with a pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com