Novel automatic anode plate brushing machine

An anode plate and automatic brushing technology, which is applied in the direction of grinding slide plate, grinding frame, grinding drive device, etc., can solve the problems of large plate anode slime and calcium and magnesium crystals that are difficult to handle, and achieve low cost and high work efficiency High, improve the effect of precipitation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

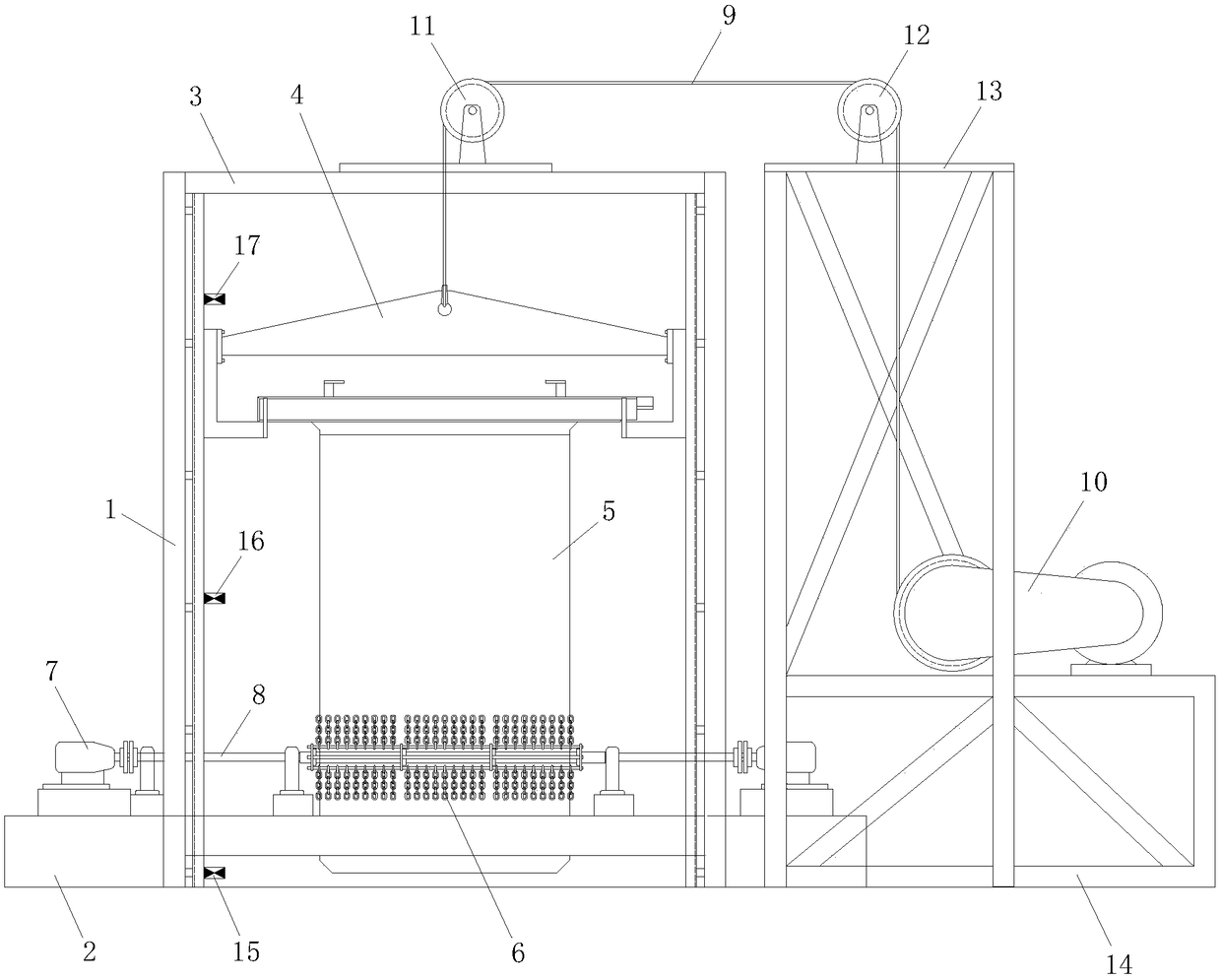

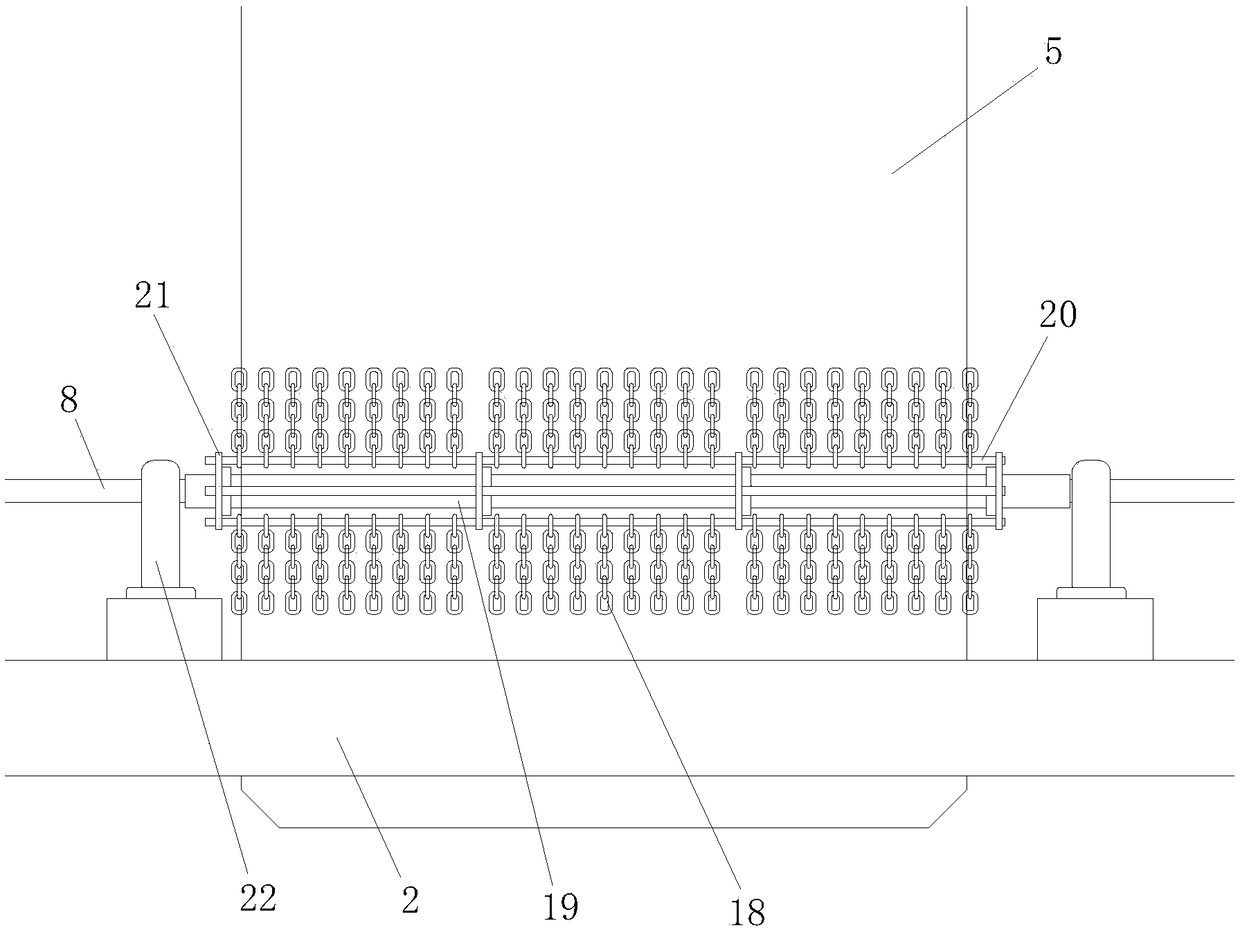

[0017] In this example, refer to figure 1 and figure 2 , the novel anode plate automatic brushing machine includes a PLC controller, a frequency converter, a power unit, an anode hanger 4 and a stand 1, the PLC controller and the frequency converter are connected to the power unit, and a PLC control system is used to realize automatic plate brushing , the power unit is connected to the anode hanger 4, the anode hanger 4 is installed on the stand 1 to form a liftable structure, the anode plate 5 is installed on the anode hanger 4; it also includes a brush plate mechanism 6, and the brush plate mechanism 6 is close to the anode plate 5, and close to the electrolysis area at the bottom of the anode plate 5, so as to remove the anode slime and calcium and magnesium crystals; The plates 5 are arranged in parallel, the brush shaft 19 is connected to the motor 7 through the transmission shaft 8, and the rotation of the brush shaft 19 drives the brush chain 18 to perform centrifugal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com