Preparation process of fireproof door

A preparation process and technology for fire doors, applied in the direction of manufacturing tools, wood processing appliances, and jointing of wooden veneers, can solve the problems of filling gaps or dead corners, insufficient drying process, uneven filling of fire doors, etc., to achieve High production efficiency, simple preparation method, good sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

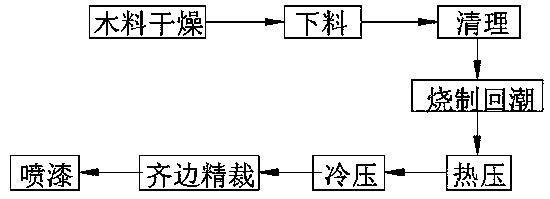

Image

Examples

Embodiment 1

[0027] Embodiment 1, the existing solid wood door preparation process, comprises the following steps:

[0028] (1) Drying of wood: Put the board into the drying kiln for spray steaming and drying to obtain the rough material;

[0029] (2) Blanking: process the rough material into the specified dimensions, and ensure the consistency;

[0030] (3) Cleaning: wash off the sawdust, dust and other impurities on the surface of the blank with clean water;

[0031] (4) Hot pressing: Set the hot pressing temperature and pressure, and slowly put the solid wood door blank into the hot press machine. fill all positions;

[0032] (5) Cold pressing: first clean up the sundries on the press and put a light sheet on it, measure with a ruler to ensure that the thickness of the solid wood door blank after hot pressing is consistent, and then send it into the cold press;

[0033] (6) Edge trimming: Cut the cold-pressed solid wood door blank material, the cutting error does not exceed 0.2MM cut...

Embodiment 2

[0034] Embodiment 2, a kind of preparation technology of fire door, comprises the following steps:

[0035] (1) Drying of wood: select solid wood boards, put them into a drying kiln for spray steaming and drying, and obtain blanks. The time for spraying and steaming of the boards is 15 minutes, and the time for heating and drying is 25 days;

[0036] (2) Cutting: process the rough material into the specified shape and size, and ensure the consistency, and cut the glass fiber fireproof cloth into the same shape and size as the rough material;

[0037] (3) Cleaning: wash off the sawdust, dust and other impurities on the surface of the blank with clean water;

[0038] (4) Firing and regaining moisture: put the cleaned blanks into the kiln for firing, and leave the kiln after the temperature difference between the inside and outside of the kiln is less than 15°C, stack them neatly and perform natural moisture regaining treatment for 30 days to obtain solid wood door blanks;

[00...

Embodiment 3

[0043] Embodiment 3, a kind of preparation technology of fire door, comprises the following steps:

[0044] (1) Drying of wood: select solid wood boards, put them into a drying kiln for spray steaming and drying, and obtain blanks. The time for spray steaming of the boards is 15 minutes, and the time for heating and drying is 28 days;

[0045] (2) Cutting: process the rough material into the specified shape and size, and ensure the consistency, and cut the glass fiber fireproof cloth into the same shape and size as the rough material;

[0046] (3) Cleaning: wash off the sawdust, dust and other impurities on the surface of the blank with clean water;

[0047] (4) Firing and regaining moisture: put the cleaned blanks into the kiln for firing, and leave the kiln after the temperature difference between the inside and outside of the kiln is less than 15°C, stack them neatly and perform natural moisture regaining treatment for 30 days to obtain solid wood door blanks;

[0048] (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com