Sound-absorbing felt

A sound-absorbing and sound-absorbing layer technology, used in building components, sound insulation, layered products, etc., can solve the problems of poor low-frequency sound absorption effect, and achieve good sound absorption effect, good fire resistance and flame retardancy, and flexible fibers. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

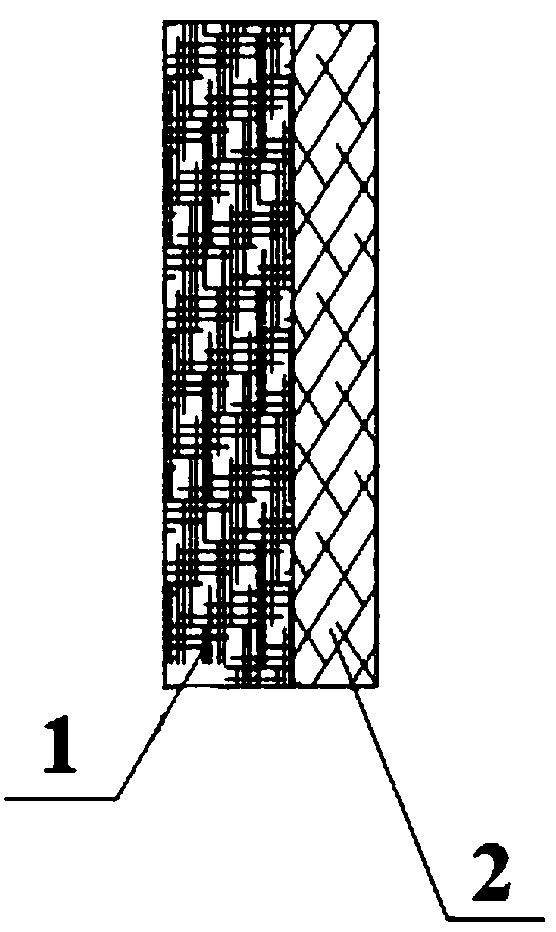

Image

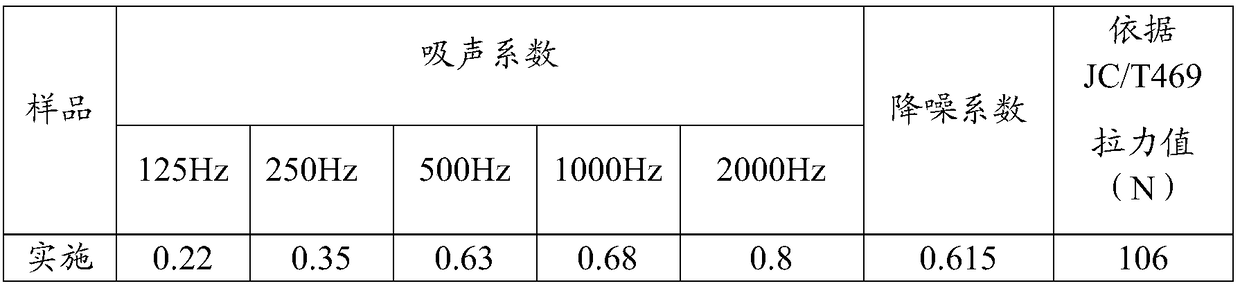

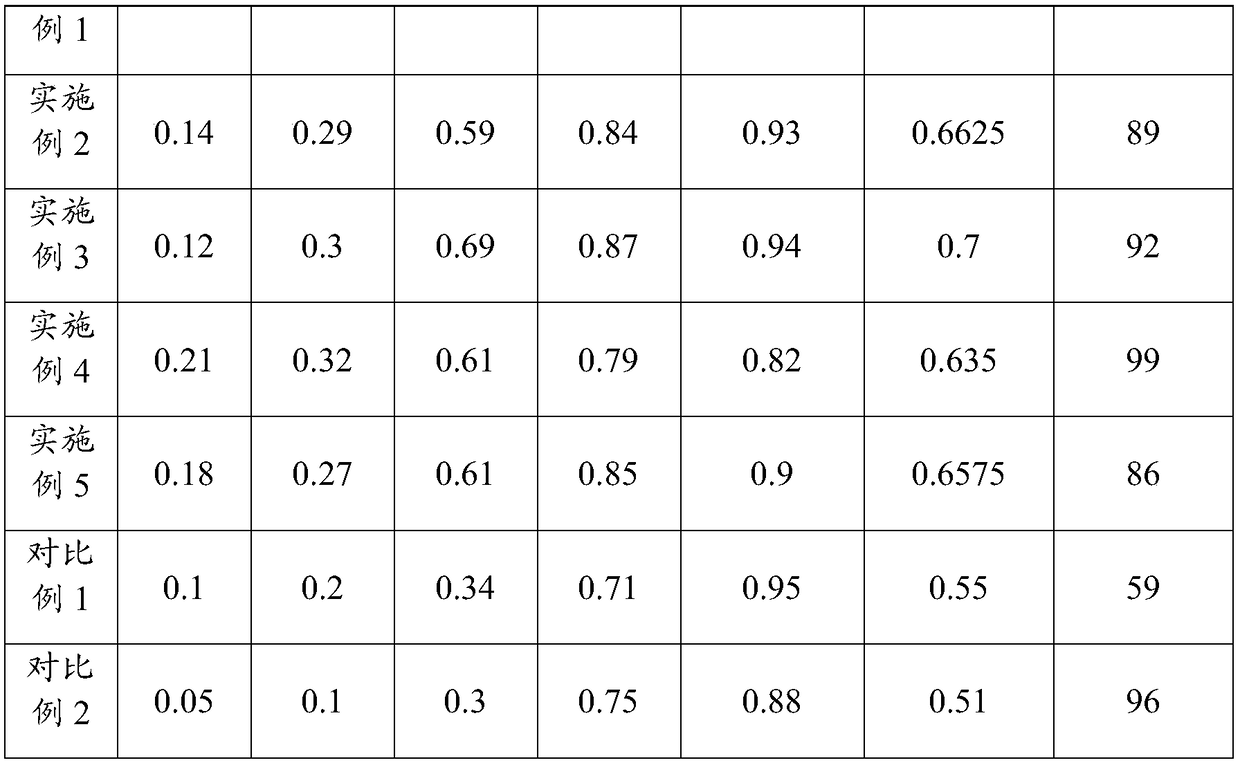

Examples

Embodiment 1

[0031] This embodiment provides a sound-absorbing felt, which is composed of a first sound-absorbing layer and a second sound-absorbing layer arranged in layers. The first sound-absorbing layer is obtained by using polyacrylonitrile pre-oxygen fiber through acupuncture process, and the surface density is 5kg / m 2 , the thickness is 1cm; the second sound-absorbing layer is also obtained by acupuncture process with polyacrylonitrile pre-oxygen fiber, and the surface density is 1.5kg / m 2 , thickness 4cm.

[0032] During acupuncture, the barbed hook on the needle drives the fibers on the surface and subsurface of the main layer of the polyacrylonitrile pre-oxidized fiber to move from the plane direction of the main layer to the vertical direction, so that the fibers are displaced up and down and the extension direction changes. , forming a polyacrylonitrile pre-oxygen fiber cluster with an extension direction of 85-95° to the main layer.

[0033] The polyacrylonitrile pre-oxygen f...

Embodiment 2

[0036] This embodiment provides a sound-absorbing felt, which is composed of a first sound-absorbing layer and a second sound-absorbing layer arranged in layers. The first sound-absorbing layer is obtained by using polyacrylonitrile pre-oxygen fiber through acupuncture process, and the surface density is 2kg / m 2 , the thickness is 2cm; the second sound-absorbing layer is also obtained by acupuncture process with polyacrylonitrile pre-oxygen fiber, and the surface density is 3kg / m 2 , thickness 3cm.

[0037] The polyacrylonitrile pre-oxygen fiber used in this embodiment has a length ranging from 6 to 12 cm and a diameter of 11 to 20 μm.

[0038] In use, the first sound-absorbing layer faces the sound source as the side close to the sound source, and the second sound-absorbing layer is the side away from the sound source.

Embodiment 3

[0040] This embodiment provides a sound-absorbing felt, which is composed of a first sound-absorbing layer and a second sound-absorbing layer arranged in layers. The first sound-absorbing layer is obtained by using polyacrylonitrile pre-oxygen fiber through acupuncture process, and the surface density is 1.5kg / m 2 , the thickness is 3cm; the second sound-absorbing layer is also obtained by acupuncture process with polyacrylonitrile pre-oxygen fiber, and the surface density is 4kg / m 2 , thickness 2cm.

[0041] During acupuncture, the barbed hook on the needle drives the fibers on the surface and subsurface of the main layer of the polyacrylonitrile pre-oxidized fiber to move from the plane direction of the main layer to the vertical direction, so that the fibers are displaced up and down and the extension direction changes. , forming a polyacrylonitrile pre-oxygen fiber cluster with an extension direction of 85-95° to the main layer.

[0042] The polyacrylonitrile pre-oxygen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com