Small short-cut nitrification and denitrification device for treating livestock and poultry breeding wastewater and method

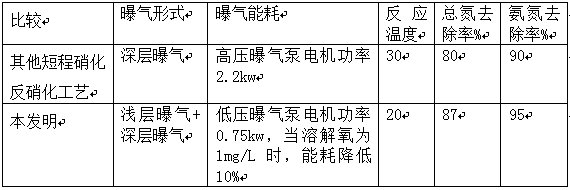

A technology for livestock and poultry breeding wastewater and short-range nitrification, which is applied to the field of small-scale short-range nitrification and denitrification devices, can solve problems such as unrealistic heating, and achieve the effects of avoiding energy consumption increase, reducing aeration energy consumption, and avoiding reaction time increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

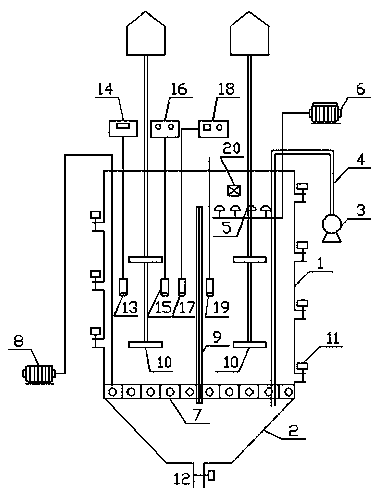

[0041] A short-range nitrification and denitrification small-scale device for treating livestock and poultry breeding wastewater, the device includes a column reactor, an aeration system, a water inlet system, a drainage system, a stirring system, an online monitoring system, a temperature control system, an automatic control system, and a complete set of devices It is fixed by a stainless steel frame; it is characterized by:

[0042] The columnar reactor refers to: the reactor main body 1 of the cylinder is placed vertically, the lower end is connected with a conical mud bucket 2 of the same diameter, the slope of the side wall of the mud bucket is i=1:2, and the upper end of the cylinder is set with the same material The top cover, the top cover has 9 holes, the temperature sensor 19, the heater 20, the stirring shaft 10 of the two stirrers, the dissolved oxygen sensor 13, the pH sensor 15, the redox potential sensor 17, the air pipe, and the water inlet pipe 4 are all compos...

Embodiment 2

[0045] A short-range nitrification and denitrification small-scale device for treating livestock and poultry wastewater, including a column reactor, an aeration system, a water inlet system, a drainage system, a mixing system, an online monitoring system, a temperature control system, and an automatic control system. The entire device is made of stainless steel Stand up and fix:

[0046] The columnar reactor refers to: the reactor main body 1 of the cylinder is placed vertically, the lower end is connected with a conical mud bucket 2 of the same diameter, the slope of the side wall of the mud bucket is i=1:2, and the upper end of the cylinder is set with the same material Top cover, top cover with 9 holes, temperature sensor 19, heater 20, stirring shaft 10 of 2 stirrers, dissolved oxygen sensor 13, pH sensor 15, redox potential sensor 1), air pipe, water inlet pipe 4 all Through the hole in the top cover and into the main body of the reactor, the vertical rod is welded and fi...

Embodiment 3

[0055] How to run:

[0056] (1) System startup method (also called sludge domestication method)

[0057] Periodic operation is adopted, and each cycle includes water intake→aeration→sedimentation→drainage→idle.

[0058] 1) Pretreat livestock and poultry breeding wastewater so that CODcr is less than 2000mg / L, and adjust the carbon-nitrogen ratio (C / N) to no more than 6.8;

[0059] 2) Set the temperature on the PLC to a constant temperature of 20°C, DO is about 2.0mg / L, adopt the deep aeration method, inoculate the complete nitrification sludge of domestic sewage, the sludge amount is 3000mg / L, and feed water for 20 minutes every cycle→exposure Gas for 8 hours → sediment for 1 hour → drain for 1 hour → idle for 100 minutes, run 2 cycles a day for 30 days. During operation, the proportion of nitrite nitrogen (NO- 2-N / NO-x-N) ranged from 25.4% to 42.8% and gradually decreased with time, and the concentration of NO- 2-N was always lower than that of NO- 3-N.

[0060] 3) Continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com