A kind of preparation method of L-glutamine

A glutamine and crystallization technology, applied in the field of amino acid production, can solve the problems of large acid and alkali, high production cost, environmental pollution and the like, and achieve the effects of improving yield, reducing pollution and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

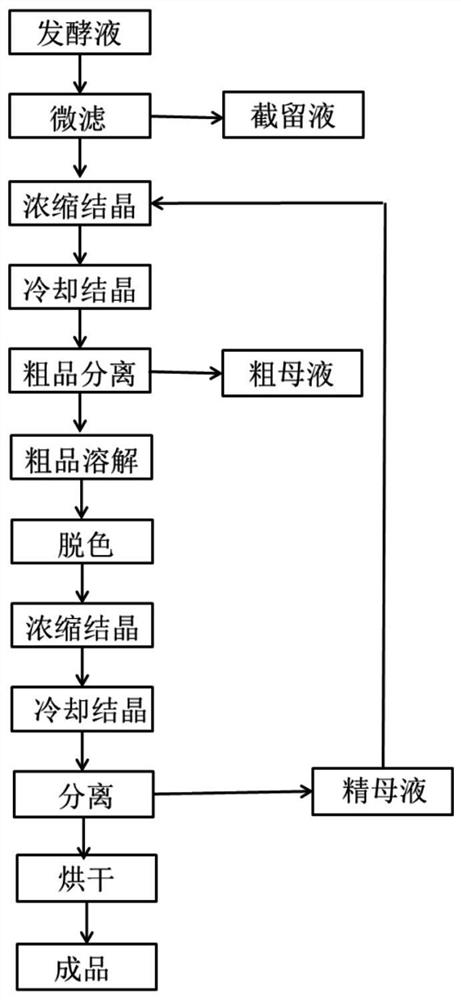

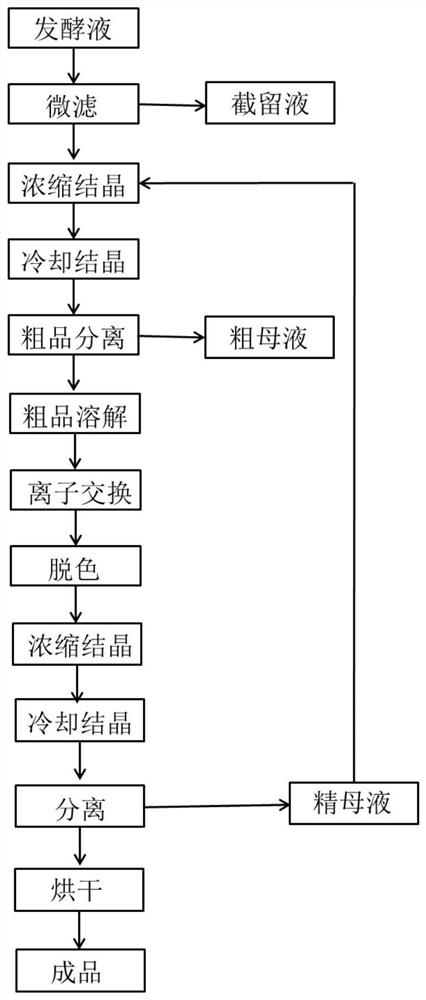

Method used

Image

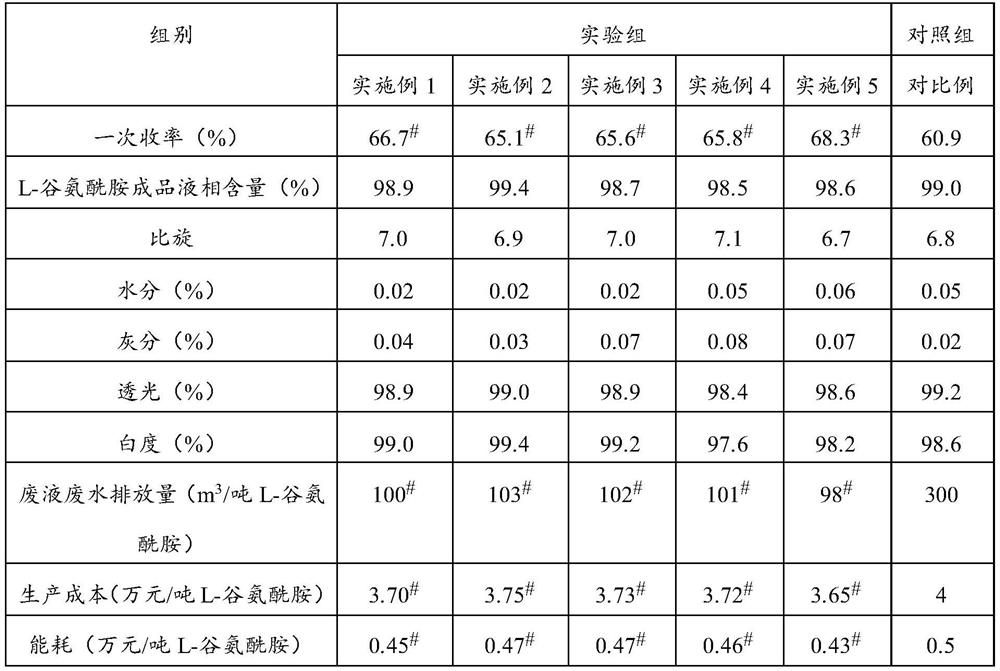

Examples

preparation example Construction

[0024] The invention discloses a preparation method of L-glutamine, and those skilled in the art can refer to the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

[0025] The invention provides a method for extracting glutamine from fermented liquid. The extraction process of twice crystallization and one decolorization adopted in the invention has the advantages of ...

Embodiment 1

[0041] Embodiment 1 extracts L-glutamine from fermented liquid

[0042] Take 30L of fermentation broth, the fermentation broth produces 85g / L of acid, use 150kda ceramic membrane microfiltration, the temperature is 42°C, the transmembrane pressure difference is 2.0bar, the concentration factor is 10 times, and the filtrate is concentrated and crystallized to glutamine The mass percentage of L-glutamine is 25%; cooled to 5° C., pre-crystallized for 10 hours, and the crude product of L-glutamine is separated and obtained, the crude product is 3250 g, and the moisture content of the crude product is 32%.

[0043] Add deionized water, make 43L of L-glutamine 5.0% crude product solution at 40°C, add 215g medicinal carbon for decolorization and stir for 30min to obtain decolorized clear night; The mass percentage of aminoamide is 30%; the temperature is lowered by 10°C every hour to 8°C for separation, and the wet product is dried to obtain 1700g of L-glutamine finished product.

[0...

Embodiment 2

[0045] Embodiment 2 extracts L-glutamine from fermented liquid

[0046] Take 20L of fermentation broth, acid production of fermentation broth is 83g / L, using 150kda ceramic membrane microfiltration, the temperature is 35°C, the transmembrane pressure difference is 3.6bar, and the concentration factor is 8 times, and the filtrate is concentrated and crystallized, and concentrated to glutamine The mass percentage of L-glutamine was 24%; cooled to 5° C., pre-crystallized for 10 hours, and the crude product of L-glutamine was separated, 2120 g of the crude product, and 33% of the moisture content of the crude product.

[0047] Add deionized water, make 30.6L of L-glutamine 4.5% crude product solution at 35°C, add 125g of medical carbon for decolorization and stir for 30min to obtain decolorized clear night, the decolorization solution is concentrated and crystallized, the evaporation temperature is ≦40°C, and concentrated to The mass percentage of glutamine is 28%; the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com