Three-layer efficient bonded PVC (Polyvinyl Chloride) tube extrusion preparation method

A technology of PVC pipe and PVC resin, applied in the direction of tubular articles, applications, household appliances, etc., to achieve the effect of high tensile strength, convenient construction and excellent chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

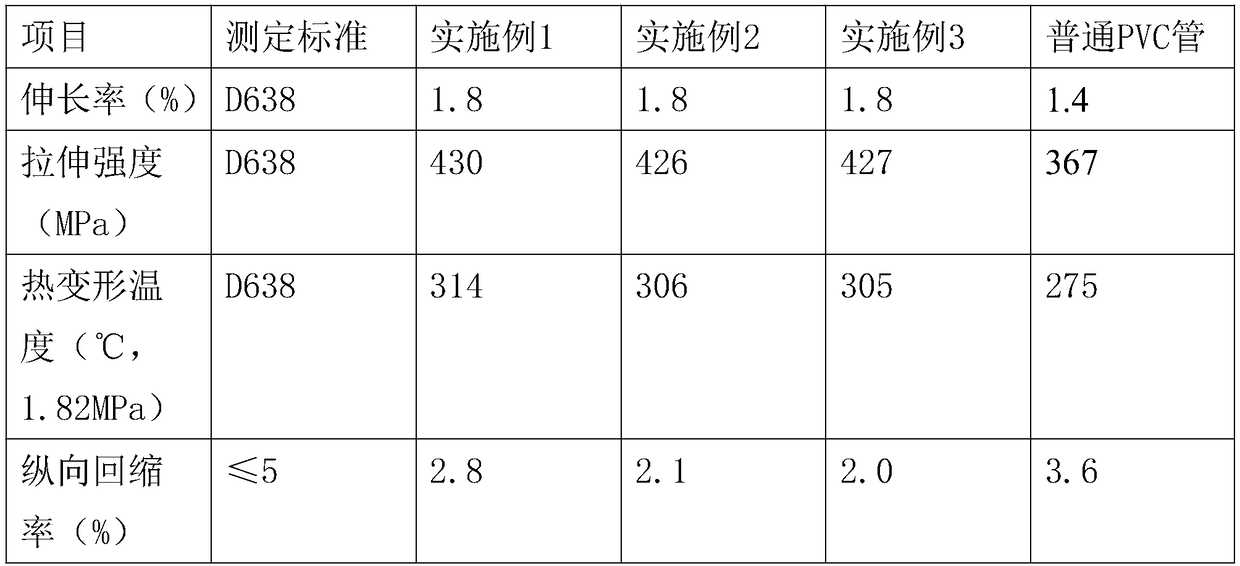

Examples

Embodiment 1

[0032] A three-layer high-efficiency bonded PVC pipe extrusion preparation method, the multi-layer PVC pipe includes an upper PVC resin layer, a middle grid-like reinforcement layer and a lower plastic film layer arranged in sequence;

[0033] The upper PVC resin layer is prepared from the following components in parts by weight: 140 parts of PVC, 0.5 parts of pearl micropowder, 8 parts of barium sulfate, 2 parts of stabilizer, 1 part of external lubricant, and 0.6 part of toughening agent;

[0034] The middle grid reinforcement layer adopts a grid reinforcement layer composed of warp threads and weft threads, and the weft threads are formed by combining and twisting at least one aramid fiber and at least one polyester fiber; the warp threads are made of short cotton linters Twisted with thermoplastic resin;

[0035] The lower plastic film layer is made of the following raw materials in parts by mass: 60 parts of polyvinyl alcohol, 15 parts of artemisia gum, 12 parts of hydrox...

Embodiment 2

[0053] Embodiment 2: three-layer high-efficiency bonded PVC pipe extrusion preparation method: the multilayer PVC pipe includes an upper PVC resin layer, a middle grid-like reinforcement layer and a lower plastic film layer arranged in sequence;

[0054] The upper PVC resin layer comprises the following components in parts by weight: 1160 parts of PVC, 1 part of pearl micropowder, 9 parts of barium sulfate, 3 parts of stabilizer, 2 parts of external lubricant, and 1.5 parts of toughening agent;

[0055] The middle grid reinforcement layer adopts a grid reinforcement layer composed of warp threads and weft threads, and the weft threads are formed by combining and twisting at least one aramid fiber and at least one polyester fiber; the warp threads are made of short cotton linters Twisted with thermoplastic resin;

[0056] The lower plastic film layer is made of the following raw materials in parts by mass: 70 parts of polyvinyl alcohol, 20 parts of artemisia gum, 18 parts of hy...

Embodiment 3

[0074] Embodiment 3: Three-layer high-efficiency bonded PVC pipe extrusion preparation method, the multilayer PVC pipe includes an upper PVC resin layer, a middle grid-shaped reinforcing layer and a lower plastic film layer arranged in sequence;

[0075] The upper PVC resin layer comprises the following components by weight: 1:50 parts of PVC, 0.7 parts of pearl micropowder, 8.5 parts of barium sulfate, 2.5 parts of stabilizer, 1.5 parts of external lubricant, and 1 part of toughening agent;

[0076] The middle grid reinforcement layer adopts a grid reinforcement layer composed of warp threads and weft threads, and the weft threads are formed by combining and twisting at least one aramid fiber and at least one polyester fiber; the warp threads are made of short cotton linters Twisted with thermoplastic resin;

[0077] The lower plastic film layer is made of the following raw materials in parts by mass: 65 parts of polyvinyl alcohol, 17 parts of artemisia gum, 15 parts of hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Heat distortion temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com