Biomass fuel and preparation method thereof

A biomass fuel and raw material technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problems of low combustion calorific value, environmental protection not up to standard, insufficient combustion, etc., achieve low energy consumption, not easy to scatter, and good molding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

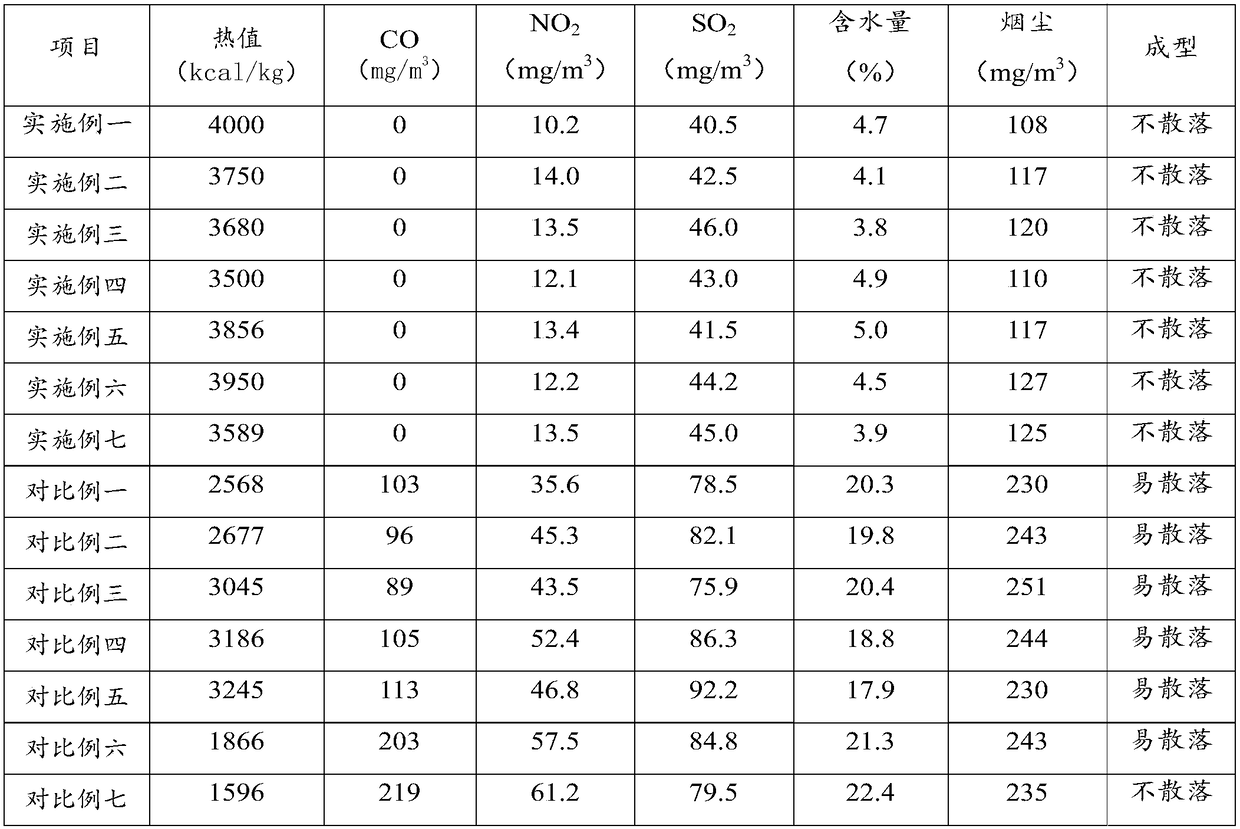

Examples

preparation example Construction

[0057] According to the second aspect of the present invention, the present invention provides a method for preparing biomass fuel, comprising the following steps: mixing crushed straw, sawdust and fallen leaves with sludge and edible fungus residue, and drying to obtain biomass fuel.

[0058] The preparation method of biomass fuel provided by the invention has easy-to-obtain raw materials from waste, low cost, simple preparation method, easy control of operating parameters, low energy consumption, good molding effect of the prepared biomass fuel, and is not easy scattered.

[0059] In a preferred embodiment, molding is carried out at 25-27°C after said drying step to obtain biomass fuel.

[0060] Wherein, the molding temperature may be, for example, but not limited to 25°C, 26°C or 27°C.

[0061] The molding temperature affects the molding effect of the biomass fuel. The molding temperature is controlled at a suitable temperature. The molding effect of the biomass fuel is g...

Embodiment 1

[0071] This embodiment provides a kind of biomass fuel, comprising the following raw material components in parts by weight: 50 parts of rice straw, 50 parts of wheat straw, 30 parts of corn straw, 30 parts of apple tree chips, 30 parts of pear tree chips, apple tree chips 60 parts of fallen leaves, 25 parts of swamp sludge and 13 parts of edible fungus residue.

[0072] Among them, the water content of rice straw is 5%, the water content of wheat straw is 5%, the water content of corn straw is 5%, the water content of apple wood chips is 5%, the water content of pear wood chips is 5%, and the water content of swamp sludge 30%.

Embodiment 2

[0074] This embodiment provides a kind of biomass fuel, including the following raw material components in parts by weight: 40 parts of rice straw, 40 parts of wheat straw, 40 parts of corn straw, 40 parts of apple tree chips, 35 parts of pear tree chips, apple tree chips 75 parts of fallen leaves, 20 parts of swamp sludge and 11 parts of edible fungus residue.

[0075] Among them, the water content of rice straw is 2%, that of wheat straw is 7%, that of corn straw is 7%, that of apple wood chips is 2%, that of pear wood chips is 7%, and that of swamp sludge 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com