Straw papermaking process

A technology of papermaking technology and straw, which is applied in the field of straw papermaking technology, can solve the problem of low concentration of straw pulp, and achieve the effect of high concentration, less slag and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

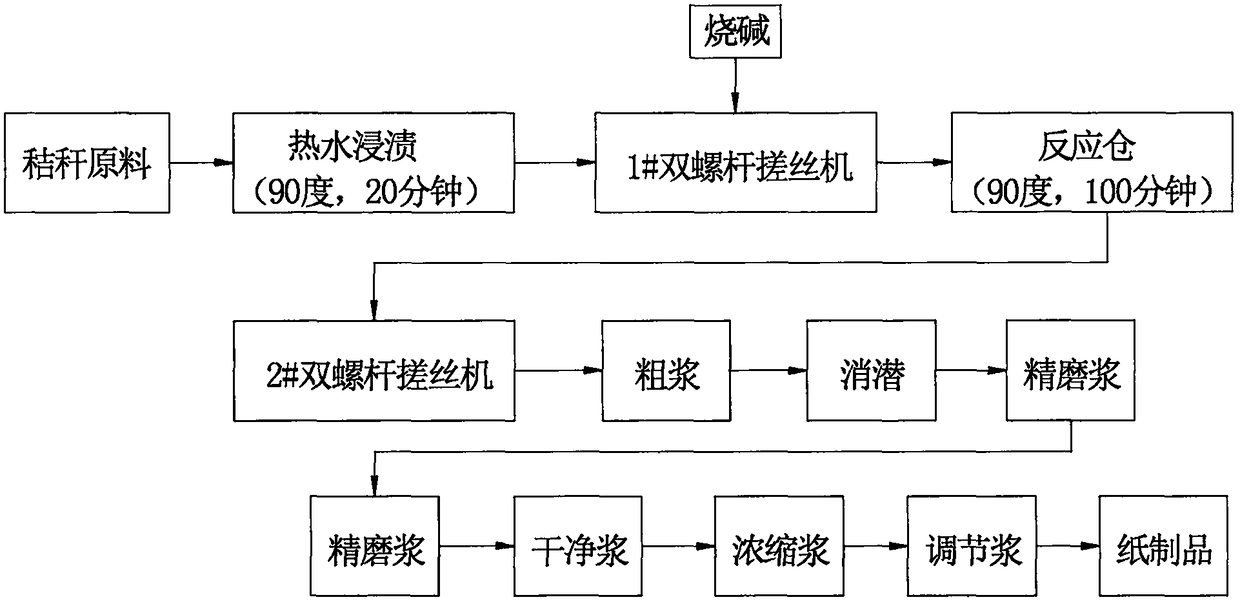

[0020] Embodiment one: if figure 1 As shown, the straw papermaking process comprises the following steps:

[0021] (1) Soak the straw in 90-degree hot water for 20 minutes to soften the straw;

[0022] (2) Pour the softened stalk into the twin-screw thread rolling machine to extrude the filaments, and pour caustic soda into the twin-screw thread rolling machine, and the caustic soda quality is 4% of the straw quality;

[0023] (3) Pour the material extruded by the twin-screw thread rolling machine into a reaction chamber with a temperature of 90 degrees to carry out hydrogen peroxide bleaching reaction treatment for 100 minutes;

[0024] (4) Pour out the material in the reaction chamber and pour it into another twin-screw thread rolling machine to extrude the divided wire again;

[0025] (5) Pour the extruded material into a refiner and grind it into a slurry to obtain a coarse slurry;

[0026] (6) Pour the coarse pulp into a fiber descrambler with a temperature of 60 degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com