Grating preparation on-line monitoring method and system

A grating and grating array technology, applied in the field of fiber grating sensing, can solve the problem of poor grating writing quality and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below with specific embodiments in combination with the drawings:

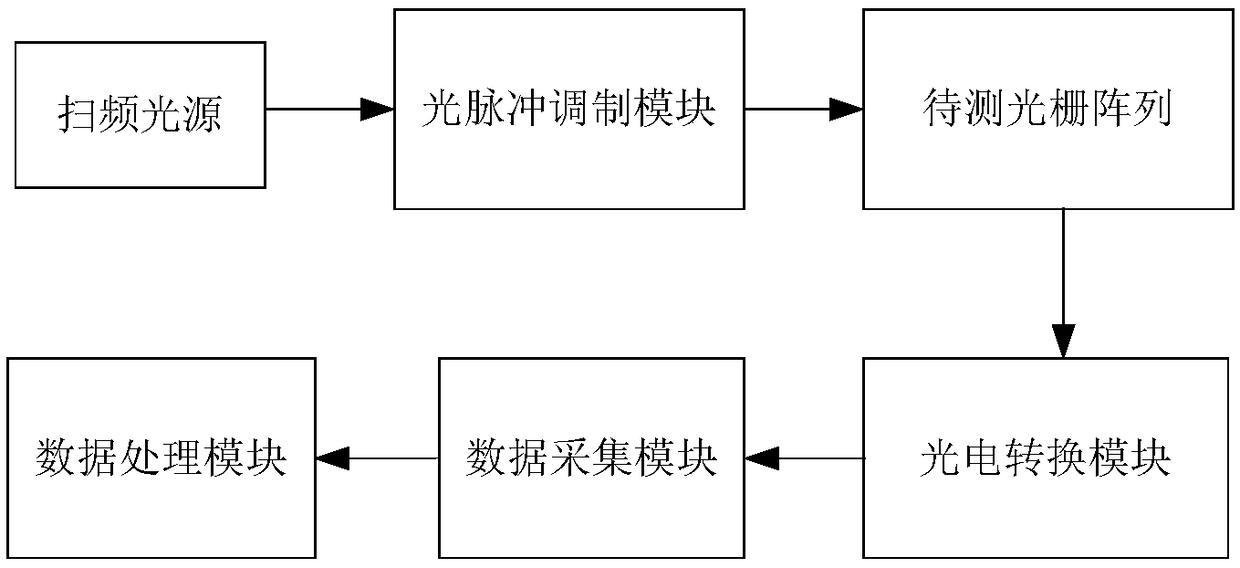

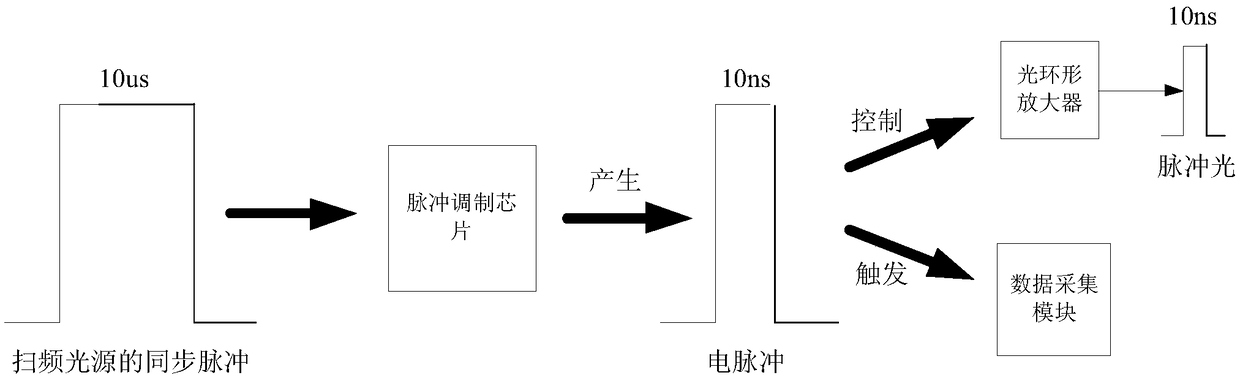

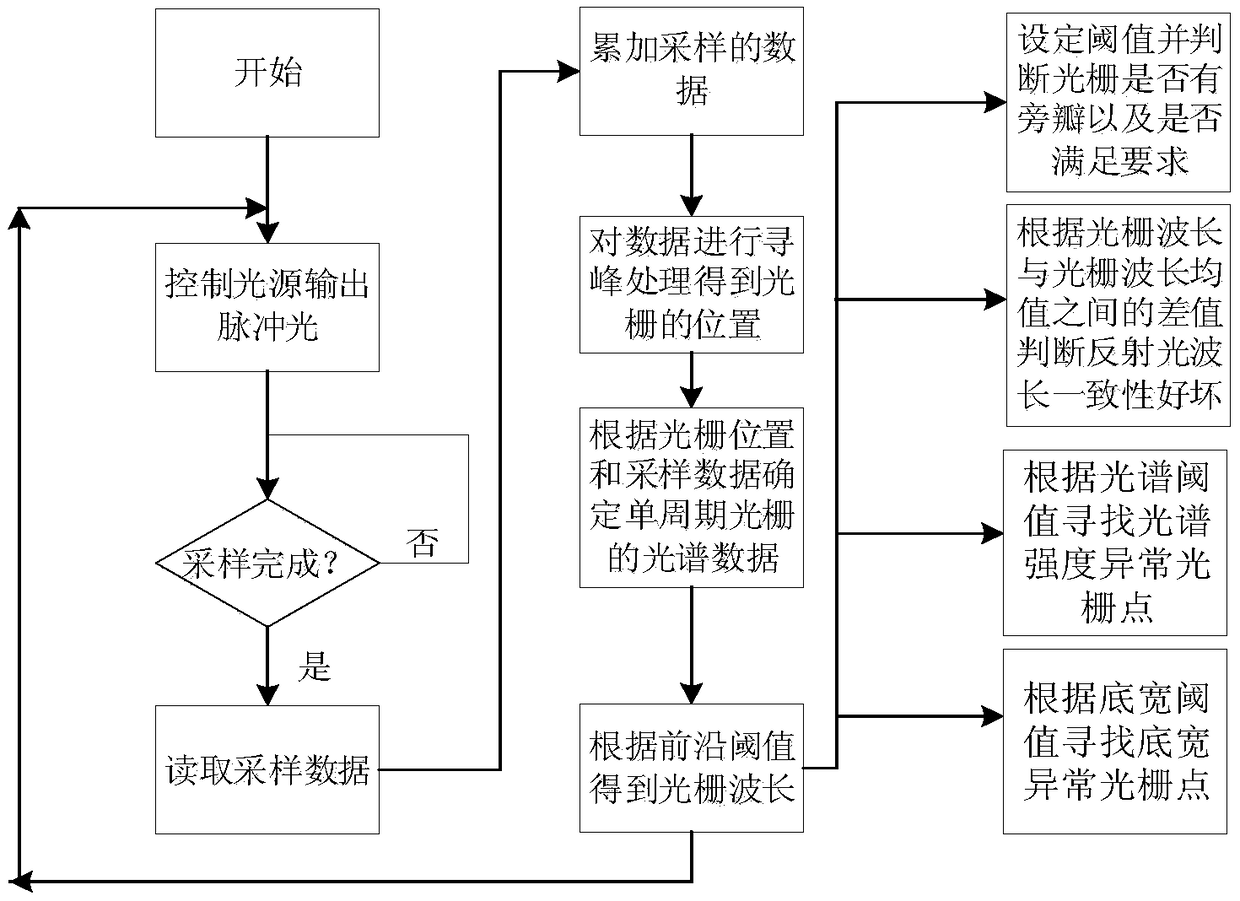

[0049] The block diagram of the online monitoring device for grating preparation of the present invention is as follows figure 1 As shown, the tunable frequency sweep light source module generates continuous frequency sweep light, and the pulse modulation module modulates the frequency sweep light generated by the light source into pulsed light. The pulsed light irradiates the equally spaced grating array and reflects the incoming photoelectric in the order of position. The conversion module, the photoelectric conversion module converts the reflected light signal into an electrical signal, the data acquisition module collects the converted electrical signal, and transmits the collected data to the signal processing module, and the signal processing module performs wavelength demodulation on the collected data And processing to realize the feedback of informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com