A method for making consecutive pathological sections of whole breast tumors at small intervals

A production method and mammary gland technology, which are applied in the fields of clinical medical experimental research and medical teaching, can solve the problems of unsatisfactory slicing results and difficulty in realizing sub-consecutive large slicing technology of whole breasts, and achieve easy realization of the slicing production process and excellent production efficiency. , the effect of reducing residue and toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Collect tumor specimens from patients with invasive ductal carcinoma of the breast, cut off the obvious excess fat and normal glandular tissue (obviously larger fat after the tumor specimen was obtained, etc.), keep the key parts of the tumor specimen as much as possible, and remove the irrelevant parts. The experience of clinicians can be implemented). Put the tumor specimens in a -80°C refrigerator for 30 minutes, take them out and cut them in parallel at intervals of 15 mm to obtain parallel cut specimen blocks, and mark the position of each cutting edge seam (determine the direction of each specimen and the direction before cutting). arrangement position). Place a piece of gauze on each parallel cut section of the cut specimen block; then, soak and fix it in 4% neutral formaldehyde solution for 24 hours, and the volume of neutral formaldehyde solution is about 22 times the sample volume.

[0071] The formula of neutral formaldehyde solution is as follows: 100 ml of...

Embodiment 2

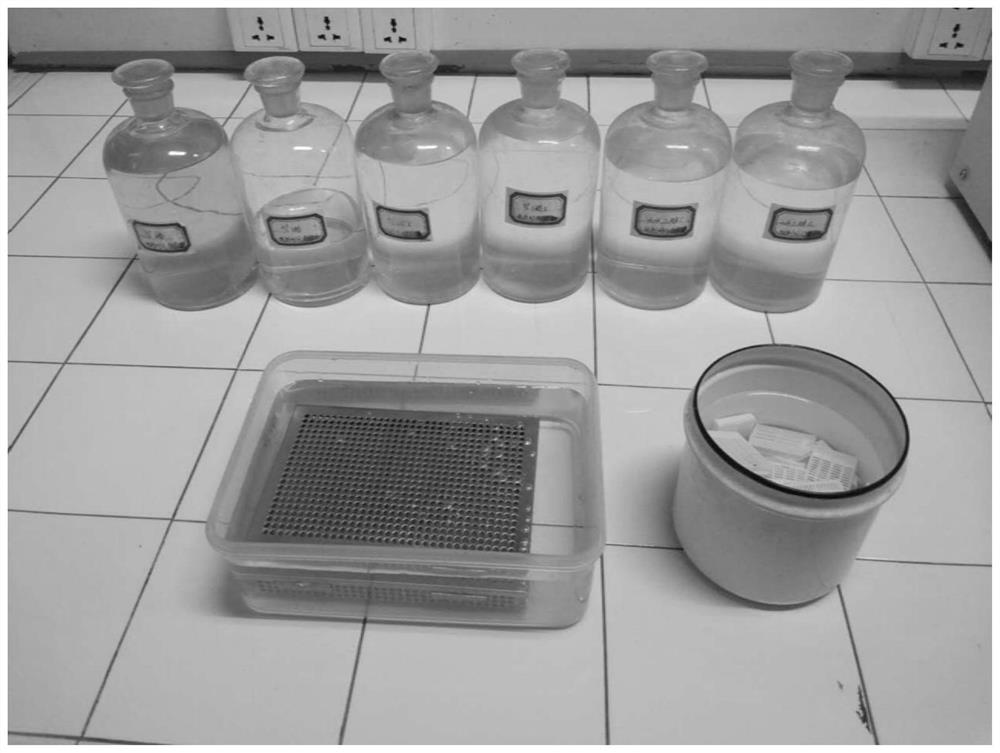

[0075] Referring to the scheme of Example 1, sub-continuous large slices of the whole mammary gland were made. Taking photos during production Figure 1-8 Shown, respectively, in the process of making sub-continuous large slices of the whole mammary gland figure 1 draw materials, figure 2 location markers, image 3 Gradient ethanol dehydration, Figure 4 xylene transparent, Figure 5 Dip Wax, Figure 6 Wax-soaked tissues, Figure 7 Embedded tissue, Figure 8 Tissue sections after HE staining.

[0076] The specific production process is as follows: collect tumor specimens from patients with invasive ductal carcinoma of the breast, and after complete mastectomy (before dissection of axillary lymph nodes), the surgeon will completely enucleate the tumor from the breast specimen, and cut off the surrounding obvious excess Adipose and normal glandular tissue. A small piece about 5×5×2.5mm (length×width×height) in the middle of the tumor was taken and sent to the patholog...

Embodiment 3

[0081] Summary Example 1-2 utilizes small-interval continuous histopathological sections of whole breast tumors to compare with conventional ones. There is no significant difference in HE staining results during the preparation process of Example 1-2, but it solves the problem of making large breast pathological sections. A series of technical problems occurred during the process, such as poor fixation effect, bending deformation, thick slices, poor quality, easy staining, and inability to observe under ordinary upright microscopes. The main reason is that during the production process, corresponding pretreatment preparations are carried out for the whole breast tumor specimen, which makes the sample dehydration, transparency, wax immersion and other effects better, and can achieve a better comprehensive treatment effect of the sample, making subsequent large slice production easier and more efficient. .

[0082] It also effectively shortens the pre-preparation time from 7 day...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com