Method for detecting amylase content of sugar cane product and application of method

A technology of amylase and sugar products, which is applied in the field of sugar cane sugar industry to achieve the effect of broadening the scope of application and efficient application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

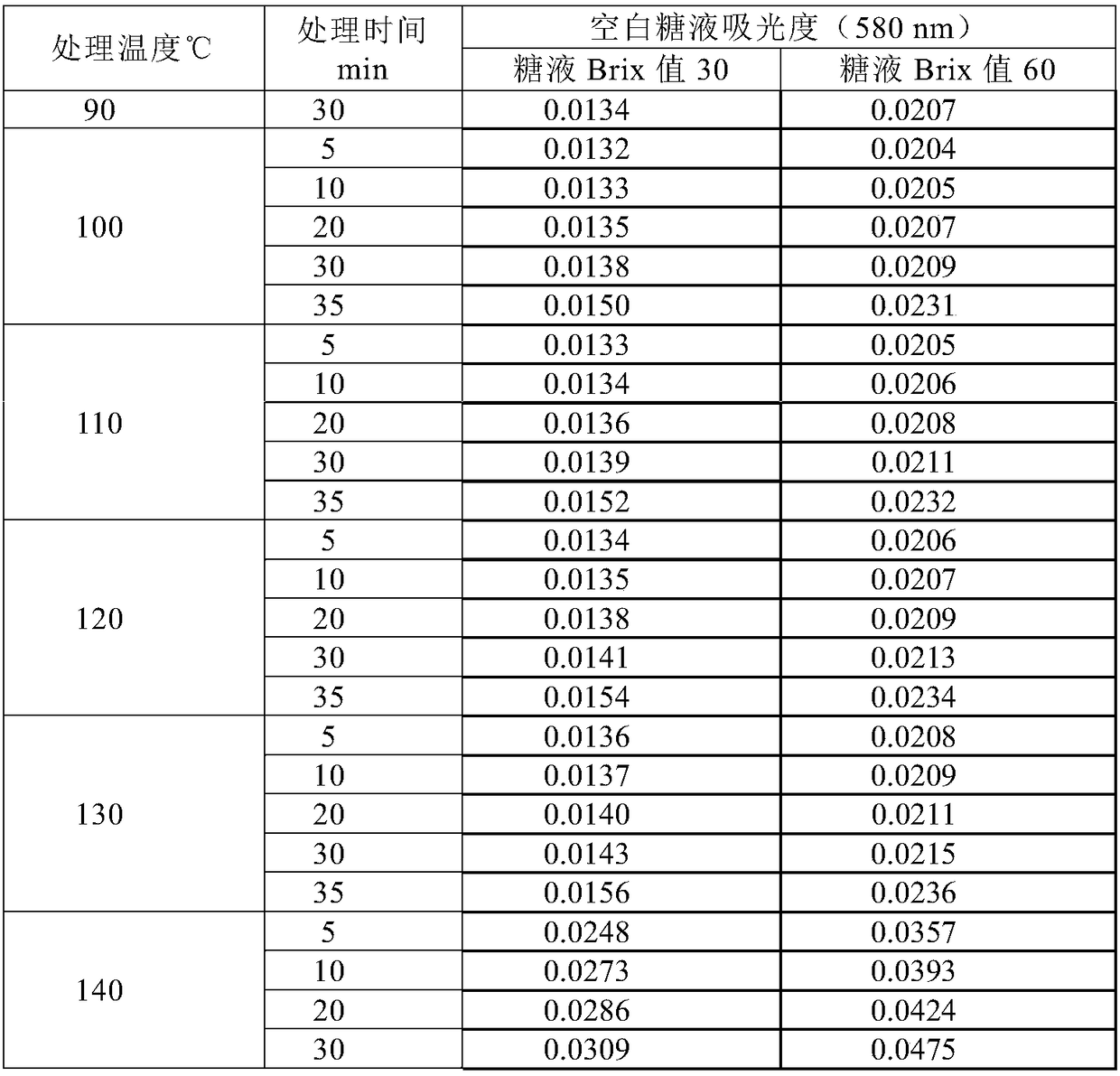

[0086] The preparation condition of embodiment 1 blank sugar product

[0087] High temperature treatment method:

[0088] Add medium-temperature α-amylase (purchased from Amano Amano Enzyme Trading (Shanghai) Co., Ltd.) to first-grade white granulated sugar (amylase was not used in the preparation process, that is, without amylase residue), and mixed to obtain starch Enzyme activity is 12500u / kg 糖 First-grade white granulated sugar containing amylase (hereinafter referred to as "initial sugar product"), wherein the addition ratio of amylase is 0.05mL of medium-temperature α-amylase per 20g of first-grade white granulated sugar. According to the treatment conditions (temperature and time) in Table 1, some of the initial sugar products prepared above were subjected to high temperature treatment in a forced air drying oven to obtain blank sugar products. Take 15g of each blank sugar product obtained through high temperature treatment and 15g of initial sugar product without hig...

Embodiment 2

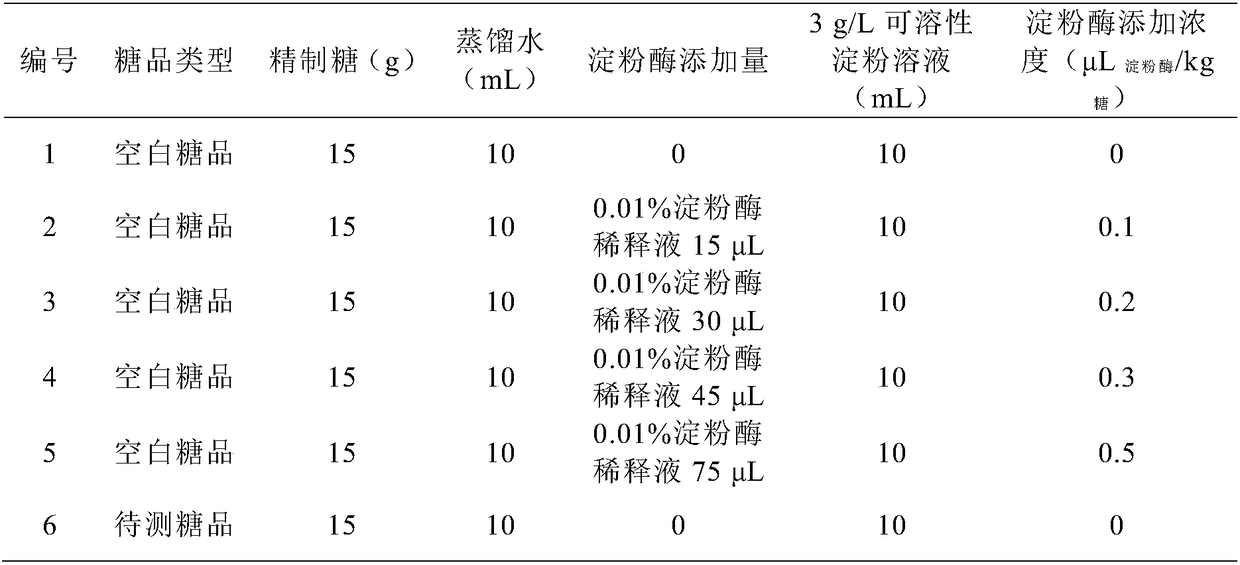

[0097] In the fourth effect evaporation section of the pressing workshop, add 10 ppm of high temperature resistant α-amylase (purchased from Amano Amano Enzyme Trading (Shanghai) Co., Ltd.) based on the total weight of the syrup, and then refine the production of the refining workshop according to the following steps The range of residual amylase content in the refined sugar is detected:

[0098] (1) Take 100g of refined sugar and place it in a vacuum drying oven, and process it at 130°C for 5 minutes to obtain a blank sugar product; at the same time, take 100g of untreated refined sugar as the sugar product to be tested;

[0099] (2) Weigh 15g of the blank sugar prepared in step (1) and place them in five 250mL ground-mouth hammer bottles, and weigh 15g of the sugar to be tested and place them in one 250mL ground-mouth hammer bottle 10 mL of distilled water was added to the above-mentioned 6 Erlenmeyer flasks, dissolved and mixed evenly, so as to prepare a blank sugar solutio...

Embodiment 3

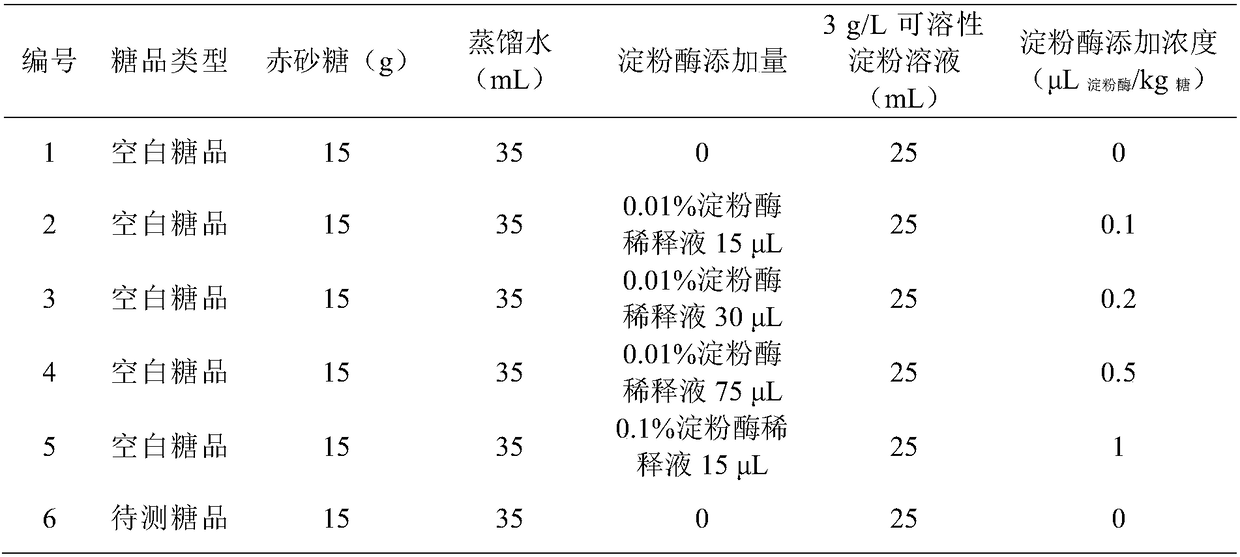

[0109] In the fifth effect evaporation section of the pressing workshop, based on the total weight of the initial pressed juice, add 10ppm of mesophilic α-amylase (purchased from Amano Amano Enzyme Trading (Shanghai) Co., Ltd.), according to the following steps for the obtained The range of residual amylase content in brown sugar is tested:

[0110] (1) Take 100g of brown sugar and place it in a vacuum drying oven, and process it at 100°C for 60 minutes to obtain a blank sugar; at the same time, take 100g of untreated brown sugar as the sugar to be tested

[0111] (2) Weigh 15g of the blank sugar prepared in step (1) and place them in five 250mL ground-mouth hammer bottles, and weigh 15g of the sugar to be tested and place them in one 250mL ground-mouth hammer bottle , add 35mL of distilled water to the above 6 Erlenmeyer flasks, dissolve and mix evenly, and prepare the blank sugar solution and the sugar solution to be tested with a Brix value of 30;

[0112] (3) Regulate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com