A thermal oxidation method for crystalline silicon solar cells

A crystalline silicon solar cell and thermal oxidation technology, applied in the field of solar cells, can solve the problems of unsatisfactory phosphorus atom redistribution effect, poor repair effect of dangling bonds, surface lattice defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

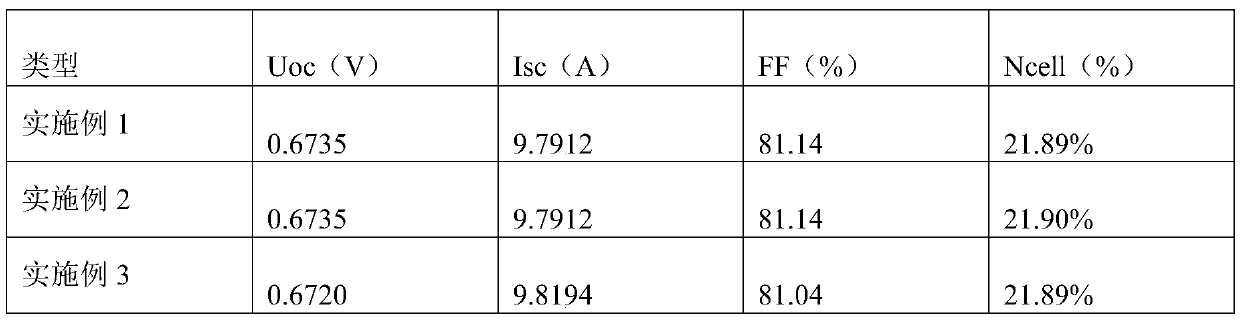

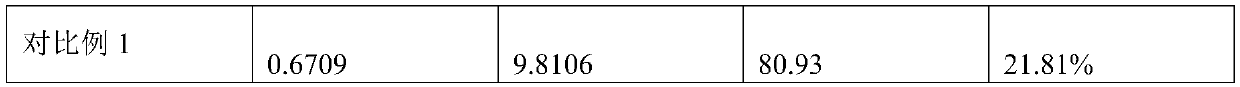

Embodiment 1

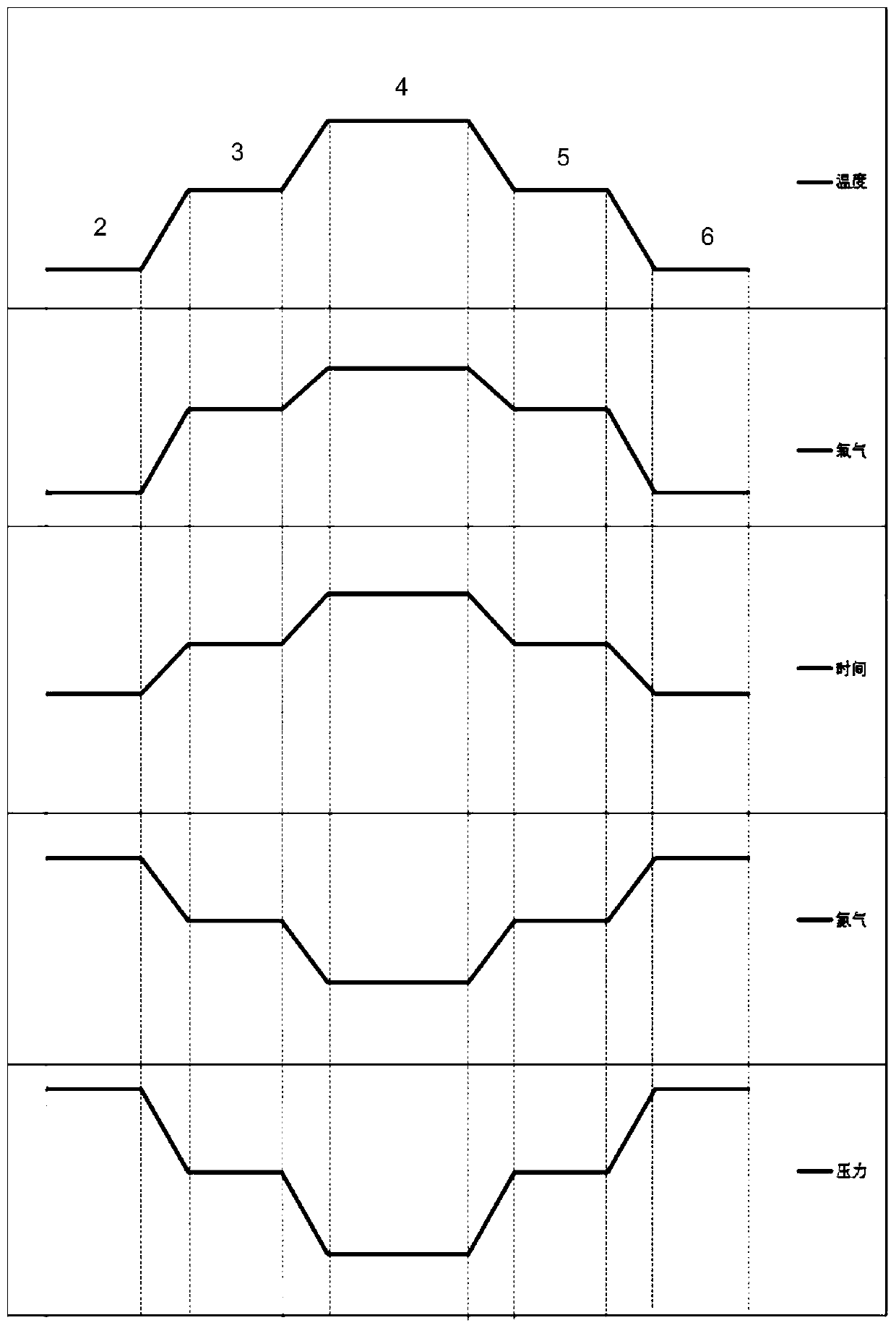

[0057] The silicon wafers after diffusion and etching cleaning are inserted into the quartz boat, sent into the oxidation furnace, heated to 680°C, and 10slm of nitrogen gas is introduced for 10 minutes, so that the gas pressure in the furnace tube reaches 580mbar;

[0058] Introduce nitrogen and oxygen, the nitrogen inflow rate is 1800sccm, the oxygen inflow rate is 380sccm, the inflow time is 8min, the oxidation furnace temperature is controlled at 680°C, and the furnace body pressure is 580mbar;

[0059] Introduce nitrogen and oxygen, the nitrogen inflow rate is 1300sccm, the oxygen inflow rate is 780sccm, and the inflow time is 13 minutes. The temperature of the oxidation furnace is controlled to 780°C, and the furnace body pressure is 280mbar;

[0060] Introduce nitrogen and oxygen, the nitrogen inflow rate is 800sccm, the oxygen inflow rate is 950sccm, and the inflow time is 18min. The temperature rise of the oxidation furnace is controlled to 880°C, and the furnace body pr...

Embodiment 2

[0065] After diffusion and etching, the silicon wafer is inserted into the quartz boat, sent into the oxidation furnace, heated to 700 ° C, and 10 slm of nitrogen gas is introduced for 10 minutes to make the gas pressure in the furnace tube reach 600 mbar;

[0066] Introduce nitrogen and oxygen, the nitrogen inflow rate is 2000sccm, the oxygen inflow rate is 400sccm, the inflow time is 10min, the oxidation furnace temperature is controlled at 700°C, and the furnace body pressure is 600mbar;

[0067] Introduce nitrogen and oxygen, the nitrogen inflow rate is 1500sccm, the oxygen inflow rate is 800sccm, and the inflow time is 15min. The temperature of the oxidation furnace is controlled to 800°C, and the furnace body pressure is 300mbar;

[0068] Introduce nitrogen and oxygen, the nitrogen inflow rate is 1000 sccm, the oxygen inflow rate is 1000 sccm, and the inflow time is 20 minutes. The temperature of the oxidation furnace is controlled to 900 ° C, and the furnace body pressur...

Embodiment 3

[0073] The silicon wafers after diffusion and etching cleaning are inserted into the quartz boat, sent into the oxidation furnace, heated to 720 ° C, and 10 slm of nitrogen gas is introduced for 10 minutes to make the gas pressure in the furnace tube reach 620 mbar;

[0074] Introduce nitrogen and oxygen, the nitrogen inflow rate is 2200sccm, the oxygen inflow rate is 420sccm, the inflow time is 12min, the oxidation furnace temperature is controlled at 720°C, and the furnace body pressure is 620mbar;

[0075] Introduce nitrogen and oxygen, the amount of nitrogen inflow is 1700sccm, the amount of oxygen inflow is 820sccm, and the inflow time is 18min. The temperature of the oxidation furnace is controlled to 800°C, and the pressure of the furnace body is 320mbar;

[0076] Introduce nitrogen and oxygen, the nitrogen inflow rate is 1200sccm, the oxygen inflow rate is 1050sccm, and the inflow time is 25min. The temperature rise of the oxidation furnace is controlled to 920°C, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com