Sour cream obtained by cooperative probiotic fermentation and containing rich active bacteria and preparation method thereof

A technology of probiotics and active bacteria, applied in the field of fermentation engineering, can solve the problems of increasing the number of probiotics in sour cream, and the probiotics cannot be fermented, etc., and achieves the effects of increasing the number of probiotics, low production cost, and small equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method involved in the following examples is as follows:

[0049] The preparation method of the probiotic bacteria liquid: draw the probiotic bacteria liquid from the glycerol bacteria preservation tube, inoculate it into a medium suitable for the proliferation of lactic acid bacteria (for example: LAB medium, MRS medium or RCM medium), and then incubate at a temperature of 36-42°C, The activation culture is carried out under anaerobic conditions for 18-36 hours, and the above-mentioned activation operation is repeated 2-4 times to obtain an activated probiotic bacterial liquid.

[0050] The preparation method of probiotic bacteria slime: first absorb the probiotic bacteria liquid from the glycerin bacteria preservation tube, inoculate it into the medium suitable for the proliferation of lactic acid bacteria, and then carry out activation culture at a temperature of 36-42°C and anaerobic conditions for 18-36 hours, and repeat the above-mentioned activatio...

Embodiment 1

[0080] Example 1: Fermented sour cream with fermentation agent Lactobacillus plantarum CCFM8661 (CGMCC No.5494)

[0081] Specific steps are as follows:

[0082] (1) Preparation of starter

[0083] Lactococcus lactis subsp. diacetyl bacteria powder and Leuconostoc enterococci subsp. cremoris bacteria powder were mixed according to the mass ratio of 1:1 to obtain starter powder. The total number of viable bacteria in the starter powder was 5 ×10 9 cfu / g;

[0084] (2) Preparation of cream

[0085] Homogenize the cream with a milk fat content of 35% under the condition of 14MPa~21MPa, collect the homogenized cream in a sterilized edible beaker, after homogenization, cover the beaker with 8 layers of gauze, and pasteurize at 82°C for 30min;

[0086] (3) Starter fermented sour cream

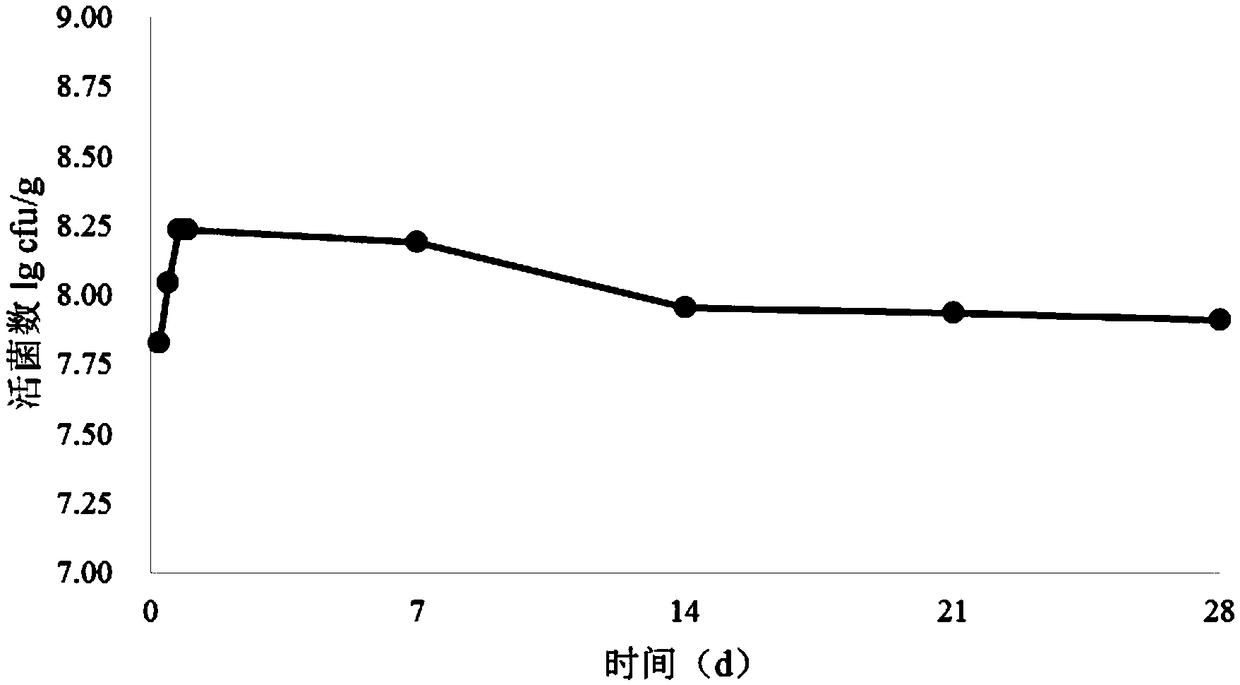

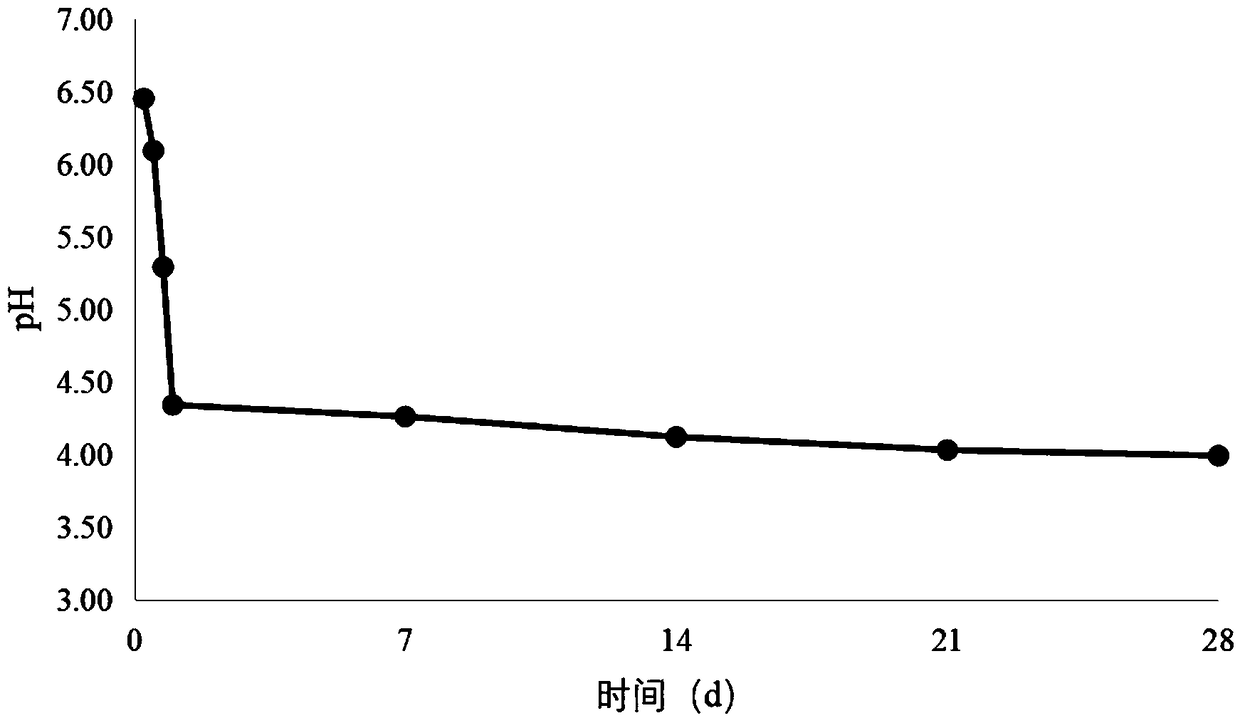

[0087] Treat that cream is cooled to 21 ℃, add the starter powder that quality is cream 0.2% and 0.01% live bacteria number is 3.1 * 10 11 cfu / g Lactobacillus plantarum CGMCC No.5494 bacterial po...

Embodiment 2

[0093] Embodiment 2: fermentation agent cooperates Lactobacillus rhamnosus to ferment sour cream

[0094] Specific steps are as follows:

[0095] (1) Preparation of starter

[0096] Lactococcus lactis subsp. diacetyl bacteria powder and Leuconostoc enterococci subsp. cremoris bacteria powder were mixed according to the mass ratio of 1:1 to obtain starter powder. The total number of viable bacteria in the starter powder was 5 ×10 9 cfu / g;

[0097] (2) Preparation of cream

[0098]Homogenize the cream with a milk fat content of 35% under the condition of 14MPa~21MPa, collect the homogenized cream in a sterilized edible beaker, after homogenization, cover the beaker with 8 layers of gauze, and pasteurize at 82°C for 30min;

[0099] (3) Starter fermented sour cream

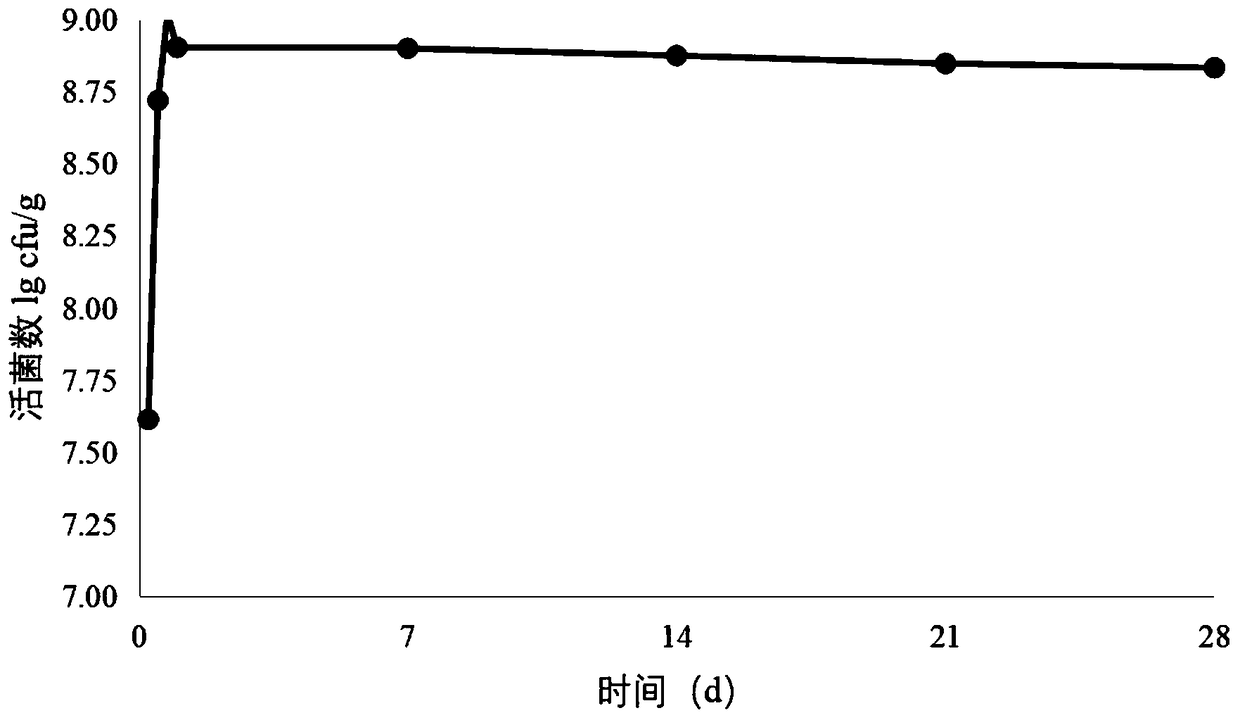

[0100] When the cream is cooled to 21°C, add 0.2% starter powder and 0.3% live bacteria to the cream to be 8×10 10 The cfu / g Lactobacillus rhamnosus sludge was fermented at 21° C. for 24 hours to obtain fermente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com