Guava fruit and leaf extract cyclodextrin inclusion compound and preparation method and application thereof

A technology of cyclodextrin inclusion compound and leaf extract, which is applied in the fields of application, food science, food ultrasonic treatment, etc., to achieve the effect of convenient consumption, easy absorption by human body, and various tastes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

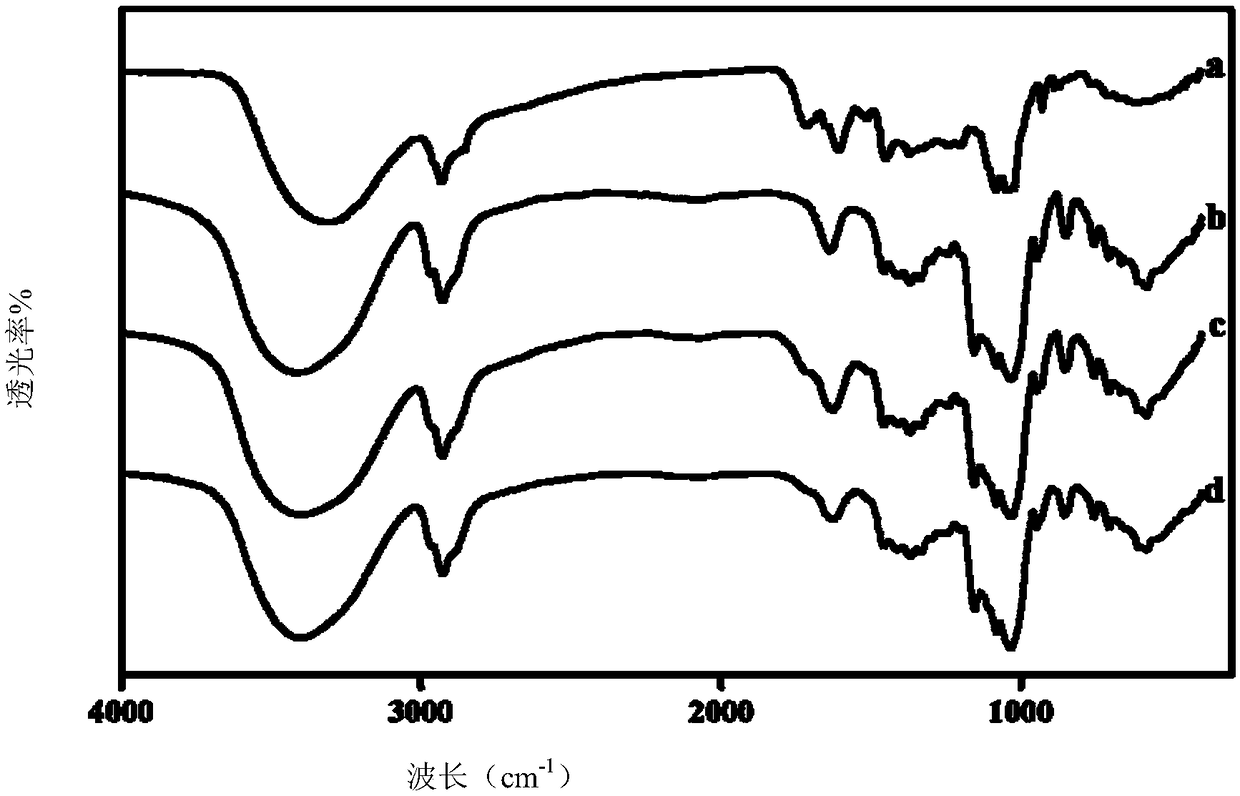

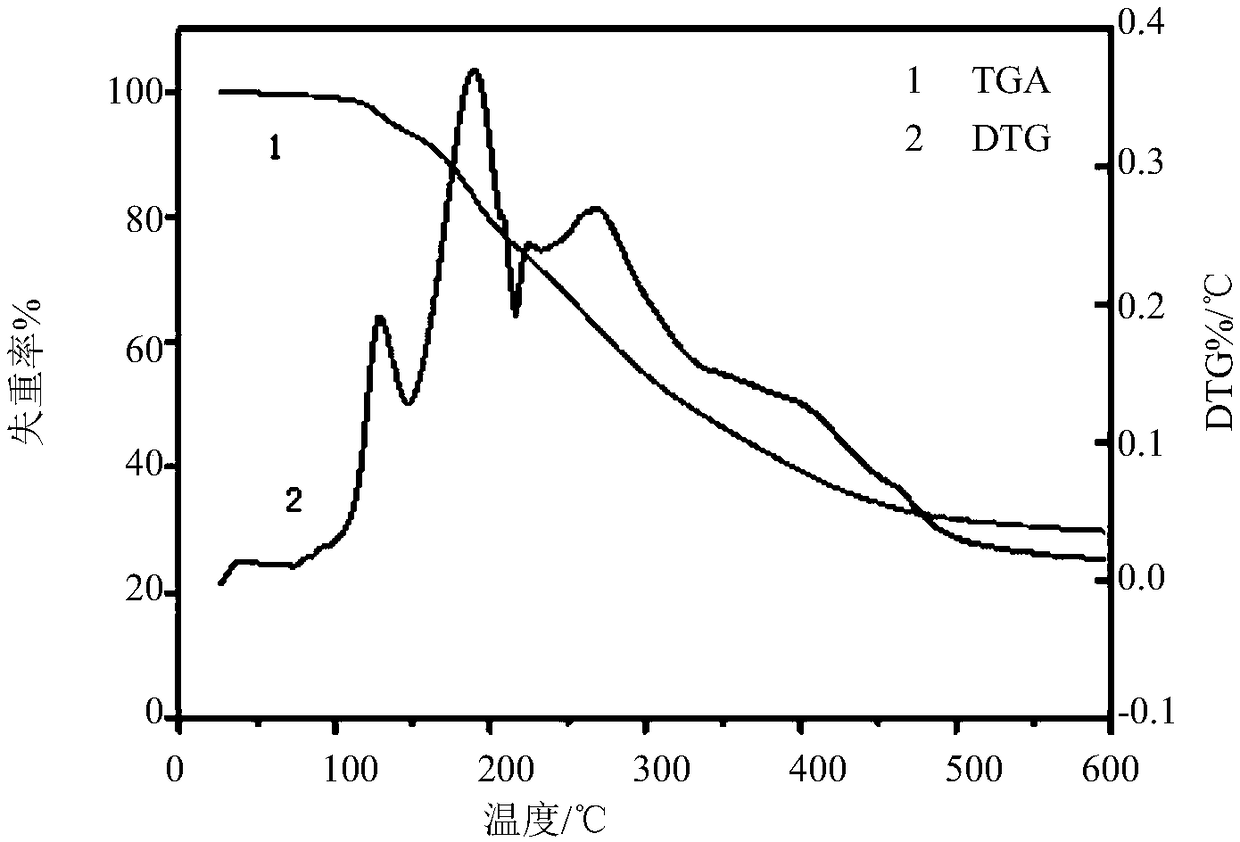

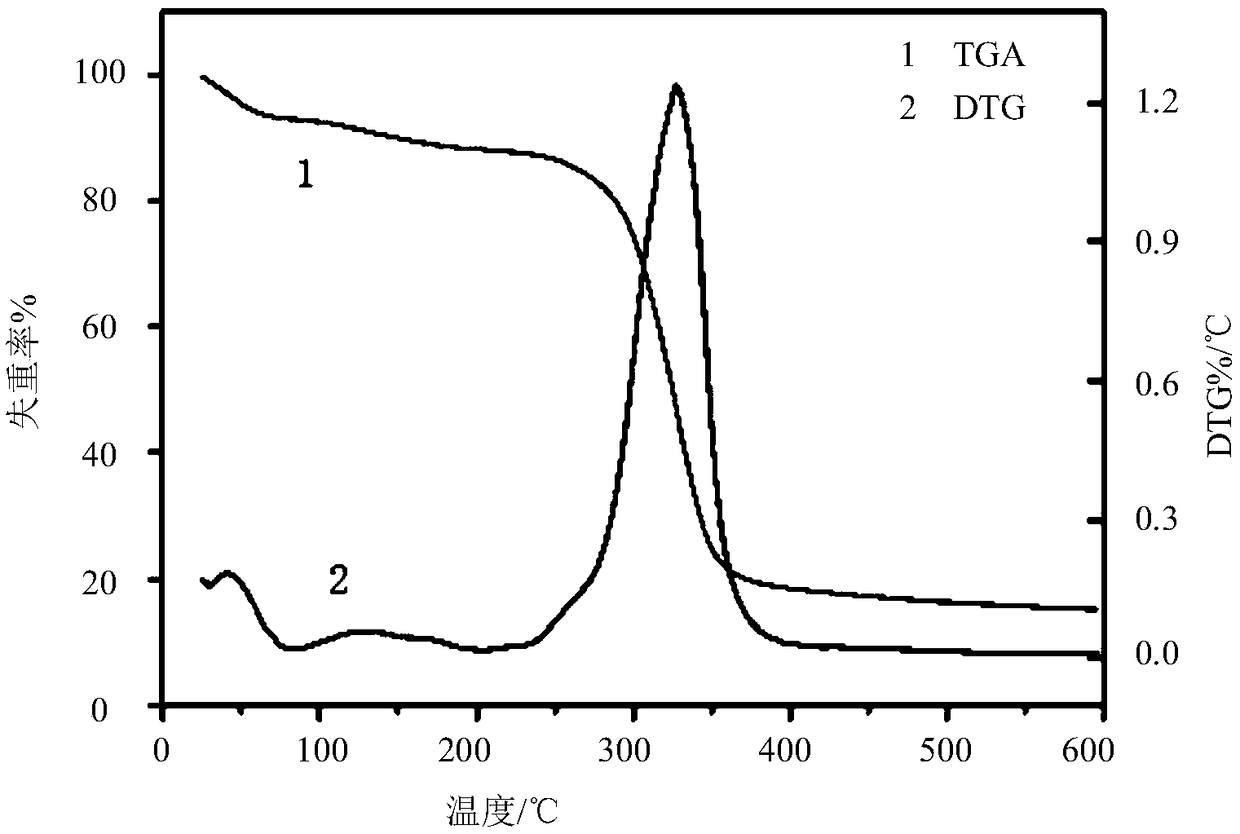

Image

Examples

Embodiment 1

[0053] Weigh 100 g of guava leaves, wash and dry, break into lumps, add 1000 mL of 70% (v / v) edible ethanol, and ultrasonically extract for 30 min with a power of 300 W to obtain an extract. Add the extract to a vacuum rotary evaporator, evaporate and concentrate until the volume is about 30% of the original volume, add 10g of hydroxypropyl-β-cyclodextrin, mix well, place in a dark place, and use 120W power for continuous ultrasonication for 30 minutes. The temperature is 35°C. After the ultrasonication is over, the temperature is controlled at 50°C and magnetically stirred at a speed of 100rpm for 6h. During the stirring process, the pH of the solution is adjusted to maintain at 3-4, and then filtered through a 0.45μm water filter membrane to elute the unincluded extract The filtrate was cooled to 4°C, then placed in a -80°C ultra-low temperature refrigerator for 2 hours, placed in a freeze dryer, and freeze-dried overnight to obtain the inclusion complex of hydroxypropyl-β-cy...

Embodiment 2

[0055]Weigh 100 g of guava fruit slices, wash and dry, break into lumps, add 1000 mL of 70% (v / v) edible ethanol, and ultrasonically extract for 30 min with a power of 300 W to obtain an extract. Add the extract to a vacuum rotary evaporator, evaporate and concentrate to about 30% of the original volume, add 15g of hydroxypropyl-β-cyclodextrin, mix well, place in a dark place, and use 120W power for continuous ultrasonication for 30min at a temperature of 35 ℃, after the end of ultrasound, control the temperature at 60 ℃, magnetically stir at 100rpm for 6h, adjust the pH of the solution at 3-4 during the stirring process, and then filter through a 0.45μm water filter to elute the unincluded extract. After cooling the filtrate to 4°C, put it into a -80°C ultra-low temperature refrigerator to continue freezing for 2 hours, put it into a freeze dryer, and freeze-dry it overnight to obtain the hydroxypropyl-β-cyclodextrin inclusion complex of guava fruit extract dry powder.

Embodiment 3

[0057] Weigh 100g of guava fruit slices, wash and dry them, break them into lumps, add 1000mL of 100℃ hot water, let stand for leaching for 90min, and obtain the extract. Add the extract to a vacuum rotary evaporator, evaporate until concentrated to about 30% of the original volume, add 10g of γ-cyclodextrin, mix well, place in a dark place, stir magnetically at a speed of 100rpm at room temperature for 24h, pass through a 0.45μm Filtrate with an aqueous filter membrane to elute the unincluded extract, and directly spray-dry the filtrate to obtain the γ-cyclodextrin inclusion complex dry powder of the water extract of guava fruit slices.

[0058] The γ-cyclodextrin inclusion compound dry powder of the water extract of guava fruit slices obtained is mixed with citric acid and lactic acid according to the mass ratio of 5:2:1, dried, sealed and bagged to make a beverage infusion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com