Novel temperature-sensitive hydrogel-like sealant and lubricant for dental implant system

A temperature-sensitive hydrogel and implant system technology, which is applied in the field of new temperature-sensitive hydrogel-like sealants and lubricants, can solve the problem that the torque cannot be fully converted into preload, the friction coefficient of Teflon coating is small, and the stability of the abutment is affected. and other problems to achieve the effect of reducing micro-leakage, reducing growth space, and reducing the occurrence of tissue inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

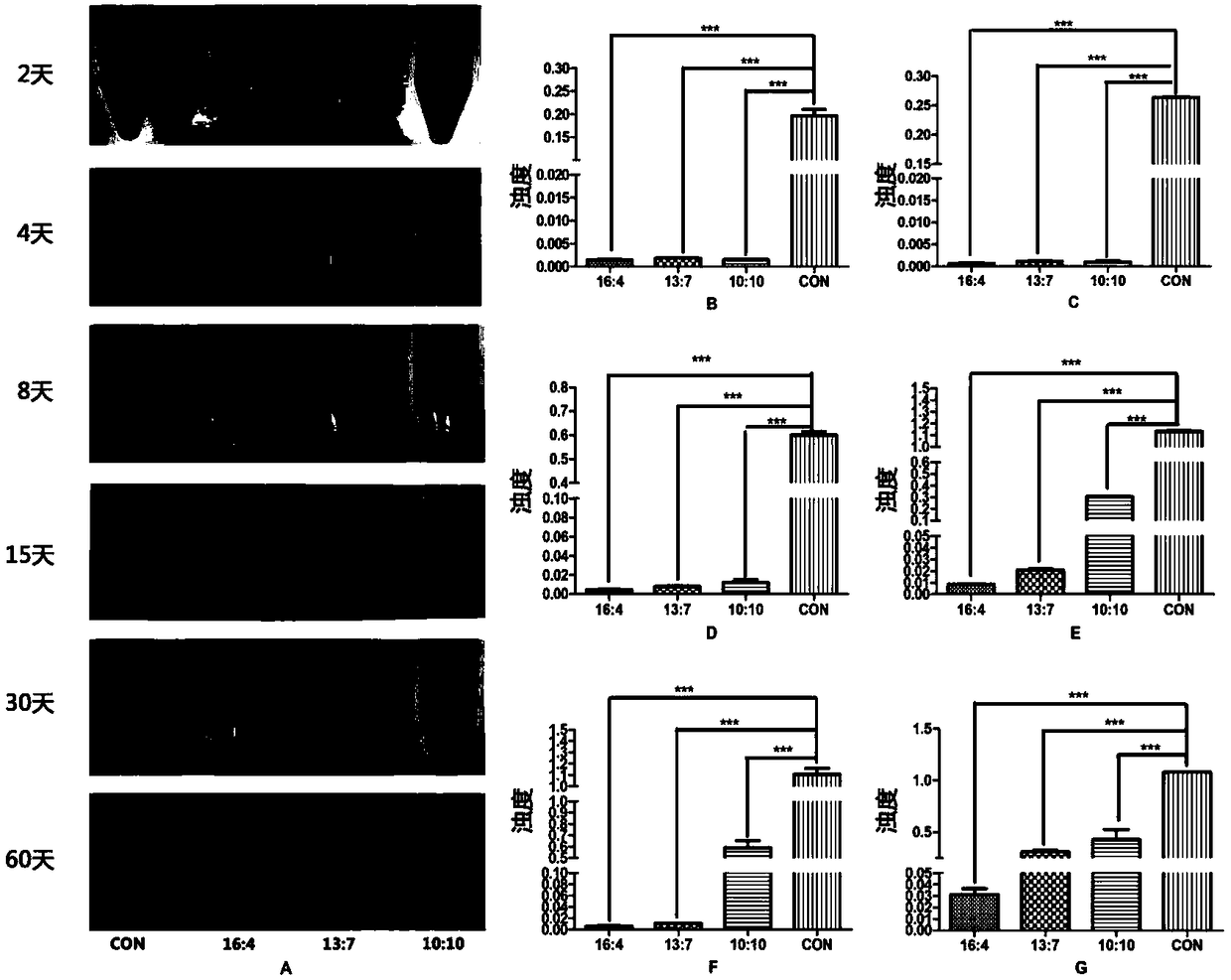

[0026] The chitosan temperature-sensitive hydrogel described in Examples 1 to 3 is prepared from chitosan, sodium β-glycerophosphate and povidone-iodine, and is applied to a dental implant system. The specific preparation process includes the following steps:

[0027] 1) The chitosan powder of 320mg is dissolved in 9ml (0.18M) glacial acetic acid and obtains chitosan solution, high temperature and high pressure sterilization; bacteria water) to obtain β-sodium glycerophosphate and povidone-iodine solution;

[0028] 2) Prepare 1ml thermosensitive hydrogel:

[0029] ①Mix a certain volume of chitosan solution and 100 μl povidone-iodine solution in a sterile EP tube, stir well to obtain solution A:

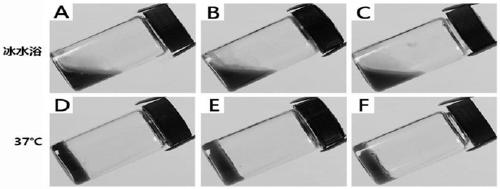

[0030] ②Solution A and a certain volume of β-glycerophosphate sodium solution (placed in a sterile EP tube) were bathed in ice water for 15 minutes at the same time;

[0031] ③Sodium β-glycerophosphate solution is slowly added to solution A drop by drop while stirring in an ice-wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com