A composite oil-absorbing material

An oil-absorbing material and mass ratio technology, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of poor oil-absorbing effect and low holding rate, achieve good oil-absorbing effect, reduce physical cross-linking degree, The effect of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

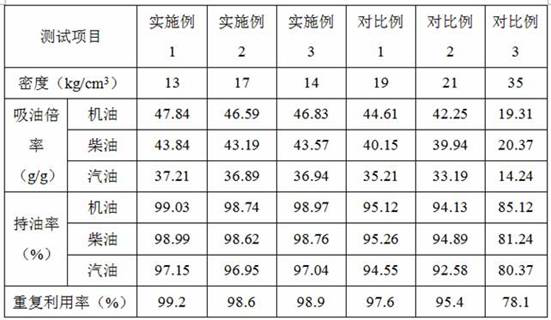

Examples

preparation example Construction

[0029] The preparation method of composite hydrophobic fiber airgel comprises the steps:

[0030] (1) After drying the cotton fiber in a vacuum oven at 60-80°C for 8-12 hours, add nano-Fe at a mass ratio of 3:0.1-0.3:15-25 3 o 4 , Reagent A, mixed with 500~800r / min magnetic force for 35~60min, transferred to a centrifuge and centrifuged at 3000~4000r / min for 10~15min, removed the centrifuged matter, and obtained cellulose liquid, put it in a water bath at 35~50℃, took Add 1-4% N,N-methylenebisacrylamide to the cellulose liquid, mix with 400-700r / min magnetic force for 30-55min, and let stand at room temperature for 4-6h to obtain a hydrogel, take water After the gel was washed with deionized water for 2 to 4 times, it was transferred to a freeze dryer at -40°C for 4 to 6 hours to obtain a cross-linked fiber hydrogel;

[0031] (2) Take the cross-linked fiber hydrogel in a closed desiccator, and place an open cup containing 1~3mL methyltrichlorosilane in the desiccator, and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com