Denitration catalyst and its preparation method

A denitrification catalyst and binder technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve the effect of wide source of raw materials, low manufacturing cost, and efficient comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

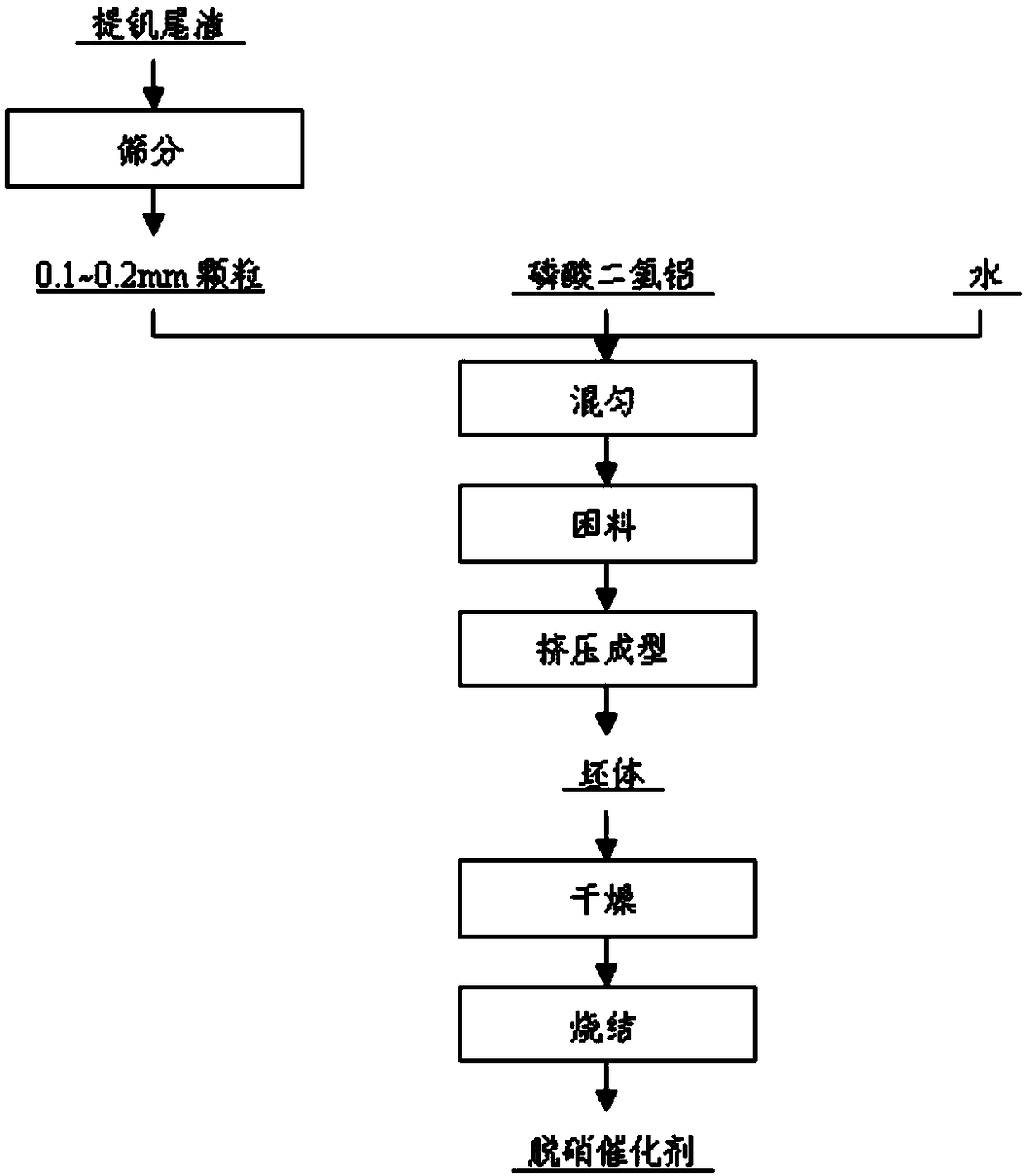

Method used

Image

Examples

Embodiment 1

[0040] 98 parts by weight of vanadium extraction tailings with a particle size of 0.1-0.2 mm, 2 parts by weight of aluminum dihydrogen phosphate and water are mixed for 2 hours to obtain a mixture; the mass content of water in the mixture is 3%;

[0041] Extruding the mixture using an extrusion molding machine, and the molding strength during the extrusion molding process is 5 MPa to obtain a green body;

[0042] The green body is dried at 110° C. and then sintered at 500° C. to form a denitration catalyst.

[0043] According to GB T 5072-2208 "Test Method for Compressive Strength of Refractories at Normal Temperature", the denitration catalyst prepared in Example 1 of the present invention was tested for compressive strength. The test result is that the denitration catalyst prepared in Example 1 of the present invention has a pressure resistance The strength is 8.2MPa.

[0044] The denitration efficiency of the denitration catalyst prepared in Example 1 of the present invention was t...

Embodiment 2

[0051] 95 parts by weight of vanadium extraction tailings with a particle size of 0.1-0.2 mm, 5 parts by weight of aluminum dihydrogen phosphate and water are mixed for 5 hours to obtain a mixture; the mass content of water in the mixture is 5%;

[0052] Extruding the mixture using an extrusion molding machine, and the molding strength during the extrusion molding process is 5 MPa to obtain a green body;

[0053] The green body is dried at 110° C. and then sintered at 500° C. to form a denitration catalyst.

[0054] According to the method described in Example 1, the compressive strength of the denitration catalyst prepared in Example 2 of the present invention was tested to be 8.2MPa, the optimal denitration temperature was 300-400°C, and the denitration efficiency was 48.5%.

Embodiment 3

[0056] 98 parts by weight of vanadium extraction tailings with a particle size of 0.1-0.2 mm, 2 parts by weight of aluminum dihydrogen phosphate and water are mixed for 3 hours to obtain a mixture; the mass content of water in the mixture is 3%;

[0057] Extruding the mixture using an extrusion molding machine, and the molding strength during the extrusion molding process is 3 MPa to obtain a green body;

[0058] The green body is dried at 110° C. and then sintered at 200° C. to form a denitration catalyst.

[0059] According to the method described in Example 1, the compressive strength of the denitration catalyst prepared in Example 3 of the present invention was tested to be 4.5 MPa, the optimal denitration temperature was 300-400° C., and the denitration efficiency was 55.5%.

[0060] It can be seen from the above examples that the present invention provides a method for preparing a denitration catalyst, including: mixing vanadium extraction tailings, a binder, and water to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com